Shuliy Machinery-A Provider of Solutions Specialising in Resource Regeneration and Environmental Machinery

We provide efficient and reliable solid waste recycling solutions to a global clientele. With years of focus on recycling technology for plastics, tires, metals, and fibers, we offer everything from core equipment to comprehensive systems. Our expertise turns your waste into valuable raw materials, boosting your profitability while protecting the environment. We aim to be your most trusted long-gterm partner.

One-Stop Recycling Production Line Solutions for Efficient Automated Production

We deliver fully integrated, automated production lines customized for your materials and output goals. Our expertise spans diverse applications, from Plastic Film and Hard Plastic Pelletizing to specialized PET Bottle Washing and Foam Recycling. We also offer advanced Rubber Powder Lines for tires and sustainable Egg Tray Production Lines. Each system is engineered for reliability, energy efficiency, and superior final product quality, empowering your recycling venture.

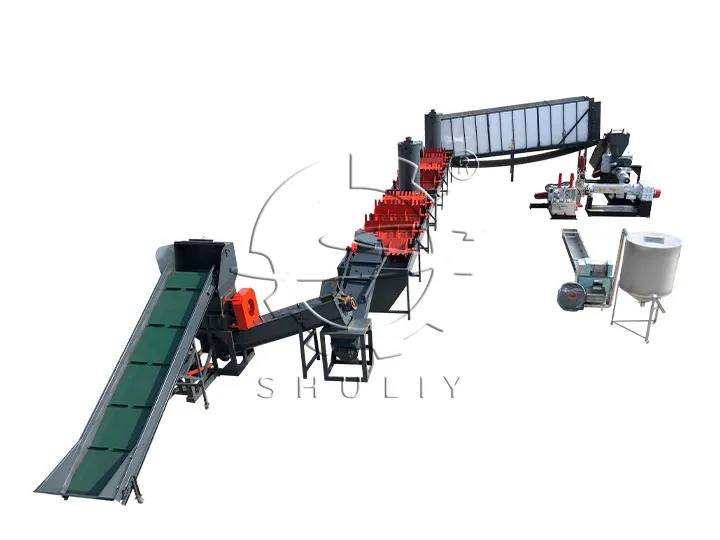

This production line integrates crushing, washing, dewatering, and extrusion pelletizing processes. It efficiently transforms bulky, lightweight waste films into recycled plastic pellets, providing high-quality raw material for downstream applications such as film blowing and injection molding.

- Raw Materials: Waste PE/PP films, agricultural films, packaging bags, jumbo bags (FIBCs), non-woven fabrics, etc.

- Final Product: High-quality recycled PE/PP pellets.

- Main plastic pelletizing machines: plastic film crusher, plastic washing machine, centrifugal dewatering machine, pelletizing machine, pellet cutter, etc.

- Output: 100-500kg/h

- Finished Product Quality: Uniform and solid pellets with excellent plasticization, free of air bubbles, and high density.

This solution focuses on transforming various rigid plastic wastes—such as pipes, HDPE bottles, appliance casings, and industrial scraps—into high-performance recycled pellets for wide use in injection molding, extrusion, and other fields.

- Input Materials: HDPE pipes & bottles, ABS/PS casings from electronics, PC water jugs, PVC profiles, PP crates, and other rigid plastics.

- Output Product: High-quality recycled pellets (HDPE, PP, ABS, PS, PC).

- Core Equipment: Rigid plastic crusher, rinsing tank, centrifugal dewatering machine, plastic extruder, pellet cutter machine, storage silo.

- Output: 100-500kg/h

- Finished Product Quality:Uniform pellet size, good fluidity, stable physical properties, and suitable for direct use in re-production.

This production line processes post-consumer PET bottles, transforming them into pure PET flakes through crushing, separation, and drying. The flakes are suitable for producing polyester staple fiber, packaging straps, and even new bottles (bottle-to-bottle grade).

- Raw Materials: Baled or loose post-consumer PET bottles, mixed-color bottles.

