Our plastic pellet making machine is an efficient machine designed for recycling and reclaiming waste plastics. The machine is capable of processing various types of waste plastics, such as plastic films, rigid plastics, plastic containers, etc., into high-quality plastic pellets.

Through advanced heating and extrusion technologies, the plastic pellet extruder machine enables efficient plastic melting and pelletizing, ensuring the purity and uniformity of the finished pellets.

The easy operation of the equipment, low maintenance costs, and low energy consumption make it ideal for plastics recycling companies. We offer a wide range of models and configurations to meet the needs of different customers and can be customized to meet specific customer requirements.

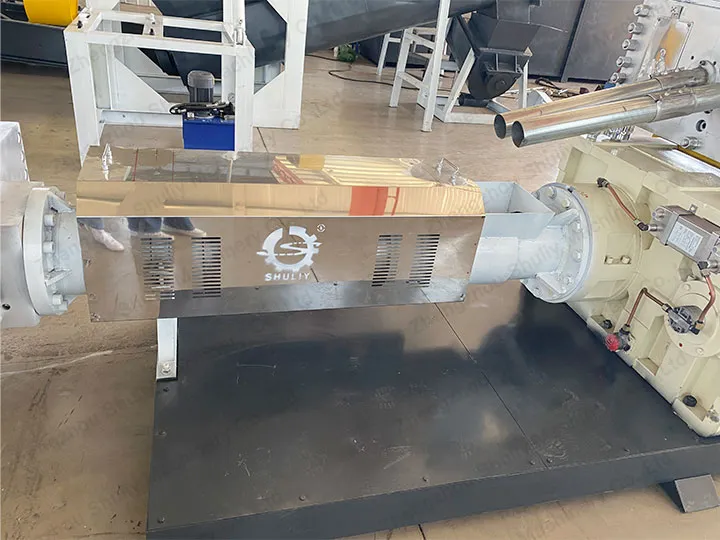

Shuliy Plastic Pellet Making Machine

As the most widely used and popular plastic recycling machinery in the waste plastic recycling industry, the plastic recycling pellet machine can create significant economic benefits and optimize the allocation of resources. Here we will take you to know more about our plastic pelletizing equipment.

With a wide range of production capacity, Shuliy plastic pelletizer can provide production capacity ranging from 100kg/h to 500kg/h according to customer’s demand, which can meet the needs of different scales of production.

We offer a full range of customization services, where you can customize the appearance, configuration, and output of your equipment according to your actual needs. Regardless of your plant layout, we can design the most suitable production line direction for you to ensure the best configuration and efficient operation of the equipment.

Plastic Pelletizing Process

The production process of plastic pelletizing includes crushing, cleaning, drying, melting, extruding, pelletizing, and cooling of plastic waste. Shuliy plastic pelletizer is optimized in each step to ensure a smooth and efficient production process.

The plastic pelletizing machine plays a vital role in the plastic pelletizing process. In a pelletizer, plastic scrap is heated to its melting point and transformed into a molten state. This process allows the plastic material to be remolded and become the raw material for new plastic products. The melting process requires precise temperature control to ensure the melt quality of the plastic.

Plastic pelletizing recycling machines can also add various additives, such as color agents, stabilizers, antioxidants, etc., during the melting process, so that the molten plastic is fully mixed with these additives to ensure the performance and quality of the final pellets.

Raw Materials & Finished Products

After understanding the working principle of the plastic recycling granulator and the entire granulation process, we may wish to further explore the raw materials used in this machine and its finished products. In this way, we can gain a fuller understanding of the importance of this equipment in plastic recycling and reclamation.

The raw materials of plastic granulators mainly include various kinds of waste plastics, such as PP PE films, bags, woven bags, packaging films, agricultural films, shopping bags, waste plastic barrels, food containers, detergent bottles, tubes, etc.

Plastic pellet making machine produces high-quality finished plastic pellets with uniform particle size and stable physical properties, which meet international and industry standards. High-quality plastic granules not only ensure the excellent performance of downstream products but also improve their market competitiveness.

