Plastic crushing machine is widely used for crushing waste plastics and recycling of plastic trimmings in factories. It can shred various waste plastics such as woven bags, films, food packaging bags, plastic baskets, plastic buckets, etc. The crushed plastic flakes can be further cleaned and pelletized.

As a plastic scrap shredder manufacturer, we are committed to providing high-quality plastic crushing equipment to customers all over the world. Our plastic recycling crushers come in a variety of styles and models to meet the various production needs of our customers.

Below is a video of the plastic crusher working, which shows the good performance of our equipment.

Introduction of Plastic Crushing Machine

The plastic crushing machine is a mechanical environmental protection recycling equipment specially made for the shredding and crushing of materials, commonly used in the plastic pelletizing line or plastic washing recycling line. Plastic crushing machines can shred polypropylene PP PE plastic products and materials, such as plastic film, plastic bags, woven bags, plastic barrels, plastic casing, HDPE bottles, plastic products trimmings, etc., to facilitate plastic recycling and recycled plastic pellets.

Shuliy Machinery’s waste plastic recycling crusher processing capacity ranges from 600-1200KG/H, which can be customized according to the customer’s requirements, you just need to let us know the size and dimensions of the waste to be processed, and we will provide you with the right plastic crusher machine.

Advantages of The Shuliy Plastic Recycling Shredder

Our plastic shredder is an efficient and durable machine designed to handle all types of waste plastics.

The plastic recycling shredder machine is equipped with powerful blades and high-performance motors to ensure efficient crushing capacity. The equipment is easy to operate and maintain and is suitable for all kinds of plastic recycling and reclamation enterprises. Its sturdy structure and durable materials enable it to operate stably for a long time in a high-intensity working environment.

In addition, our plastic crushing machines can be customized to provide different feed opening sizes, output pellet sizes, and processing capacities to meet the production needs of different customers.

Application of Waste Plastic Crusher

Next, let’s discuss what materials can be processed in a plastic crushing machine. Our plastic shredders are designed to work with a wide range of waste plastic materials including, but not limited to, plastic film, plastic bags, woven bags, HDPE bottles, plastic containers, plastic sheets, plastic packaging materials, appliance housings, and PVC containers.

Do you have a specific type of plastic scrap to process? We can recommend the most suitable machine model and configuration for your specific needs, ensuring you get the best possible shredding results.

Parameters of Waste Plastic Shredder Machine

As a professional plastic crusher machine manufacturer, Shuliy offers a wide range of crusher models. Below are some hot models of plastic waste crushers and their parameters. If you are interested, you can also directly consult with Shuliy’s sales manager to get the most suitable crushing solution for your plastic recycling factory’s needs.

| Model | SLSP-600 | SLSP-800 | SLSP-1000 |

| Motor power(kW) | 45 | 55 | 55 |

| Capacity(kg/h) | 600-800 | 800-1000 | 1000-1200 |

| Material of knives(Si2Mn) | 60 | 60 | 60 |

| Number of Knives(pcs) | 10 | 10 | 10 |

| Box width(cm) | 600 | 800 | 1000 |

Working Principle of Plastic Crusher Machine

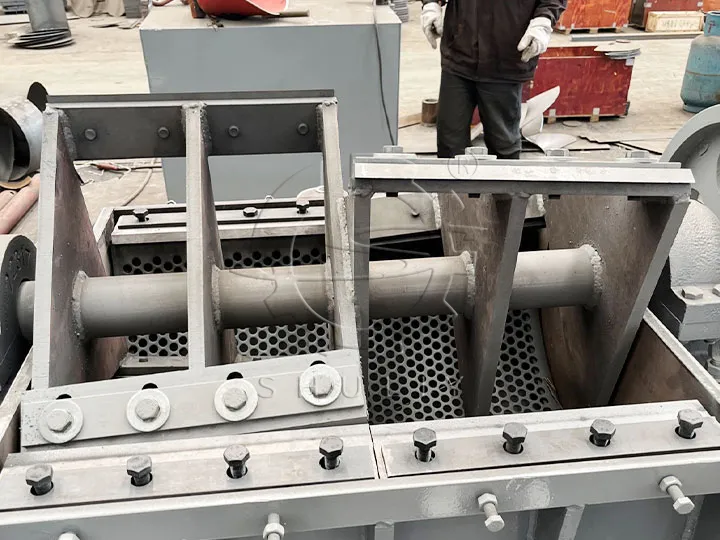

Plastic crusher machine in the working process, its motor drives the rotating blade disc high-speed rotation, high-speed rotation of the rotating blade and fixed blade with the formation of relative movement trend.

At the same time, the gap between the moving knife and the fixed knife is used to produce plastic grinding and cutting edge, thus crushing large pieces of plastic. Finally, the crushed plastic is filtered and output through the screen according to the size of the plastic particles.

It is worth mentioning that the gap between the movable knife and the fixed knife of the plastic crushing machine will be adjusted according to the different materials to be processed. For hard materials, the gap will be slightly larger, while for film materials, the gap will be relatively smaller.

