Our PET bottle recycling line is an efficient and reliable solution designed specifically for the disposal of waste PET bottles. Its main purpose is to recycle various PET bottles into clean and impurity-free PET flakes, which can be used for secondary use and can also be sold at a good price.

The production range of this recycling line is wide, from 500kg/h to 6000kg/h, and can be customized according to customer needs to meet the needs of recycling projects of different scales. Below, we will take you to learn more about our PET bottle recycling machine.

PET Bottle Recycling Line Details

The configuration of the production line is a concern for many customers. The whole PET bottle recycling line includes a label removal machine, a PET bottle crushing machine, a plastic scrap washing machine, a sink float plastic separation, a PET flakes dewatering machine, etc. Through these processes, we help customers process waste PET bottles into recycled PET bottle sheets that meet their requirements.

As a reliable PET bottle recycling machine supplier, we have rich experience and have exported equipment to countries such as Nigeria, South Sudan, Congo, Saudi Arabia, and Mozambique. We tailor cleaning and recycling solutions based on the raw materials and needs of our customers, helping them effectively improve the quality and market competitiveness of recycled materials.

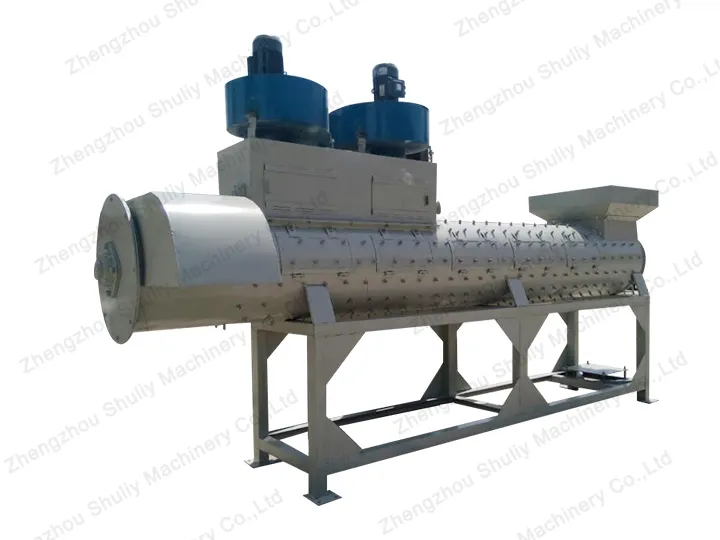

PET bottle recycling machine

Raw Material And Finished Product

The quality of raw materials and finished products for PET bottle recycling lines is of great concern to customers, as these two factors directly affect their recycling efficiency, product quality, and market competitiveness.

The color grades of recycled PET bottle flakes are pure white flakes, light blue flakes, green flakes, yellow flakes, and miscellaneous flakes in descending order. Different color grades of PET bottle flakes have different prices and applications in the market. Pure white and light blue flakes are usually more expensive due to their higher purity and wide range of applications.

High-quality recycled PET bottle flakes are more competitive in the market, able to meet the needs of more customers and expand market share. It is suitable for various high-demand applications, such as food packaging, textiles, and high-quality plastic products. Our PET bottle recycling line is fully capable of producing high-quality pure white and light blue PET bottle flakes.

Working Process Of PET Bottle Washing Line

Through efficient separation technology and multi-level cleaning, our PET bottle recycling machine significantly improves the quality of recycled PET bottle sheets, ensuring their stronger competitiveness in the market. The following is a detailed process flow for the PET bottle recycling line:

Removing Labels

Firstly, the collected used PET bottles are de-labelled. The de-labeling rate of PET bottle label removers is 98%, which can reduce the PVC content in PET bottle flakes to less than or equal to 100-300mg/kg, ensuring the quality of final PET bottle flakes.

Crushing

The PET bottles after delabelling enter the PET bottle crushing machine for crushing. The shredder crushes the PET bottles into small flakes for subsequent cleaning and separation processes.

The blades of this PET bottle crusher are made of 9Crsi with excellent wear resistance and high hardness, ensuring long-time efficient work and long-lasting cutting performance.

Washing

The washing process consists of several steps to ensure that the PET bottle flakes are thoroughly cleaned:

- Separation: The crushed PET bottles enter the sink float separation tank to separate the PET bottle flakes from the caps and labels using density separation technology. The machine can control polyolefin content ≤200-300(mg/kg).