- Final Product: High-purity PET flakes.

- Core Equipment: Bale opener, label remover, PET bottle crusher, sink-float separation tank, hot washer machine, friction washing machine, dewatering machine, and hot air drying system.

- Capacity Range: 500 - 6000 kg/h (customizable).

- Finished Product Quality:High purity flakes with PVC content below 100 PPM, low impurity levels, and moisture content under 1%.

We offer a complete foam recycling solution that compacts bulky EPS, XPS, and EPE by up to 90:1. This process dramatically cuts storage and transport costs. Additionally, we provide pelletizing equipment to recycle various foam waste materials into reclaimed pellets.

- Raw Materials: EPS packaging foam, XPS insulation boards, EPE foam, food containers, etc.

- Final Product: High-density cold-pressed blocks, hot-melted ingots, or recycled pellets.

- Main plastic pelletizing machines: foam crusher, foam compactor, styrofoam melting machine, cooling tank, foam granulator, and pellet cutter.

- Output: 100 - 300 kg/h

- Finished Product Quality: High compression yields dense blocks that are easy to transport and sell. The recycled pellets can be used to make picture frames, moldings, and construction materials.

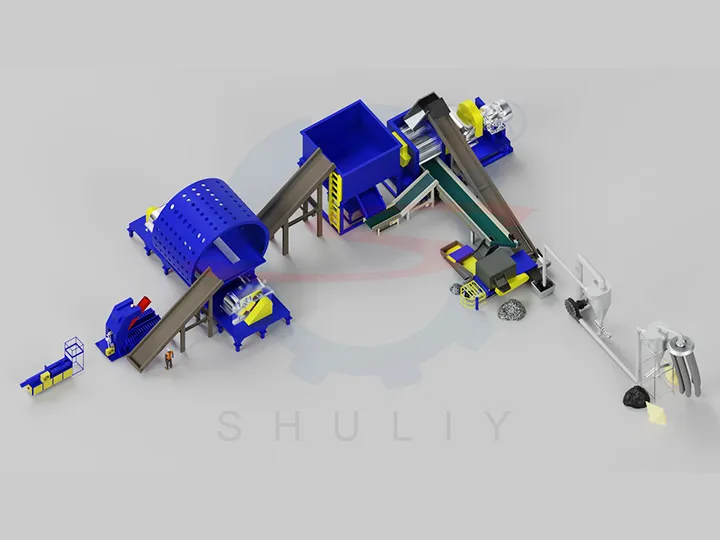

This production line systematically breaks down whole tires, ultimately producing high-purity, fine rubber powder while automatically separating steel wire and fiber.

- Input Materials: Scrap passenger car tires (PCR), truck tires (TBR), and OTR (Off-the-Road) tires.

- Output Product: Rubber powder or granules (10-40 mesh, adjustable), steel wire, and fiber.

- Core Equipment: Tire sidewall cutter, tire strip cutter, tire block cutter, steel wire separator, tire debeader, tire cutter machine, tire dismantling machine, tire shredder, rubber crusher, fiber separator

- Capacity Range: 80 - 2300 kg/h.

- Finished Product Quality:The rubber powder is of high purity, free from steel and fiber contaminants, and has a uniform mesh size. It is ideal for producing reclaimed rubber, waterproof membranes, modified asphalt, and other rubber products.