Finished plastic pellets have good economic benefits and large profit margins due to their relatively low processing costs, but the market demand is strong, especially under the impetus of environmental protection policies, the market prospects for recycled plastic pellets are broad.

Plastic Granulator Machine Design Structure

This plastic recycling granulator mainly comprises a feeding port, screw press, press chamber, heating device, discharge port, mold head, reducer, and other parts. This plastic recycling granulator is the main plastic recycling production line machine, which can handle many plastic materials.

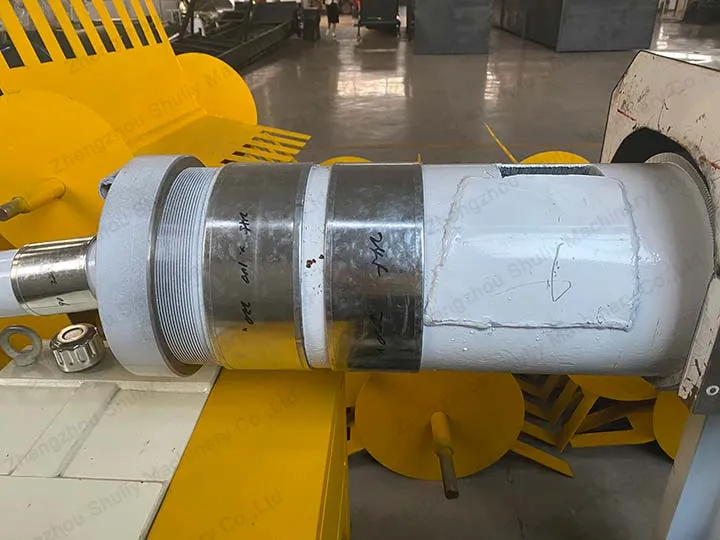

According to the different materials being pelletized, the diameter of the screw in the plastic film pelletizing machine, the distance between the screw and the barrel wall, and the length of the screw are also different. Therefore, one plastic recycling granulator cannot process many kinds of materials at the same time.

Different Mold Heads of Plastic Extruder Machine

There are three kinds of die heads for plastic extruder machines. They are electric gear die heads, screenless slag discharge die heads, and hydraulic die heads. Customers can choose the right plastic pelletizer diehead according to their needs.

Our customers choose hydraulic die heads more, hydraulic double die heads can realize non-stop screen change, more suitable for film material granulation. No net slag discharge die head is suitable for dirtier materials, and can better exclude impurities, but not suitable for raw materials containing metal, metal will block the holes on the net, and the repair cost is higher.

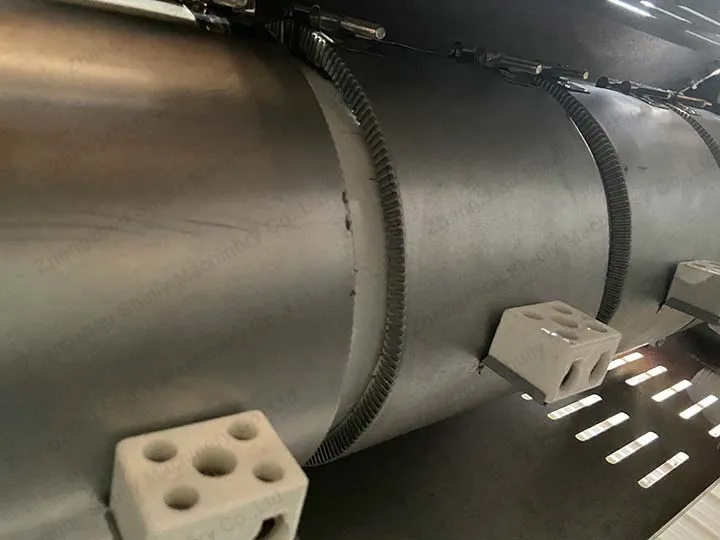

Different Heating Methods of Plastic Pellet Making Machines

The heating method of the plastic pellet making machine is the key link to ensure that the waste plastics can be melted evenly and extruded smoothly. Common heating methods include electromagnetic heating, ceramic heating, and heating rings, each of which has its own unique advantages and applicable scenarios.

