Our PET bottle recycling line is an efficient and reliable solution designed specifically for the disposal of waste PET bottles. Its main purpose is to recycle various PET bottles into clean and impurity-free PET flakes, which can be used for secondary use and can also be sold at a good price.

The production range of this recycling line is wide, from 500kg/h to 6000kg/h, and can be customized according to customer needs to meet the needs of recycling projects of different scales. Below, we will take you to learn more about our PET bottle recycling machine.

PET Bottle Recycling Line Details

The configuration of the production line is a concern for many customers. The whole PET bottle recycling line includes a label removal machine, a PET bottle crushing machine, a plastic scrap washing machine, a sink float plastic separation, a PET flakes dewatering machine, etc. Through these processes, we help customers process waste PET bottles into recycled PET bottle sheets that meet their requirements.

As a reliable PET bottle recycling machine supplier, we have rich experience and have exported equipment to countries such as Nigeria, South Sudan, Congo, Saudi Arabia, and Mozambique. We tailor cleaning and recycling solutions based on the raw materials and needs of our customers, helping them effectively improve the quality and market competitiveness of recycled materials.

ماكينة إعادة تدوير زجاجات PET

Raw Material And Finished Product

The quality of raw materials and finished products for PET bottle recycling lines is of great concern to customers, as these two factors directly affect their recycling efficiency, product quality, and market competitiveness.

The color grades of recycled PET bottle flakes are pure white flakes, light blue flakes, green flakes, yellow flakes, and miscellaneous flakes in descending order. Different color grades of PET bottle flakes have different prices and applications in the market. Pure white and light blue flakes are usually more expensive due to their higher purity and wide range of applications.

High-quality recycled PET bottle flakes are more competitive in the market, able to meet the needs of more customers and expand market share. It is suitable for various high-demand applications, such as food packaging, textiles, and high-quality plastic products. Our PET bottle recycling line is fully capable of producing high-quality pure white and light blue PET bottle flakes.

Working Process Of PET Bottle Washing Line

Through efficient separation technology and multi-level cleaning, our PET bottle recycling machine significantly improves the quality of recycled PET bottle sheets, ensuring their stronger competitiveness in the market. The following is a detailed process flow for the PET bottle recycling line:

Removing Labels

Firstly, the collected used PET bottles are de-labelled. The de-labeling rate of PET bottle label removers is 98%, which can reduce the PVC content in PET bottle flakes to less than or equal to 100-300mg/kg, ensuring the quality of final PET bottle flakes.

سحق

The PET bottles after delabelling enter the آلة سحق زجاجة PET for crushing. The shredder crushes the PET bottles into small flakes for subsequent cleaning and separation processes.

The blades of this PET bottle crusher are made of 9Crsi with excellent wear resistance and high hardness, ensuring long-time efficient work and long-lasting cutting performance.

غسل

The washing process consists of several steps to ensure that the PET bottle flakes are thoroughly cleaned:

- Separation: The crushed PET bottles enter the sink float separation tank to separate the PET bottle flakes from the caps and labels using density separation technology. The machine can control polyolefin content ≤200-300(mg/kg).

- Hot washing: PET bottle flakes enter the PET flakes hot washing machine and are hot washed at high temperatures. Oil and impurities are removed by soaking in hot water and stirring and rubbing with lye. The water temperature is 85-90 degrees and the cleaning time is 30-45 minutes is optimal.

- Friction Washing: Residues on the surface of bottle flakes are further removed using a friction washer machine.

- Rinsing: Finally, after several rinses ensure that the PET bottle flakes are completely clean and free of residual impurities. This step of the cleaning can be controlled with a pH less than or equal to 8.0.

تجفيف

The cleaned PET bottle flakes are fed into the PET flakes dryer machine for drying. The dryer completely removes water from the bottle flakes by centrifugal force, ensuring that they are in a dry state for subsequent handling and storage. The drying degree of this machine can reach 95-98%.

