PET bottle crushing machine is one of the most important machines in PET bottle recycling line, mainly used for crushing plastic bottles into PET flakes, and its production capacity ranges from 500-3000kg/h. Shuliy is well known among PET bottle scrap crusher manufacturers for its high-performance machines. These PET bottle crushers have a strong crushing capacity and are preferred for their low cost, durability, and environmental friendliness.

We offer a wide range of PET bottle crushers for you to choose from in terms of model, capacity, and appearance to meet the needs of different customers. In addition, we can also customize the machine to your specific requirements to ensure it fits perfectly into your production process and space layout. This flexible customization service allows our plastic bottle crusher machine to maximize your specific needs, and improve efficiency and productivity.

Introduction of PET Bottle Crushing Machine

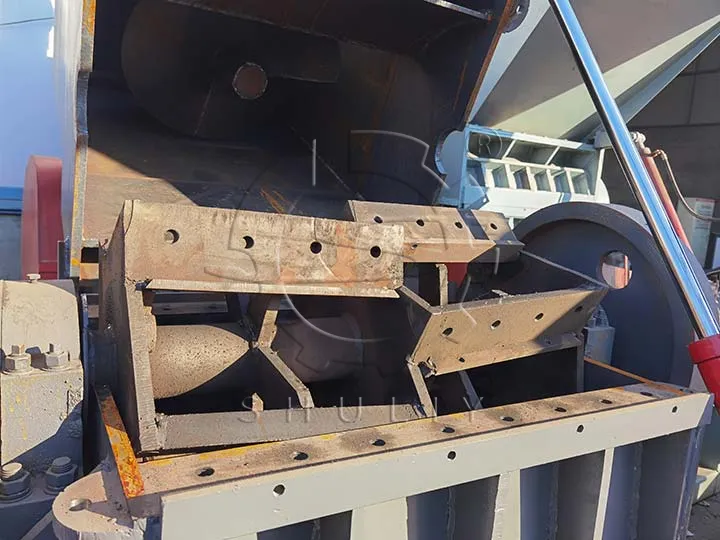

The plastic bottle crusher machine is an efficient machine designed for processing waste PET bottles. The machine adopts advanced 9CrSi material blade and cutting technology, which can quickly and efficiently crush PET bottles into uniform small pieces for subsequent cleaning and recycling.

Our PET bottle crushing machine has a sturdy structure and is easy to operate, suitable for recycling operations of all sizes. Its highly efficient crushing capacity and low energy consumption features not only improve productivity but also reduce operating costs, making it an ideal choice for recycling companies.

plastic bottle crusher machine

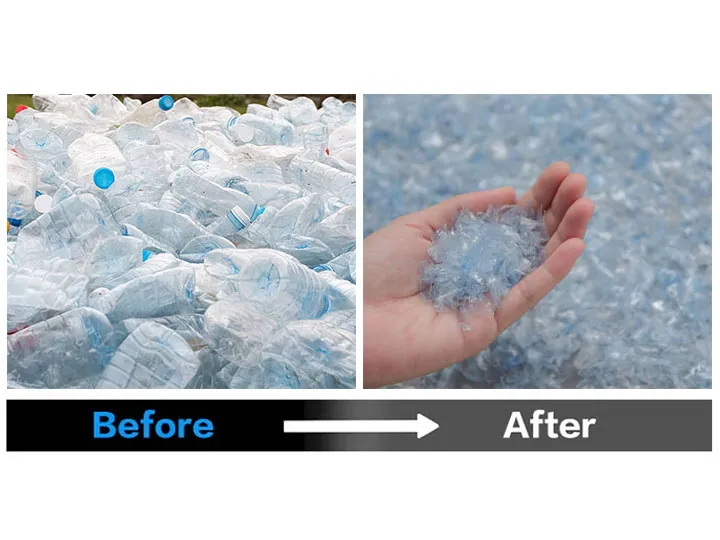

Raw Materials & Finished Products of Plastic Bottle Shredder

PET bottle shredder is mainly used to process all kinds of waste PET bottles and containers. These raw materials include beverage bottles, food packaging bottles, cosmetic bottles, and other different types of PET plastic products. Through the efficient processing of the shredder, these raw materials are crushed into small particles or fragments for subsequent recycling and processing.

These flakes can also be further cleaned and dried to make higher-value recycled PET bottle flakes. Finished PET flakes can be used for a variety of recycling applications, such as making recycled PET pellets for the production of new plastic products, or used directly in the textile industry to make polyester fibers.

Features of Plastic Bottle Crusher

- This water bottle crusher machine is widely used, it can crush PET bottles and PVC, also can crush PP PE plastic.

- The tool of plastic bottle crusher machine is made of 9CrSi material, a special alloy steel material blade after hardening treatment, fast cutting speed, durable blade, and can be ground for repeated use.

- PET bottle crushing machines are easy to operate, save labor, and have higher output under low power consumption. It effectively reduces the production cost of customers.

- The rotary knife of the PET crushing machine is designed with a scissor-cutting action and an effective cutting angle to ensure effective grinding.

- The structure and color appearance of the Shuliy plastic bottle crusher may vary due to version updates and model differences. We provide customized service for plastic crushers, welcome to contact us for a customized solution that suits your needs.