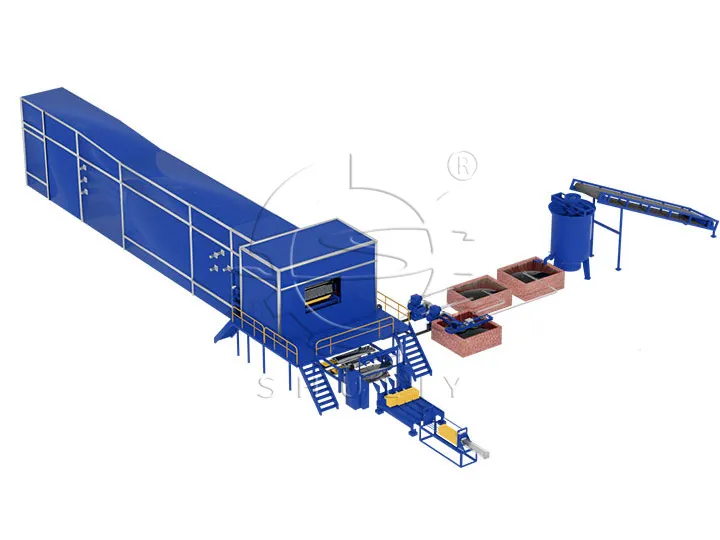

Our egg tray manufacturing plant

utilizes waste paper as its raw material, manufacturing a variety of pulp molded products through an automated process of pulping, forming, drying, and hot-pressing.

- Input Materials: Various types of waste paper, including cardboard, newspapers, books, etc.

- Final Product: Egg trays, fruit trays, shoe inserts, seedling cups, industrial packaging, and other pulp molded items.

- Core Equipment: Hydraulic pulper, pulp pool, pulp pump, egg tray forming machine, traditional brick kiln drying line / multi-layer metal drying line, hot press machine, and packing machine.

- Output: 1000 - 8000 pieces/hour (customizable).

- Finished Product Quality:The final products have a uniform shape, good strength, a smooth surface, and are evenly dried.

Machines for Every Material Processing Need

We offer a comprehensive range of robust and reliable standalone machines. Our equipment covers diverse recycling sectors—including plastics, tires, paper pulp, fibers, and metals—to meet your specific processing needs.

We offer a comprehensive range of robust, stand-alone recycling equipment that can either supplement your existing production lines or be deployed for specific processing stages. Our product portfolio spans five key recycling sectors:

Offers specialized scrap crushers for different materials such as plastic films, rigid plastics, and EPS foam.

Configured with targeted washing machines, and dewatering machines based on material properties.

Provides customized plastic pelletizing solutions for PE/PP films, rigid plastics, and EPS/EPE foam.

Includes high-efficiency label removers, specialized PET crushers, and a complete cold and hot washing system.

Includes equipment for sidewall cutting, strip cutting, and block cutting to break down whole tires for further processing.

Offers tire debeaders and wire separators to extract bead wire, with models available for everything from car tires to OTR tires.

Utilizes a dual-shaft shear design to powerfully shred pre-processed tire pieces or whole tires into 50-100mm rubber blocks.

Integrates grinding, screening, and magnetic separation to finely mill rubber blocks into high-purity rubber powder of 10-40 mesh.

Utilizes a hydraulic pulper to efficiently break down various waste papers into a uniform pulp mixture.

Offers various forming machine models with a wide capacity range from 1000 to 8000 pieces/hour to meet different production scales.

Provides multiple drying options, including natural sun-drying, traditional brick kiln drying, and a fully automatic multi-layer metal drying line.

Optional automatic stackers and packers are available for automatic counting, stacking, and compressing of finished egg trays.

Capable of quickly cutting waste fabrics, yarns, fishing nets, and chemical fiber filaments into short pieces of a set length.

Used to open, card, and clean the cut fabric pieces or fiber waste to produce recycled cotton or regenerated fibers.

Utilizes hydraulic power to cold-press various light and thin metal scraps (like scrap iron, aluminum, and copper) into high-density bales.

The scrap metal shear is suitable for heavy-duty shearing of large and heavy scrap steel and metal structural parts for easier transport and smelting.

Employs a dual-shaft shearing principle to shred bulky metal waste such as car shells, paint drums, and scrap appliances into smaller pieces.

Recycling Solutions & Applications

Here we share success stories, project experiences, and product applications from customers around the world. From egg tray production lines to plastic, metal, and paper recycling equipment, this blog offers customer stories, machine operation tips, and the latest technology updates. Discover how our machines deliver efficient and reliable performance in various recycling projects worldwide.