Our PP PE flake recycling line is a production facility designed to process and recycle a wide range of rigid plastics, converting waste plastics into reusable plastic pellets through a series of process steps.

The line is suitable for processing rigid plastics such as ABS, PS, PP, PE, PVC, etc., with a wide range of outputs, usually between 100kg/h and 500kg/h, which can be customized according to customers’ specific needs. Equipment configurations vary for different outputs to ensure optimum productivity and economic efficiency.

Below is the video of the plastic recycling machine running, so you can have a general understanding. In the article, we will introduce the details of the machine, production process, and customer cases for you.

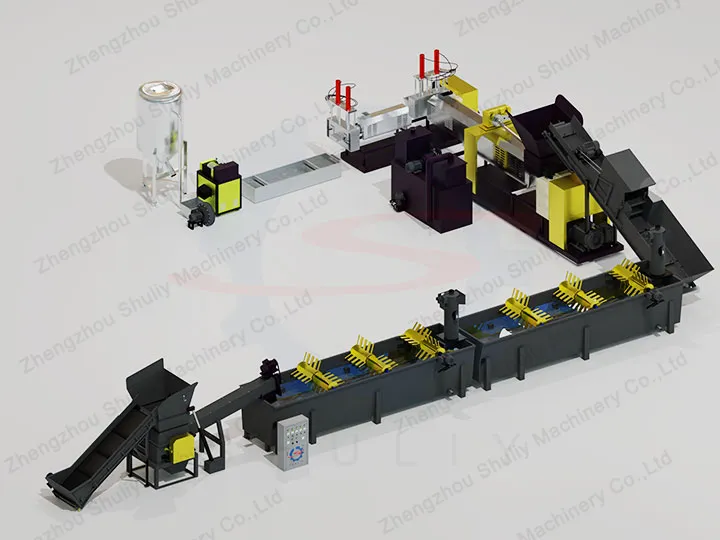

Configuration of Plastic Scrap Recycling Machine

Let’s first understand the device configuration of the PP PE flake recycling line, which is a concern for many customers. The line is a flexible and versatile production equipment system, which can be flexibly configured according to the specific production needs of customers to meet different production requirements and objectives.

Complete Plastic Pelletizing Line

It is suitable for customers who need the whole process from crushing and washing to pelletizing. The solution includes the crushing part, cleaning part, and granulating part, which can realize a one-stop plastic recycling processing service.

Partial Washing Only

For customers who only need cleaning services. This solution only includes equipment for the cleaning part, such as waste plastic crushers, plastic rinsing tanks, friction washers, hot washers, and plastic dewatering machines. Suitable for customers who already have the pelletizing machine but need pre-treatment for crushing and cleaning.

Pelletizing Section Only

For customers who only need pelletizing services. The solution includes only the equipment for the pelletizing part, such as the plastic recycling extruder machine, the cooling tank, and the plastic granule cutter. It is suitable for customers who already have crushing and washing equipment, but need further processing into pellets.

Our Personalization Service

To meet the different needs of customers, we provide personalized customization service, which can tailor the most suitable production configuration and program according to the customer’s production scale, raw material type, output requirements, and other factors, to ensure that each customer can obtain the best production results and economic benefits.

Our PP PE flake recycling lines are widely used in all kinds of plastic recycling enterprises due to their flexible and versatile configurations and efficient and environmentally friendly production advantages. If you are looking for a suitable solution, you can leave a message on our website, our professional sales manager will communicate with you in detail to confirm the production capacity, discuss the program, and send a quotation.

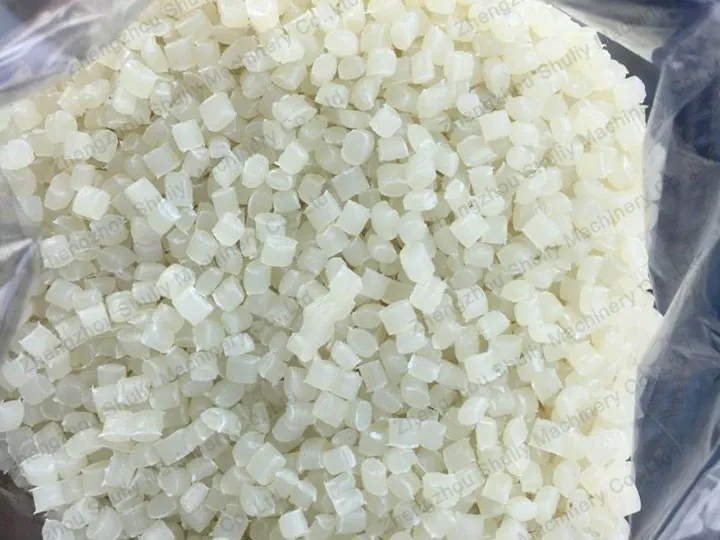

Raw Materials And Finished Products

Next, we will list some raw materials for this PP PE flake recycling line for your reference. If you have already collected the raw materials, but you are not sure about the type of raw materials and what kind of equipment to choose, we can also help you to judge and give you reasonable suggestions.

Our rigid plastic pelletizing lines are designed to process a wide range of rigid plastics for a wide range of applications including, but not limited to, HDPE bottles, plastic containers, plastic sheets, electrical appliance housings, and PVC containers. After being processed by our equipment, these raw materials can be efficiently crushed, cleaned, dewatered, and pelletized to be regenerated into high-quality plastic pellets.

Plastic Granulation Production Process

The production process of plastic pelletizing has a profound impact on its quality and cost and is critical to ensuring uniform and consistent pellets. Precise control of melt temperature, extrusion pressure, and cutting speed on our equipment ensures that pellet size, shape, and properties are in line with requirements, improving product consistency and reliability. Below you will find a detailed description of the plastic pelletizing process.