1000KG/H PET Bottle Recycling Plant Process

The following video shows our company’s 1000kg/h PET bottle recycling plant recycling process. We can also provide smaller or larger output according to customer needs, such as 500kg/h, 3000kg/h

1000KG/H PET Bottle Washing Line Specifications

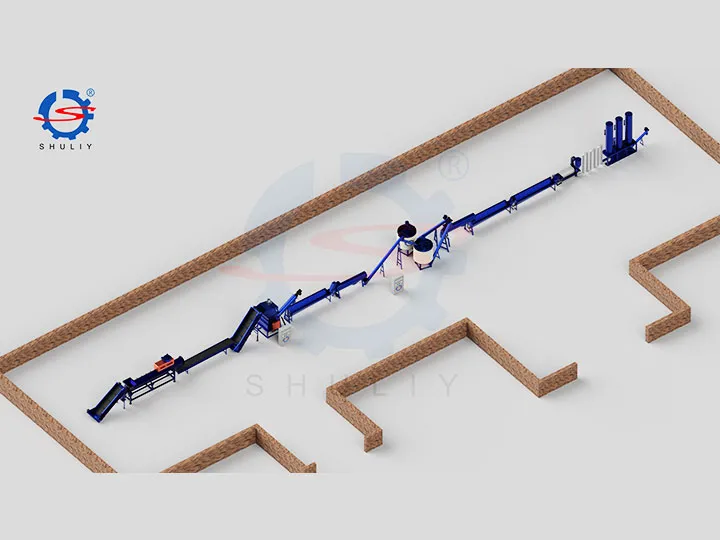

Taking the placement of “I” shaped equipment as an example, the factory covers an area of approximately 60 meters in length, 2.8 meters in width, and 4 meters in height. 6-8 manual workers are required. Below are the detailed parameters of the key PET bottle recycling machine.

| غرض | Specifications | الكمية |

| مزيل ملصقات زجاجة PET | Voltage: 380V, 50HZ, 3-phase electric Power: 15+3+1.5kw Barrel length: 4.3m, diameter: 0.63m Round bottle off-label rate 98% PVC content/(mg/kg) ≤ 100-300 (mg/kg) | 1 |

| كسارة زجاجة PET | Voltage: 380V, 50HZ, 3-phase electric Power: 37+1.5KW+1.5kw Tool: 9Crsi Production: 1000KG/H Screen size: 18mm Knife plate thickness: 40mm | 1 |

| Sink float separation tank | Voltage: 380V, 50HZ, 3-phase electric Power: 3KW سمك الجدار الخارجي: 4 ملم سمك الشفرة: 6 ملم Equipment size: 5000 * 1000 * 1000mm Control polyolefin content ≤ 200-300 (mg/kg) | 3 |

| PET flakes hot washing machine | Voltage: 380V, 50HZ, 3-phase electric Motor 4kw Electromagnetic heating power: 80KW Height: 2000mm, diameter: 1300mm | 2 |

| Friction washer machine | Voltage: 380V, 50HZ, 3-phase electric Power: 7.5KW Barrel length: 3000mm, diameter: 400mm سمك الشفرة: 6 ملم | 2 |

| PET flakes dryer machine | Voltage: 380V, 50HZ, 3-phase electric Power: 15KW Remove moisture and achieve a drying degree of around 95-98% | 1 |

Wherein the drying duct can control the moisture to less than or equal to 0.5-1%. The wind separator is used to remove the residual fine trademarks and dust, it can control the impurity content ≤ 300-500mg/kg and powder content ≤ 2000-3000mg/kg.

These two machines are suitable for production scenarios with larger outputs or higher requirements for the final products.

Global Cases of PET Bottle Recycling Line

تم شحن مصنع إعادة تدوير زجاجات PET بنجاح إلى موزمبيق

Shuliy has successfully concluded a deal with an important customer in Mozambique. This customer from Mozambique is engaged in the plastic recycling business and has ordered a 1000kg/h PET washing plant. After the machine arrived, they also took feedback pictures of us, expressing their satisfaction with our equipment and service. Below are some shipping pictures.

Plastic Bottle Washing Plant Installed in Nigeria

A customer in Nigeria customized the plastic bottle recycling machine and plastic pelletizing equipment from Shuliy to process local waste.

Shuliy’s technical team traveled to Nigeria to install and commission a plastic bottle recycling machine for a Nigerian customer to process local waste, providing not only professional technical support but also a series of customized adjustments according to the customer’s actual needs, to ensure that the equipment can meet the customer’s production requirements to the maximum extent possible.

Our PET Bottle Recycling Machine Service

Our company not only provides an efficient PET bottle recycling line but also provides comprehensive services to customers to ensure that you achieve the best results in the recycling and reuse process. Here are the services we provide for you:

Customized plan: Based on your specific needs, we will tailor a PET bottle washing line plan to ensure that the equipment configuration, production capacity, and process flow best meet your production requirements.