PET Bottle Crushing Machine Working Principle

The working principle of the PET bottle crusher is to produce strong shearing force and impact force by motor-driven blade rotation, which crushes PET bottles and other plastic materials into small particles. After the raw material enters the crusher, it is sheared and torn by the rapidly rotating blades until it reaches the required particle size.

The whole process controls the particle size through a screen to ensure the uniformity of the finished product. The screen size of the PET bottle crushing machine is 16-18mm, which can be adjusted according to the customer’s specific needs. The crushed PET chips can be directly cleaned and reprocessed, providing high-quality raw materials for subsequent recycling.

Plastic Bottle Shredder Application Video

PET bottle crushing machine plays a vital role in PET bottle washing recycling line. It can efficiently crush the waste PET bottles into small particles for subsequent cleaning and reprocessing treatment.

Through crushing, the volume of PET bottles is greatly reduced, improving cleaning efficiency and cleaning effect. The crushed PET pellets can more easily remove oil, mucus, and label residues from the surface, laying a solid foundation for the production of high-quality recycled PET bottle flakes.

The video below shows the important role of a PET bottle shredder machine and the complete PET bottle recycling process for your viewing.

Parameters of Plastic Bottle Shredder

Shuliy PET bottle crushing machines are available in a wide range of models to meet different processing needs. These plastic bottle shredder machines have highly efficient processing capacity and are suitable for crushing and reusing a wide range of PET bottles such as various mineral water bottles, carbonated beverage bottles, and many more.

| Model | SL-60 | SL-80 | SL-100 | SL-120 |

| Capacity (kg/h) | 500 | 1000 | 1500 | 3000 |

| Motor (kW) | 22 | 37 | 75 | 90 |

| Height (m) | 1.8 | 2.6 | 2.6 | 2.6 |

| Thickness of the knife (mm) | 30 | 40 | 40 | 40 |

| Plate thickness (mm) | 16 | 20 | 30 | 30 |

In addition to the models listed above, Shuliy also provides more plastic crushers with different specifications and power to meet the needs of different industries and customers. If you have any questions or need further information about other models, please feel free to contact us, we will be happy to provide you with service and consultation.

Correct Use of PET Bottle Shredder Machine

- First of all, the PET shredder machine should be placed smoothly to prevent the machine from falling on its side during operation. It is best to place it in a flat and ventilated room, which can effectively ensure the normal heat dissipation of the motor and effectively prolong its service life.

- Before starting, turn the belt pulley by hand to make sure the knife frame is flexible and reliable in operation and whether there is any collision in the crushing chamber. After starting, make it idle for 1-2 minutes, no abnormal phenomenon before feeding.

- When crushing, feed the material at a uniform speed, not too much at a time to prevent blocking the crushing chamber.

- Keep the feeding speed of the crusher evenly to prevent overload or no load. Prohibit metal and other hard objects from entering the machine to cause unnecessary damage.

- Before starting the plastic bottle crusher machine for the second time, clean up the residual crushed material inside the cutting chamber, which can reduce the resistance of the motor starting and prolong the service life of the machine.

Maintenance of PET Bottle Crusher Machine

- The PET bottle crushing machine should be placed in a ventilated position to ensure that the motor works heat dissipation, to extend its life.

- Regularly check the tool screws, and the brand new plastic bottle shredder after 1 hour of use, with tools to tighten the dynamic knife, fixed knife screws, to strengthen the blade and the fixity between the knife frame.

- The bearings should be filled with lubricant regularly to ensure the lubrication between the bearings.

- To ensure the sharpness of the cutting edge of the tool, the tool should always be checked to ensure its sharpness and reduce unnecessary damage to other parts caused by the dullness of the blade.

- Regularly check whether the belt is loose, timely tightening.

- The PET bottle crusher should be kept well-grounded.

Successful Case of PET Bottle Crushing Machine

PET bottle crushing machines can crush most of the waste plastics and reuse some waste plastics and it plays an important role in PET plastic bottle recycling line. Therefore plastic waste crusher is very popular in Southeast Asia, Africa, the Middle East, and Central America. Shuliy plastic crusher has been successfully sent to many other countries. Below are specific examples of exports.

Plastic Bottle Crusher Machine Installation in Nigeria

This Nigerian customer plans to open a plastic recycling plant in the local area and purchased the PET bottle recycling machine and plastic pelletizing equipment from our company. Our engineers will go to the local area to assist customers with installation on-site.

PET Bottle Crushing Machine Arrives In Mozambique

We have received feedback from our customer in Mozambique that the SL-80 PET bottle shredder he ordered from our company has arrived successfully. The capacity of this machine is 1000kg/h, the power is 37+4+3kw, and the appearance of the machine is customized according to customers’ requirements.

How To Buy Plastic Bottle Shredding Machine?

As a professional PET bottle crushing machine manufacturer, we provide you with all-around buying guidance to make sure you can choose the most suitable PET bottle crusher. First, you can learn more about the equipment through our product consultation channel. Next, according to your production needs, we will help you determine the required output and configuration.

If there are special requirements, we can customize the plan for you. After determining the plan, both parties reach a cooperation agreement, and we will immediately arrange for the production and shipment of the equipment.

After the arrival of the equipment, we provide door-to-door installation services to ensure the smooth commissioning of the equipment. Whether it is pre-consultation or after-sales service, we are dedicated to providing you with the best quality support and service.