Our plastic film recycling line specializes in converting waste plastic film into homogeneous plastic pellets. It has an efficient and stable production capacity ranging from 100-500kg/h to meet the needs of customers of all sizes.

The plastic pelletizing line offers several significant advantages, including high energy efficiency, ease of operation, low maintenance costs, and excellent pellet quality. Advanced technology and high-quality materials are used to ensure long-lasting durability and stable operation.

Whether you need to improve production efficiency or increase the reuse of waste plastics, our plastic film recycling machines are the ideal choice. The video below shows the complete process of plastic film pelletizing, which is described in more detail in the following article.

What is A Plastic Film Recycling Line?

A plastic film recycling line is a specialized system designed to process and recycle various types of waste plastic films, such as agricultural films, packaging films, and industrial films. This line typically includes equipment for shredding, washing, drying, and pelletizing the plastic materials. Our plastic film recycling machine is equipped with advanced technology to ensure high efficiency and consistent output.

We offer customizable solutions to meet the specific needs of our customers. Customization options include adjusting capacity (ranging from 100 kg/h to 500 kg/h) and equipment configurations to suit your facility layout and production requirements.

If you want to know how to customize the plastic film recycling line, you can leave a message on our website. Our professional sales manager will give you a detailed introduction as well as send you a quotation.

Plastic Film Granulation Process

Are you curious about how waste plastic films are transformed into valuable plastic pellets? Let’s take a closer look at the various steps of the process, from shredding and washing to extruding and pelletizing.

- The plastic waste is conveyed to the waste plastic crusher through the conveyor, and the plastic waste is initially crushed into smaller-sized plastic flakes.

- The crushed plastic sheet enters the plastic washing tank to clean off impurities, mud, and sand.

- Entering the plastic dewatering machine to dry the plastic pieces.

- The dried plastic pieces are then passed through a pelletizing system that melts the wet plastic into a paste, and the plastic pelletizer will produce hot long strips, which are then cooled in a cold water tank.

- Through the plastic granule cutter, the long strips are uniformly made into plastic pellets of uniform size. Finally, these recycled pellets will be stored in a storage bin.

Advantages of Shuliy Plastic Film Recycling Machine

High Capacity Range: Our plastic film recycling lines have a wide range of capacities, from 100kg/h to 500kg/h, and can be customized for larger capacities, which can meet the needs of enterprises of different sizes.

Premium Finished Product Quality: advanced crushing, cleaning, dewatering, and pelletizing equipment is used to ensure the production of plastic pellets of excellent quality. The pellets produced have high purity and consistency, which are suitable for the production of various highly demanding plastic products.

Automation And Efficiency: Our plastic film recycling line is equipped with an automated control system to ensure precise operation of each step, reduce manual intervention, and increase production efficiency.

Flexible Customization: According to the specific needs of customers, we can flexibly adjust the equipment configuration, providing a variety of solutions from complete production lines to individual equipment.

Raw Materials & Finished Products of Plastic Film Recycling Line

Raw materials are the main focus that customers must pay attention to when engaging in the recycling business. Plastic film recycling lines cover a wide range of raw materials, including all kinds of waste plastic films, such as shopping bags, packaging films, industrial films, agricultural films, cling films, PP raffia bags, cement bags, woven bags, and so on.

After treatment through the processes of crushing, washing, and granulation, it is transformed into finished products in granule form. These granules can not only be sold but used again in the production of plastic products. Our plastic film recycling lines ensure that the quality of plastic pellets produced is exceptional, which is a distinct advantage for our customers.

Recycled plastic pellets are mainly differentiated into grades according to the different raw materials used and the characteristics of the processed plastic pellets, which are generally divided into one, two, and three levels of material.

First-grade material is the processing of better quality or unused plastic raw materials, with these as raw materials processed out of the pellet, transparency is better, and its quality can be compared with the new material, so the first-grade material.

Our plastic pelletizing line can process first-grade recycled plastic pellets. Generally, plastic producers will produce trimmings or unused waste materials during the production process, which are of high purity and quality. With our pelletizing line, these wastes can be effectively recycled to produce recycled plastic pellets that meet the standard of Grade 1 material.

