The plastic float sink tank is one of the most important washing machines in the PET bottle recycling line and its main function is to effectively separate PET bottle flakes from labels and caps. This equipment ensures the purity and quality of PET bottle flakes through the principle of float-sink separation.

During the process, PET bottle flakes will sink due to their high density, while the lighter labels and caps will float on the water surface, thus realizing effective separation. The use of this equipment significantly improves the quality of the final recycled PET bottle flakes and ensures that they are suitable for a variety of recycling applications.

Working Principle of Plastic Float Sink Tank

Using water as the medium, according to the different densities in water, the plastic float sink tank can easily achieve the separation of PET flakes and other materials and also can clean the PET flakes.

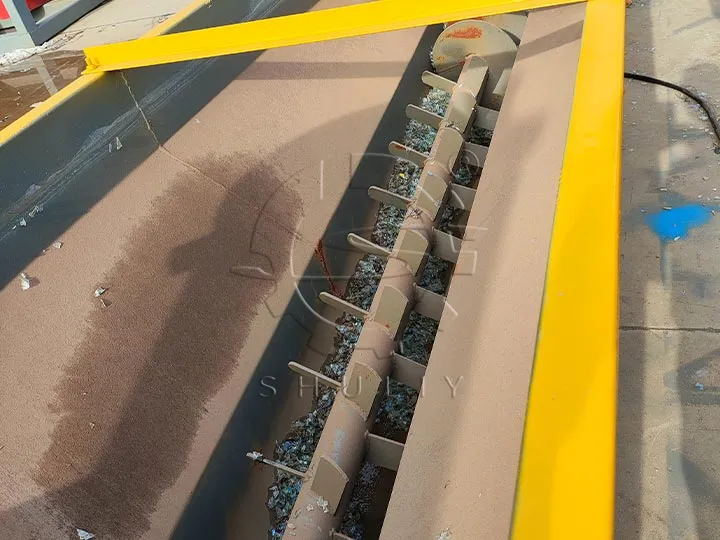

During the process, PET bottle flakes will sink due to their high density, while the lighter labels and caps will float on the water surface. The machine is equipped with a screw conveyor at the bottom of the machine to transport the sinking PET bottle flakes from the bottom of the washing tank to the next process. This design ensures that the PET flakes are effectively separated from other impurities, thus improving the purity and quality of the recycled PET flakes.

Advantages of Sink Float Plastic Separation

- Efficient Separation: Through the principle of floating and sinking separation, it can effectively separate PET bottle flakes from labels, caps, and other impurities to ensure the purity of PET bottle flakes.

- Quality Control: control polyolefin content at ≤200-300 mg/kg, significantly improving the quality of recycled PET bottle flakes.

- Automatic Conveyor: Equipped with a screw conveyor, automatically conveying PET bottle flakes to the next process.

- Flexible Adjustment: it can be flexibly adjusted according to the processing capacity and impurity content, adapting to different production needs.

Sink Float Separation Tank Parameters

Take for example the parameters of a washing tank in a 1000 kg/h washing line.

- Voltage: 380V, 50HZ, 3-phase electricity

- Power: 3KW

- Outer wall thickness: 4mm

- Blade thickness: 6mm

- Equipment size: 5000*1000*1000mm

- Control polyolefin content≤200-300(mg/kg)

Number of Sink Float Separation Tank Configurations

Normally, for PET bottle washing lines up to 1000kg/h, we recommend equipping 1 or 2 separation tanks. The first one is used for the initial separation of impurities, while the second can be installed behind the hot wash tank to clean off the lye carried out from the machine.

For PET recycling lines of 1000 kg/h and above, three plastic float sink tanks can be installed. Two separation tanks are installed behind the PET flakes hot washing machine to ensure further cleaning effect and to control the acidity of the solution during the cleaning process so that the pH value is kept at ≤ 8.0. This configuration not only improves the cleaning efficiency but also effectively improves the quality of the final regenerated PET bottle flakes.

Display of Plastic Chips Washing Machine

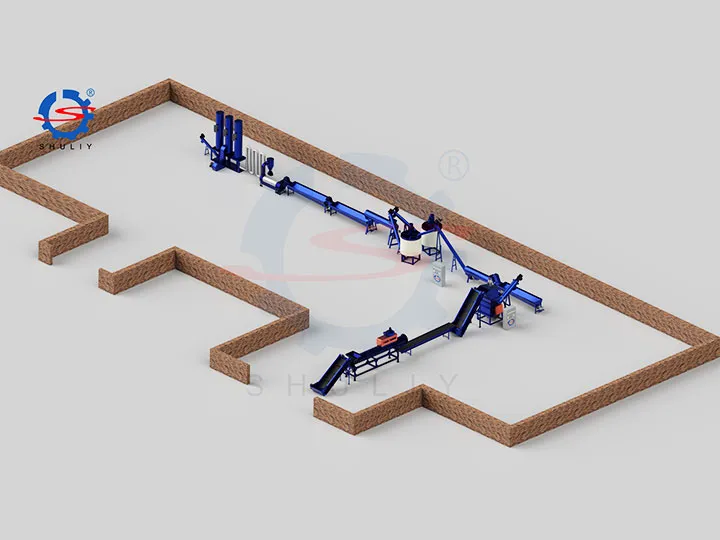

Recommended PET Bottle Recycling Machine

The sink float tanks plastic scraps separation works in concert with the plastic label removing machine, PET bottle crusher, horizontal dryer, and other equipment to build a complete plastic bottle recycling plant that effectively processes waste plastic bottles into renewable PET bottle flakes.

Its efficient cleaning and separating ability significantly improves the efficiency and capacity of the recycling plant. Therefore, the plastic float sink tank has become an indispensable equipment in the PET bottle recycling plant, providing reliable technical support and guarantee for the recycling of plastic bottles.