Make an appointment to visit our factory: You can make an appointment to visit our factory and witness our production strength and equipment quality firsthand. We will arrange for professionals to explain the working principle and advantages of the equipment to you, and answer all your questions.

On-site installation assistance: We provide on-site installation services, with an experienced technical team visiting your factory to ensure that the equipment is installed and debugged properly, helping you quickly start production.

خدمة ما بعد البيع: We promise to provide you with long-term after-sales service, including equipment maintenance, technical support, and component supply. No matter what problems you encounter during use, our after-sales team will respond promptly.

ماكينة إعادة التدوير لغسيل زجاجات PET

Plastic Bottle Recycle Machine Price

هل أنت فضولي حول كيفية المعالجة بلاستيك PET? And how much do PET bottle recycling lines cost? Usually, the PET recycling line price will vary according to the machine model, processing capacity, and production efficiency. If you are interested in the plastic bottle recycling machine or want to know the price information, please feel free to contact us, we will be happy to provide you with a detailed inquiry service to meet your needs.

The Necessity of PET Bottle Recycling Line

تبلغ الكمية السنوية للنفايات البلاستيكية في الصين حوالي 5 ملايين طن، ويتميز البلاستيك بمقاومته للتآكل، وليس من السهل تحلله، وتهطل النفايات البلاستيكية لفترة طويلة، وستدخل المواد المضافة السامة في البلاستيك إلى المياه الجوفية والأنهار والبحيرات. الناجمة عن التلوث، مما يعرض صحة الإنسان للخطر!

Therefore, waste plastic has caused a lot of potential harm to the environment and has become an environmental issue of concern to all sectors of society in China. This characteristic and its small weight and large volume in the garbage determines that its final disposal is not suitable for landfill.

However, it is a macromolecular material with high calorific value, recycling is in line with the basic national policy of sustainable development in China, and can also make full use of its intrinsic value, save resources, and protect the environment.

Significance of PET Bottle Recycling Line

Protect The Environment

يمكن أن يؤدي التخلص غير السليم من النفايات البلاستيكية إلى تلوث البيئة وتدهور البيئة البيئية المحلية. من خلال خط إعادة تدوير زجاجات PET، يمكننا تقليل تأثيرها على البيئة، ومنع التلوث، وحماية البيئة البيئية.

Saving Resources

يستهلك إنتاج البلاستيك الكثير من الموارد مثل دور PET، ويمكن لإعادة تدوير نفايات البلاستيك إعادة استخدام هذه الموارد بدقة وتحقيق غرض التوفير. في عملية معالجة النفايات البلاستيكية، يمكن إعادة تدوير البلاستيك وإعادة معالجته لصنع منتجات بلاستيكية جديدة، وبالتالي تحقيق غرض توفير الموارد.

Cost Reduction

بالمقارنة مع إنتاج المواد البلاستيكية الجديدة، فإن إعادة تدوير النفايات البلاستيكية أقل تكلفة. وفي الوقت نفسه، يمكن لإعادة تدوير النفايات البلاستيكية أن تجلب إيرادات إضافية لشركات التصنيع.

Prospect of Plastic Bottle Recycling Machine

في الوقت الحالي، أصبحت إعادة تدوير النفايات البلاستيكية مهمة بالغة الأهمية في جميع أنحاء العالم. استثمرت الحكومات والشركات الكثير من الموارد البشرية والمادية لتعزيز تطوير إعادة تدوير النفايات البلاستيكية.

وفي الصين، تتطور صناعة إعادة تدوير النفايات البلاستيكية بسرعة أيضًا. وقد أدخلت الحكومة سلسلة من السياسات والتدابير لدعم إعادة تدوير النفايات البلاستيكية، والتي يمكن أن تعزز أيضًا تطوير حماية البيئة.

في الوقت نفسه، استثمرت الشركات المحلية بنشاط في صناعة إعادة التدوير لتعزيز مفهوم إعادة استخدام نفايات البلاستيك، وتشكيل حجم صناعة إعادة تدوير النفايات البلاستيكية، كما أن إعادة تدوير الخردة البلاستيكية تجلب المزيد من الموارد للمؤسسات. لذلك، يتمتع سوق خطوط إعادة تدوير زجاجات PET بآفاق واسعة ومستقبل واعد.