The horizontal dryer is an efficient plastic drying equipment designed for dewatering and drying plastic sheets. The main function of the machine is to remove the water from the cleaned plastic sheet quickly, and the dryness can reach 95%-98%.

The plastic dewatering machine adopts the principle of centrifugal force to efficiently remove water from the surface and inside of the plastic to ensure the smoothness of the subsequent processing procedures. This kind of equipment is widely used in plastic bottle recycling plants and the washing line of PVC, HDPE, and other hard plastics, which is an important tool to improve the efficiency and quality of plastic recycling.

Principle of Horizontal Dryer

Horizontal dryer mainly utilizes centrifugal force to realize the dehydration and drying of plastic sheets. After entering the dryer, the plastic sheet is thrown to the cylinder wall by the high-speed rotating drying cylinder. Due to the effect of centrifugal force, the water is thrown out quickly, and the water in the plastic sheet is removed efficiently.

Application of Plastic Chips Dryer Machine

Horizontal plastic dryer machine is widely used, especially in the washing line of PET, PP, PE, PVC, and other sheet materials play an important role. This equipment can efficiently shake out the moisture of plastic sheets to 95%-98%, ensuring the dryness of the material when it enters the next processing stage.

For customers who require a higher degree of dryness, we also offer advanced drying ducts, which are manufactured in 304 stainless steel and are capable of further controlling moisture to 0.5%-1%.

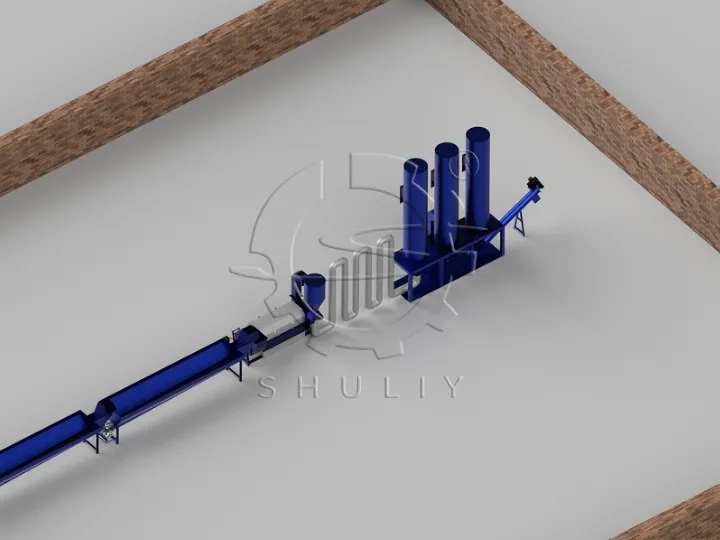

In addition, the horizontal dryer can also be used in conjunction with the vertical dryer to form a more complete drying system and achieve better dewatering results. This flexible combination not only improves the drying efficiency but also can be customized according to the specific needs of customers to provide a more optimized solution.

Plastic Dehumidifying Dryer Parameters

The performance parameters of the plastic flake dewatering machine are an important guarantee for its efficient operation. The following are some key parameters of this equipment:

| Drying rate | 95%-98% |

| Processing capacity | Up to 1000kg/h |

| Power | 15kw |

| Voltage | 380V,50HZ,3 phase power |

| Outer wall thickness | 4mm |

| Blade thickness | 10mm |

| Scope of application | Widely used in PET, PVC, PP, PE |

| Drying pipes | Drying rate:0.5%-1% Material: 304 stainless steel |

Shuliy also offers a wide range of other models and sizes of horizontal dryers that can be customized to meet specific customer needs. Whether it’s for different sizes of production or specific plastic materials, we can provide the appropriate solution to meet the plastic recycling needs of our customers. Feel free to contact us and we will be happy to provide you with customized services.

Horizontal Dewatering Machine Features

- High-efficiency drying: The machine can dry the water of plastic sheets to 95%-98%.

- Drying pipe: For customers who need higher dryness, it is equipped with a drying pipe made of 304 stainless steel, which can control moisture at 0.5%-1%.

- Safety design: our horizontal dryer is equipped with a cyclone discharge device, which effectively decelerates the speed, prevents the spilled materials from harming the workers, and guarantees production safety.

- Wide application: The plastic dewatering machine is widely used in the cleaning line of PET, PP, PE, and PVC sheets, which can meet the drying needs of different customers.

- Strong customizability: the equipment design is flexible and can be adjusted and customized according to the specific needs of customers to achieve the best use.

Plastic Chips Dryer Machine Exported to Indonesia

A customer from Indonesia needed a set of equipment to wash and dry 1cm-sized pieces of plastic film. To meet the customer’s needs, we specially customized the screen size of the horizontal dryer to prevent material leakage.

At the same time, the customer has high requirements for the drying rate and wants the moisture content of the dewatered material to be less than 0.5%. Therefore, we have equipped the machine with a highly efficient drying pipe to ensure high quality and low moisture content of the final product to meet the customer’s strict requirements. The following is the picture of the horizontal dryer shipped to Indonesia.

Contact Us Now And You Can Get

Product consultation and introduction: detailed understanding of customer needs, to provide appropriate product solutions and introduction, including equipment models, output, and specific applications.

Customized solutions: Provide customized equipment and production line solutions according to the customer’s special needs and actual situation to ensure that the customer’s production requirements are met.

Visit our factory: we welcome customers to visit our factory and inspect the equipment on site. If you can’t come, we can also have a video tour of the factory.

Quotation and contract signing: According to the customer’s needs and customized solutions, provide detailed quotations, and sign a formal contract after reaching an intention to cooperate.

Equipment manufacturing and delivery: Manufacture equipment according to the contract requirements, strictly control the quality, and arrange logistics to deliver the equipment to the customer’s designated location safely and on time.

Installation and commissioning: Send professional technicians to the customer site for equipment installation and commissioning.

After-sales service and technical support: provide long-term after-sales service, including equipment maintenance, parts replacement, and technical support, to ensure the stable operation of the equipment in the process of use.