Electromagnetic Heating

This type of heating is highly efficient, the heat can be quickly and evenly transferred to the plastic, and the energy consumption is low. At the same time, the electromagnetic heating system responds quickly and the temperature control is precise, which reduces the energy loss in the heating process.

Ceramic Heating

Ceramic heaters have excellent thermal stability and high-temperature resistance, providing uniform and stable heat to ensure uniform melting of plastics. Its long service life and low maintenance costs make it suitable for equipment that runs continuously for long periods.

Heater Ring

This method is simple in structure, easy to install, and suitable for general heating needs, with a wider range of applications and low-cost advantages.

Parameters of Plastic Scrap Granulator

The parameters of plastic pellet making machines include key indicators such as production capacity, screw diameter, equipment size, and weight.

These parameters directly affect the production efficiency and operating costs of the equipment, which can be customized according to the specific needs of customers to achieve the best production results and economic benefits.

We have more machine models for you to choose from, if you have any questions about the choice of machine models, you are welcome to consult us.

| Type | 125 | 135 | 150 | 180 | 210 | 220 |

| Screw diameter | 125mm | 135mm | 150mm | 180mm | 210mm | 220mm |

| Spindle speed | 50-70/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 30kw | 37kw | 37kw | 55kw | 75kw | 90kw |

| Reducer hard gear | 225 | 250 | 250 | 280 | 315 | 330 |

| Weight | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| Size | 2.6*0.7*0.7m | 2.8*0.7*0.7m | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1m | 3.8*1.2*1m |

| Output | 180KG/H | 200KG/H | 300KG/H | 350KG/H | 380KG/H | 420KG/H |

Features of Plastic Pellet Making Machine

- Multi-functional: It can be adjusted and optimized according to different plastic materials and processing requirements and is suitable for pelletizing and processing a variety of plastic raw materials.

- Strong stability: the equipment design is stable, easy to operate, and can maintain stable productivity and product quality during processing.

- Customization: Production capacity, equipment configuration, and level of automation can be tailored to the specific needs of the customer, providing a personalized solution.

- Strong durability: The main parts of the equipment are made of high-quality materials and advanced technology, which has a long service life and stable operation performance.

Successful Cases of Plastic Pellet Making Machines

Waste Plastic Extruder Shipped To Ghana

A customer from Ghana purchased the Shuliy plastic granulator machine. The model of this equipment is SL-180, and the production capacity is 350kg/h. After the production of the equipment is completed, our logistic team carefully packs and boxes the equipment for shipment. We will keep an eye on the logistics information to ensure the equipment arrives successfully.

Plastic Recycling Pelletizer Machine Installed In Nigeria

Customers from Nigeria purchased a Shuliy plastic pellet making machine and plastic bottle washing machine to recycle local waste plastics, Shuliy responded quickly to the customer’s needs and sent a technical team to Nigeria to ensure a smooth installation and commissioning of the plastic pelletizing recycling machine.

Plastic Pellet Making Machine Buying Guide

As a plastic pelletizer manufacturer, we are committed to providing our customers with a full range of services to ensure that they are satisfied with their purchasing experience and the highest quality products. Below is our service process:

Product Inquiry

Before you start to buy, you can consult our sales team through our website or contact information. Our sales representatives will introduce the technical parameters, performance characteristics, and applicable fields of each plastic granulator in detail to help customers choose the most suitable products.

Make an Appointment To See The Plant

For our customers to have more trust and understanding of our manufacturing process, we welcome them to visit our production base by appointment. Customers can personally witness our production process and equipment technology and have a more intuitive understanding of the quality of our products and manufacturing process.

Customized Solutions

We offer a personalized customization service to adjust and optimize the configuration and design of plastic pellet making machines according to the specific needs and application scenarios of our customers. Our engineering team will work closely with the customer to ensure that the customized solution perfectly matches the customer’s production needs.

Shipping And Worldwide In-home Installation

Once the customer confirms the order, we will arrange the production and shipment of the products as soon as possible. For international customers, we provide global door-to-door installation service, our technical team will be responsible for the installation and commissioning of the equipment to ensure that the equipment operates normally on the client side.