Similarly, the size of the screen varies depending on the material being processed. For film materials, the screen size is usually between 40-50 mm, while for hard materials, the screen size is between 20-26 mm. We can flexibly adjust these parameters according to the actual materials handled by the customer to ensure the best pulverizing effect.

Power Mode Of Plastic Crushing Machine

According to the different needs of customers, we mainly provide two kinds of power methods: electric motor and diesel engine.

The motor-driven shredder is suitable for stable industrial environments and recycling scenarios with a reliable power supply. It is characterized by stable operation, easy maintenance, and simple operation, and is particularly suitable for large-scale, highly continuous plastic recycling processing plants.

The diesel-powered shredder, on the other hand, is suitable for recycling scenarios where the electricity supply is unstable or where it is not possible to connect to a power source. It has the advantages of an autonomous power supply and high flexibility, which makes it particularly suitable for outdoor operations or small recycling enterprises and temporary recycling sites in remote areas. This type of power is slightly more complicated to maintain but has obvious advantages in terms of mobility and independence.

Video of Waste Plastic Shredder Machine

Characteristics of Plastic Shredder

- The plastic crusher blade is forged from 60Si2Mn material, with a thick blade body, strong crushing force, strong cutting ability, and high output.

- The body of the waste plastic shredder machine is welded with a high-strength steel plate, which can withstand high torque, is extremely sturdy and durable, and has a long service life.

- Our plastic crusher can choose to add a fan when processing film material, this is because the film material is relatively light, and adding a fan can better extract the material. You can also choose to add water to the machine for wet crushing, which does not require a fan.

- Plastic crushing machines can be customized to meet specific customer requirements. Whether you have special needs for appearance, specifications, or the type of plastic to be processed, Shuliy has the solution.

Plastic Recycling Shredder Export Case

SL-800 Waste Plastic Crusher Exported To Somalia

This customer from Somalia ordered our SL-800 plastic crushing machine, which has a capacity of 700-800kg/h, equipped with a 35hp diesel engine. To ensure the performance of the machine, the customer personally came to our factory site for inspection, we on-site tested the machine for the customer, and the customer was very satisfied with the crushing effect.

SL-400 Plastic Recycling Crusher Sent to Nigeria

Recently, we customized an SL-400 plastic crusher for a Nigerian customer, the output of the machine is 400-600kg/h, the power is 11KW, and the blade material is 55Crsi. the customer asked for wheels on the machine for the convenience of moving around, we customized the machine according to the customer’s request. Here are the pictures of the machine.

Maintenance of Plastic Shredder Machine

- The plastic shredder machine should be kept well grounded, and placed in a ventilated position to ensure that the heat of the motor work is distributed to prolong its life.

- The bearings should be filled with lubricant regularly to ensure the lubrication between the bearings.

- To ensure the sharpness of the cutting edge of the plastic crusher machine blade, the knife should be checked frequently to ensure its sharpness and reduce unnecessary damage to other parts caused by the dullness of the knife.

- Check regularly whether the plastic crusher belt is slack, and adjust the tightness in time.

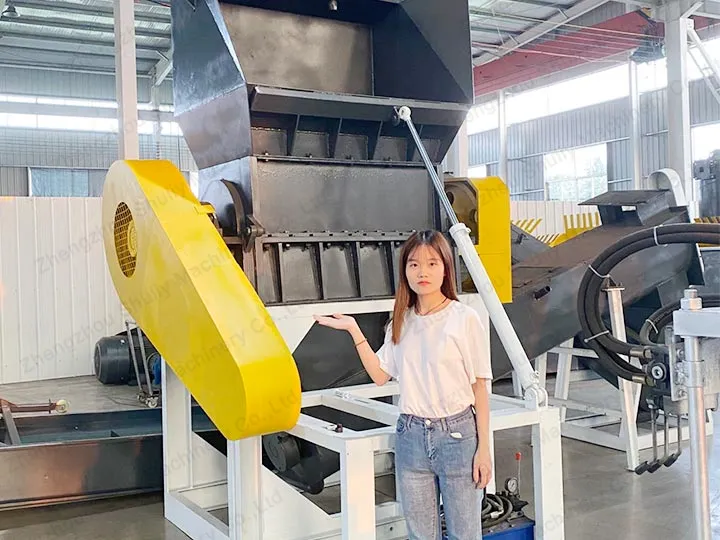

Field Trip To The Plastic Crushing Machine Factory

As a plastic crusher machine manufacturer with more than ten years of experience in plastic recycling, Shuliy welcomes all customers to visit our factory to show them our real production and processing capability.

We always believe that a site visit is important when buying a plastic crushing machine. You are welcome to visit our factory to see the real machine, or even to operate the plastic crushing machine yourself!

If you are interested in plastic recycling pelletizing, please feel free to contact us or leave a message on our website. Our professional staff will recommend the most suitable machine for you.

Plastic Waste Shredder Machine Price

As a professional plastic waste shredder machine supplier, we offer a wide range of plastic crushers in various sizes and capacities, with prices varying according to models and features. If you have any questions about the plastic crushing machine, please feel free to contact us, we will be happy to provide you with the most suitable solution.