- Hot washing: PET bottle flakes enter the PET flakes hot washing machine and are hot washed at high temperatures. Oil and impurities are removed by soaking in hot water and stirring and rubbing with lye. The water temperature is 85-90 degrees and the cleaning time is 30-45 minutes is optimal.

- Friction Washing: Residues on the surface of bottle flakes are further removed using a friction washer machine.

- Rinsing: Finally, after several rinses ensure that the PET bottle flakes are completely clean and free of residual impurities. This step of the cleaning can be controlled with a pH less than or equal to 8.0.

Drying

The cleaned PET bottle flakes are fed into the PET flakes dryer machine for drying. The dryer completely removes water from the bottle flakes by centrifugal force, ensuring that they are in a dry state for subsequent handling and storage. The drying degree of this machine can reach 95-98%.

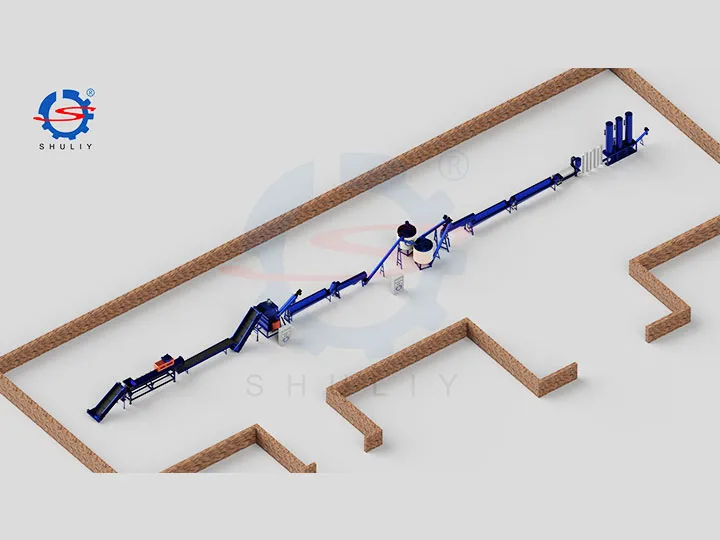

1000KG/H PET Bottle Recycling Plant Process

The following video shows our company’s 1000kg/h PET bottle recycling plant recycling process. We can also provide smaller or larger output according to customer needs, such as 500kg/h, 3000kg/h

1000KG/H PET Bottle Washing Line Specifications

Taking the placement of “I” shaped equipment as an example, the factory covers an area of approximately 60 meters in length, 2.8 meters in width, and 4 meters in height. 6-8 manual workers are required. Below are the detailed parameters of the key PET bottle recycling machine.

| Item | Specifications | Qty |

| PET bottle label remover | Voltage: 380V, 50HZ, 3-phase electric Power: 15+3+1.5kw Barrel length: 4.3m, diameter: 0.63m Round bottle off-label rate 98% PVC content/(mg/kg) ≤ 100-300 (mg/kg) | 1 |

| PET bottle crusher | Voltage: 380V, 50HZ, 3-phase electric Power: 37+1.5KW+1.5kw Tool: 9Crsi Production: 1000KG/H Screen size: 18mm Knife plate thickness: 40mm | 1 |

| Sink float separation tank | Voltage: 380V, 50HZ, 3-phase electric Power: 3KW Outer wall thickness: 4mm Blade thickness: 6mm Equipment size: 5000 * 1000 * 1000mm Control polyolefin content ≤ 200-300 (mg/kg) | 3 |

| PET flakes hot washing machine | Voltage: 380V, 50HZ, 3-phase electric Motor 4kw Electromagnetic heating power: 80KW Height: 2000mm, diameter: 1300mm | 2 |

| Friction washer machine | Voltage: 380V, 50HZ, 3-phase electric Power: 7.5KW Barrel length: 3000mm, diameter: 400mm Blade thickness: 6mm | 2 |

| PET flakes dryer machine | Voltage: 380V, 50HZ, 3-phase electric Power: 15KW Remove moisture and achieve a drying degree of around 95-98% | 1 |

Wherein the drying duct can control the moisture to less than or equal to 0.5-1%. The wind separator is used to remove the residual fine labels and dust, it can control the impurity content ≤ 300-500mg/kg and powder content ≤ 2000-3000mg/kg.

