The PET bottle flakes hot washing tank is a specially designed machine for PET bottle flakes washing lines, designed to effectively remove oils, slimes, and labeling residues from bottle flakes and bring them back to clean standards.

By heating water and lye, the machine utilizes high temperatures and chemical reactions to thoroughly clean bottle flakes and ensure they meet high-quality standards for recycling.

With its high efficiency and stable cleaning performance, the PET flakes hot washing machine has become an indispensable and important equipment in the PET bottle flakes recycling process.

The video below shows the use of PET flakes hot washing machine in a plastic washing recycling line. After watching the video, we will continue to show you our equipment.

The Role of PET Bottle Flakes Hot Washing Machine

PET flakes hot washing machine plays a vital role in the cleaning process of PET bottle flakes. Specifically, the machine is capable of:

- Removal of grease and mucus: Utilizing high temperature and lye, grease and mucus are completely removed from the surface of the bottle flakes, leaving them clean.

- Removal of labeling residues: The high-temperature hot washing process can effectively dissolve and remove labeling residues on the bottles and ensure that the surface of the bottles is smooth and residue-free.

- Improvement of cleaning efficiency: By hot washing, the cleaning efficiency can be greatly improved, reducing the workload and difficulty of the subsequent cleaning steps.

Precautions For Use Of The Machine

To ensure the quality of the final PET bottle flakes, there are several points to keep in mind when using this machine:

- Waste Temperature Control: When cleaning, the water temperature should be maintained between 85-95 degrees to ensure optimal cleaning results.

- Washing Time: Washing time should be controlled in 30-45 minutes, too long or too short may affect the cleaning effect.

- Use of Lye: It is necessary to add an appropriate amount of lye to ensure that the pH of the cleaning process is less than or equal to 8%.

- Regular Maintenance: Machines require regular inspection and maintenance to ensure that they are operating in optimum condition and to prolong their service life.

Advantages of PET Flakes Hot Washing Tank

Highly Efficient Washing

The hot washing tank utilizes 85-95 degrees high-temperature water for washing, and can effectively dissolve grease and label residue on the surface of bottle flakes. The cleaning effect is further enhanced by adding an appropriate amount of lye.

Thorough Removal of Label Residue

The combination of high temperature and lye effectively dissolves labels and adhesives, ensuring that there is no residue on the surface of the bottle flakes and improving the quality of the recycled flakes.

Improved Washing Efficiency

The automated design of the hot washing tank enables continuous cleaning operations, reduces manual intervention, and improves work efficiency.

Customized Configurations

Depending on the cleaning needs, the water temperature and cleaning time can be adjusted to ensure optimal cleaning results. According to the customer’s production line demand, the capacity and model of the PET bottle flakes hot washing machine can be flexibly configured to adapt to different scales of the production line.

Parameters of PET Bottle Flakes Hot Washing Machine

| Voltage | 380V, 50HZ, 3phase electricity |

| Motor | 4KW |

| Electromagnetic heating power | 80KW |

| Diameter | 1300mm |

| High | 2000mm |

| Outer wall thickness | 4mm |

| Thickness of the bottom of the pot | 8mm |

| Control method | With separate electromagnetic control cabinet |

Display of PET Bottle Flakes Hot Washing Tank

Recommended PET Bottle Washing Line

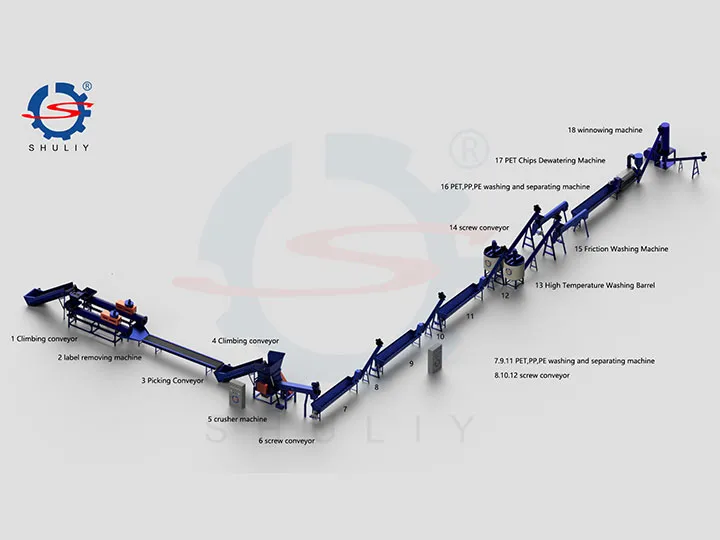

PET bottle flake hot washing tank is suitable for PET bottle washing lines of various sizes. Whether it is a small recycling enterprise or a large-scale recycled plastics processing plant, the machine can effectively improve the cleaning quality of PET bottle flakes and meet the high standard of recycling needs.

The whole PET bottle washing line includes PET bottle label remover, PET bottle crushing machine, PET flakes washing machine, plastic dewatering machine, etc. The plastic bottle recycling line is mainly used for processing plastic bottles removing labels, crushing, high-temperature cleaning, dewatering, and drying.

We have rich experience in tailoring cleaning and recycling solutions and equipment configuration according to customers’ raw materials and needs, which effectively improves the quality and market competitiveness of recycled materials and realizes the recycling of resources.