The second-grade material refers to the raw material that has been used once but has not been exposed to the wind and sun, so its quality is also very good, and the transparency of the processed granules is good, so it is the second-grade material. The average plastic recycling manufacturer produces secondary plastic pellets.

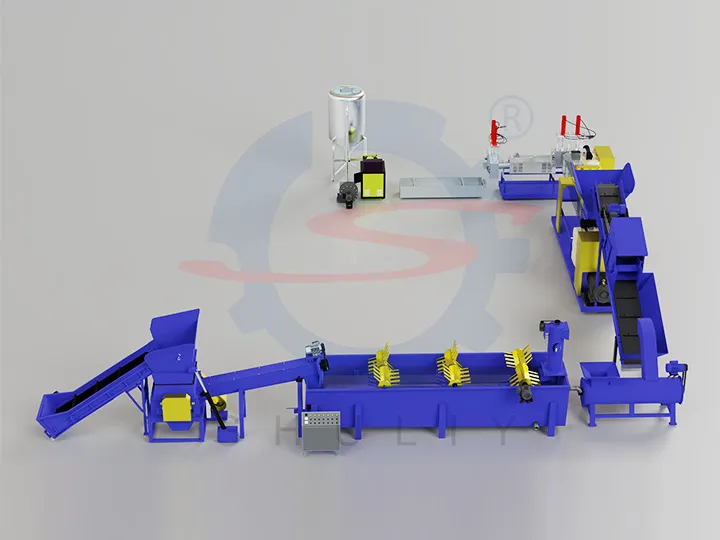

3D Video of Plastic Pelletizing Line

The 3D plastic pelletizing video gives you a better visualization of how each piece of equipment operates. Besides, we can draw detailed 3D drawings for you according to the site layout and machine configuration requirements provided by customers.

Our professional team will accurately measure and analyze the site according to the actual situation to ensure a reasonable layout and smooth operation of the equipment.

How to Get High-quality Recycled Plastic Pellets?

Producing high-quality recycled plastic pellets not only helps customers improve production efficiency and product quality but also brings them significant economic benefits and competitive advantages in the market. Several elements of how to get high-quality plastic pellets in a plastic film recycling line.

Materials

If you want to produce high-quality plastic pellets with your plastic film recycling machine, it is essential to choose plastic raw materials that are recycled as few times as possible. The more times the plastic is recycled, the more impurities there will be in the batch.

Material Moisture Content

Plastic raw materials with high moisture content should not be directly base granulated. This can lead to a large number of pores on the surface of the final plastic pellets after hot melting, plasticizing, extruding, cooling, and pelletizing.

We recommend that the moisture content of the raw material should not exceed 6%, thus avoiding the creation of porosity in the final plastic pellets.

Efficient Plastic Granulating Equipment

Plastic recycling pelletizing machines melt waste plastic at high temperatures to ensure that the raw material is fully melted and achieves the appropriate fluidity.

It can precisely control the pressure and speed of the extruder to ensure that the plastic pellets are subjected to uniform force during the extrusion process and avoid changes in the shape and size of the pellets.

Related Machines of Plastic Film Recycling Line

plastic Waste Shredder

This plastic crusher machine is mainly for recycling plastic and is suitable for crushing plastic film. The plastic film shredder is equipped with specially treated rotating knives inside, which can crush soft materials into small pieces in a short time. The plastic crusher blades can be resharpened to improve durability.

The screen size of the machine is between 40-50mm. When processing the film material, you can choose to add a blower to the machine, or you can choose wet crushing, which can better extract the film material.

Plastic Rinsing Tank

The plastic film washing machine effectively removes stains from plastics and is made of stainless steel or iron plates. The size, as well as the number of this plastic washing machine, can be customized according to the degree of dirtiness of the raw material.

Plastic Drying Machine

The vertical type dewatering machine is mainly used for the conveying process of plastic soft material after rinsing, to replace the manual fishing material, and to increase the cleaning and automatic high-speed dewatering function, to achieve the remarkable purpose of saving labor and electricity consumption, and at the same time with the automatic conveying device to form an automatic assembly line production.