- Crushing: Waste plastics are crushed into small pieces in a waste plastic crushing machine.

- Washing: The crushed plastic pieces enter the cleaning equipment and are thoroughly cleaned. This process removes dirt, grease, and other impurities from the plastic and ensures the purity of the recycled pellets.

- Dewatering: The washed plastic pieces are dewatered through a dewatering machine to remove excess water and prepare them for the subsequent pelletizing step.

- Pelletizing: Dewatered plastic chips are fed into a plastic granules making machine to be melted and extruded to form a continuous strip of plastic.

- Cooling and cutting: The molten plastic strip from the granulator enters the cooling pool and is cut into small, homogeneous granules using a pellet cutting machine.

3D Video of Plastic Waste Recycling Plant

Related Equipment for Plastic Granulating Line

Conveyor Belt

It is used to feed PP PE material into the plastic crusher, which is a necessary plastic recycling equipment for the plastic granulating line.

Plastic Crusher

In the plastic granulation line, the plastic shredder is used to crush waste PP PE plastic products into small pieces with low noise and no residue during the crushing process. In addition, it uses imported alloy blades with long life, strong cutting ability, and low maintenance cost. This kind of plastic crusher has been well received by customers.

Rinsing Tank

In the PP PE flake recycling line, the rinsing tank is made of stainless steel or iron plate, which is used to rinse the crushed materials to make the impurities settle and effectively remove the stains on the plastic.

Horizontal Dewatering Machine

The horizontal dewatering machine has the unique ability to remove most of the water from PP PE directly after the cleaning process. With a high dewatering rate and low power consumption, this plastic drying machine is ideal for plastic granulating lines.

Plastic Pelletizing Machine

The plastic granulator is the core equipment in the PP PE flake recycling line.

The machine can accurately control the melting temperature, extrusion pressure, and cutting speed, with high stability and reliable operation, ensuring stable production for a long time.

Plastic Granule Cutter

The plastic granule cutter can cut granules from plastic drawing feed, suitable for granulating and cutting granules after pulling strips. Cutting size and speed can be adjusted as required.

Storage Bin

It is suitable for the storage of plastic pellets, convenient for packaging, and labor-saving. The size is optional and customized according to the customer’s requirements.

Technical Characteristics of Plastic Recycling Plant

- The whole plastic recycling plant is controlled automatically, with a compact process, high production efficiency, and strong granulation capacity.

- The plastic recycling equipment can easily separate the impurities such as mud and sand in the plastic flakes; the treatment system equipped can greatly improve the quality of the finished products.

- PP PE flake recycling line is easy to maintain, has low energy consumption, and long service life. One of our customers gave us feedback some time ago that the equipment he purchased years ago is still in use and running well.

plastic granulating line

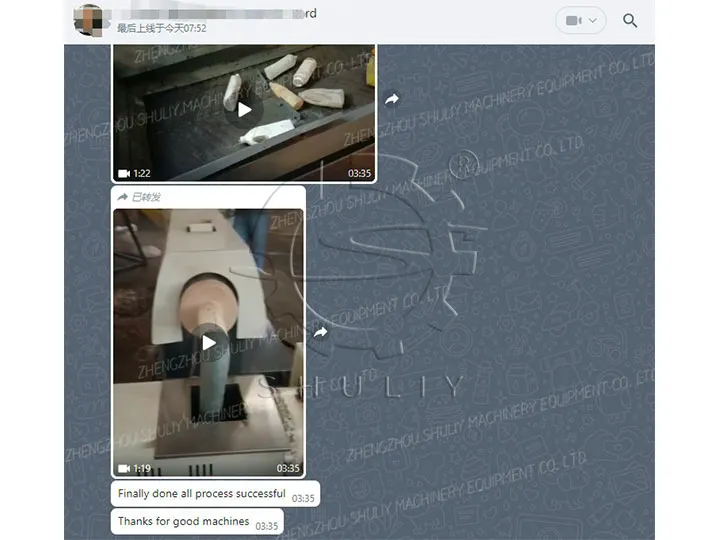

Successful Plastic Pelletizing Line Transaction Case

HDPE Recycling Machine Exported To Côte d’Ivoire

This customer from Côte d’Ivoire is looking for plastic recycling machines that process HDPE bottles into plastic pellets. After detailed communication with us, the cooperation was finally reached. We have successfully shipped the HDPE recycling machine to Cote d’Ivoire. The customer gave us good feedback after running the machine, saying that the machine is running well.

Plastic Recycling Granulating Line to Botswana

The plastic recycling granulating line shipped to Botswana was customized according to the customer’s requirements. From the customer’s inquiry to the discussion of the proposal, sending the quotation, and reaching cooperation, we gave the customer a good experience throughout the whole process, which was also acknowledged by the customer. Below is the picture of the machine delivery.

Advanced PP PE Flake Recycling Line Manufacturer

With more than 15 years of experience in plastic recycling, Shuliy Machinery has proven insight into the PP PE flake recycling line. Our pelletizer machine plastics and other products have been exported to many countries and regions and have won a good reputation from our customers.

We support customized plastic recycling pelletizing machines according to the characteristics of the material. If you also want to start a plastic recycling business or upgrade your existing plastic recycling process equipment, feel free to contact Shuliy’s staff for customized solutions.

Inquiry About Plastic Recycling Equipment Price!

Do you want to know how to recycle PP PE plastic? Please contact us! We specialize in providing high-quality PP PE flake recycling lines, which offer reliable solutions for your production. Feel free to contact us for more information and a quote, and we look forward to customizing a plastic pelletizing line that best suits your needs.