These two machines are suitable for production scenarios with larger outputs or higher requirements for the final products.

Global Cases of PET Bottle Recycling Line

PET Bottle Recycling Plant Successfully Shipped to Mozambique

Shuliy has successfully concluded a deal with an important customer in Mozambique. This customer from Mozambique is engaged in the plastic recycling business and has ordered a 1000kg/h PET washing plant. After the machine arrived, they also took feedback pictures of us, expressing their satisfaction with our equipment and service. Below are some shipping pictures.

Plastic Bottle Washing Plant Installed in Nigeria

A customer in Nigeria customized the plastic bottle recycling machine and plastic pelletizing equipment from Shuliy to process local waste.

Shuliy’s technical team traveled to Nigeria to install and commission a plastic bottle recycling machine for a Nigerian customer to process local waste, providing not only professional technical support but also a series of customized adjustments according to the customer’s actual needs, to ensure that the equipment can meet the customer’s production requirements to the maximum extent possible.

Our PET Bottle Recycling Machine Service

Our company not only provides an efficient PET bottle recycling line but also provides comprehensive services to customers to ensure that you achieve the best results in the recycling and reuse process. Here are the services we provide for you:

Customized plan: Based on your specific needs, we will tailor a PET bottle washing line plan to ensure that the equipment configuration, production capacity, and process flow best meet your production requirements.

Make an appointment to visit our factory: You can make an appointment to visit our factory and witness our production strength and equipment quality firsthand. We will arrange for professionals to explain the working principle and advantages of the equipment to you, and answer all your questions.

On-site installation assistance: We provide on-site installation services, with an experienced technical team visiting your factory to ensure that the equipment is installed and debugged properly, helping you quickly start production.

After-sales service: We promise to provide you with long-term after-sales service, including equipment maintenance, technical support, and component supply. No matter what problems you encounter during use, our after-sales team will respond promptly.

PET bottle washing recycling machine

Plastic Bottle Recycle Machine Price

Are you curious about how to process PET plastic? And how much do PET bottle recycling lines cost? Usually, the PET recycling line price will vary according to the machine model, processing capacity, and production efficiency. If you are interested in the plastic bottle recycling machine or want to know the price information, please feel free to contact us, we will be happy to provide you with a detailed inquiry service to meet your needs.

The Necessity of PET Bottle Recycling Line

The annual amount of waste plastics in China is about 5 million tons, plastic has corrosion resistance, and not easy to-decompose characteristics, plastic waste rain for a long time, and the toxic additives in plastic will enter the groundwater, rivers, and lakes caused by pollution, endangering human health!

Therefore, waste plastic has caused a lot of potential harm to the environment and has become an environmental issue of concern to all sectors of society in China. This characteristic and its small weight and large volume in the garbage determines that its final disposal is not suitable for landfill.

However, it is a macromolecular material with high calorific value, recycling is in line with the basic national policy of sustainable development in China, and can also make full use of its intrinsic value, save resources, and protect the environment.

Significance of PET Bottle Recycling Line

Protect The Environment

Improper disposal of waste plastics can cause pollution to the environment and deterioration of the local ecological environment. By PET bottle recycling line, we can reduce its impact on the environment, prevent pollution, and protect the ecological environment.

Saving Resources

The production of plastics consumes a lot of resources such as PET role, and the recycling of waste plastics can precisely reuse these resources and achieve the purpose of saving. In the process of processing waste plastics, plastics can be recycled and reprocessed to make new plastic products, thus achieving the purpose of saving resources.

Cost Reduction

Compared to the production of new plastics, recycling waste plastics is less expensive. At the same time, recycling waste plastics can bring additional revenue to manufacturing companies.

Prospect of Plastic Bottle Recycling Machine

Currently, recycling waste plastics has become a very important task worldwide. Governments and enterprises have invested a lot of human and material resources to promote the development of waste plastics recycling.

In China, the waste plastic recycling industry is also developing rapidly. The government has introduced a series of policies and measures to support the recycling of waste plastics, which can also promote the development of environmental protection.

At the same time, domestic enterprises have actively invested in the recycling industry to promote the concept of reusing waste plastics, forming the scale of the waste plastics recycling industry, and the recycling of plastic scrap also brings more resources to enterprises. Therefore, the PET bottle recycling line market has a broad prospect and a promising future.