Plastic Granulator

Our plastic pelletizing machines are designed to produce high-quality plastic pellets using state-of-the-art technology and design. The advantage lies in the highly efficient melting and extruding capabilities, which ensure that the plastic raw material is fully melted and uniformly extruded to produce uniformly sized and shaped pellets.

Cooling Tank

The cooling tank is made of stainless steel, which does not rust or corrode. It is mainly used to cool the soft ribbon material extruded from the plastic granulator to harden it. Through cooling, the surface and interior of the plastic lengths can cool and solidify quickly, ensuring that they are stable in shape and size. This is essential for subsequent cutting and processing, ensuring that the final plastic pellets produced are uniform in size.

Plastic Granule Cutter Machine

Plastic pellet cutting machines are capable of cutting with high precision, ensuring that each pellet is uniform in size and shape. Its cutting speed can be adjusted to suit different production needs and capacity requirements.

Parameters of Plastic Film Recycling Line

After introducing the functional features of each machine, here are the detailed parameters of each plastic recycling machine for your reference. Each of our machines offers a variety of models to meet production requirements of different sizes and needs.

| NO. | Item | Technical data |

| 1 | Conveyor | Power: 3kw Size: Length 5m Width: 0.8m Capacity: 1000-1200kg/h |

| 2 | Plastic Shredder Machine | Model: LY-F300 Power: 7.5kw Capacity: 800kg/h |

| 3 | Automatic Feeder | Power: 3kw Capacity: 800-1200kg/h |

| 4 | Main Plastic Granulator | Model: SL-220 Screw diameter: 220mm Screw length: L1.6m Motor: 22+18.5kw |

| 5 | Vice Plastic Granulator | Model: SL-260 Screw diameter: 260mm Screw length: 3.6m Motor: 110kw |

| 6 | Plastic Cutter Machine | Model: LY-F300 Power: 7.5kw Capacity: 800kg/h |

| 7 | Plastic Pellet Bagging Machine | Model: LY-F300 Power: 7.5kw Capacity: 800kg/h |

Trade Cases of Plastic Recycling Machine

Plastic Granulating Line Successfully Shipped To Côte d’Ivoire

This customer from Côte d’Ivoire is an old customer of ours and chose us again through his trust in us. Sunny, our sales manager, communicated with the customer in detail and recommended a solution for him.

Now, a whole plastic pelletizing line was successfully sent to Cote d’Ivoire, and the customer was very satisfied with the Shuliy plastic recycling granulator machine and the service attitude.

Plastic Recycling Process Equipment Sent To Germany

A customer from Germany customized plastic recycling machines from Shuliy to process local waste. To meet the specific needs of our German customers, we have made several customizations to our equipment. For example, we have adapted the size, configuration, and appearance of the machine to the customer’s site conditions and production requirements.

After the production of the equipment was completed, we promptly arranged for packaging and shipping. Our logistics team tracked the progress of the transport to ensure that the equipment could be delivered safely and on time to our German customers.

One-Stop Buying Solution For You

Leaving a message on our website is the first step to begin the process of purchasing a plastic recycling machine. By leaving a message, you can express your needs and interests, and our professional sales managers will communicate with you in detail to ensure that your specific needs and application scenarios are understood.

If you want to know more directly about our plastic recycling machines, you are welcome to visit our factory. During the factory tour, you will be able to see our equipment and production process up close and have a face-to-face product consultation and discussion with our technical team.

Once the order is confirmed, we will provide you with a one-stop solution. From product customization, and manufacturing to logistics, our team will follow through to ensure on-time delivery. In addition, we also provide global on-site installation services to ensure that the equipment is ready for production after installation and commissioning at your factory.

Through these steps, we are committed to providing our customers with efficient and reliable plastic recycling machine solutions that ensure your production process runs smoothly and meets your production needs and quality standards.

Plastic Recycling Equipment Cost

Welcome to learn more about our plastic recycling granulator machine! We offer a wide range of plastic pelletizing plants in various sizes and capacities that can be customized to meet your production needs. Our plastic recycling process equipment is highly efficient and stable, capable of converting waste plastics into high-quality pellets for a wide range of plastic product manufacturing applications. Whether you need a small or large plastic pelletizing production line, we can provide you with professional solutions. Please feel free to contact us and we will be happy to provide you with detailed product information and quotation!