The horizontal foam crusher is an efficient and reliable machine designed to process and crush a wide range of EPS foam materials. With its compact design and easy operation, the machine is capable of quickly pulverizing large pieces of EPS foam into small, uniform pieces. The size of the crushed EPS foam particles is greatly reduced, making it easy for granulation, as well as storage and transportation.

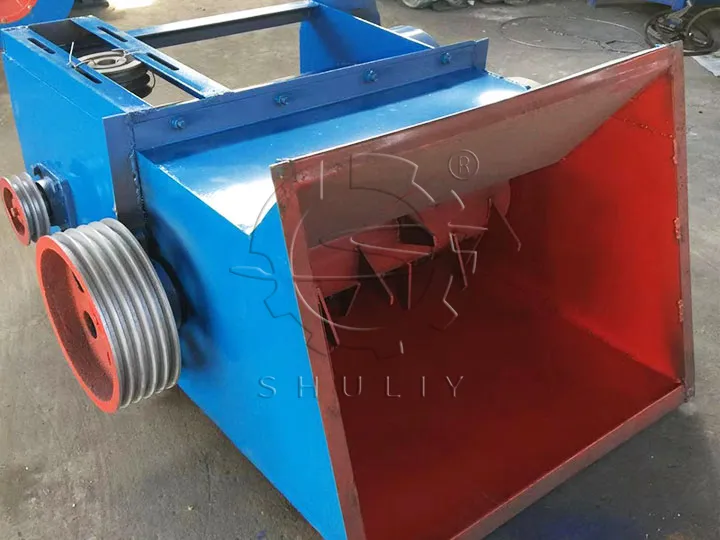

Shuliy Horizontal Foam Crusher

Our styrofoam shredder adopts high-quality knives and a powerful power system to ensure long-term stable operation with low maintenance requirements. It is widely used in all kinds of recycling stations, waste treatment plants, and manufacturing enterprises, providing an ideal solution for realizing the efficient recycling of foam materials.

If you want to know if the horizontal foam crusher can handle your raw materials, read on, the applicable raw materials and the application of this styrofoam shredder are described next. Or you can directly leave a message on our website, our professional sales manager will recommend you the right machine according to your raw materials and needs.

Applicable EPS Foam Raw Materials

EPS foam shredder is mainly used to process various types of EPS foam materials, including packaging foam, construction waste, disposable tableware, thermal insulation boxes, and so on. The raw materials can be large pieces of EPS foam or smaller fragments, which are crushed into uniform small particles or chips after being processed by the styrofoam shredder machine.

The volume of the crushed finished product is greatly reduced, which is convenient for storage and transportation, and also lays the foundation for subsequent reprocessing and recycling. These crumbs can be further used in the production of recycled EPS foam products, realizing the effective recycling of resources.

How Is The Styrofoam Shredder Applied?

The horizontal foam crusher can be used with an EPS pelletizer for an efficient foam waste recycling process. By pulverizing these foam materials into small pieces, the pulverizer is ready for the subsequent recycling process. The crushed foam material can be fed directly into the EPS granulator for processing to produce high-quality recycled pellets for use in the manufacture of new products.

Features of Styrofoam Shredder Machine

Airflow Conveyance: Horizontal foam crushers are usually equipped with a fan or blower system that utilizes a strong airflow to convey the lightweight foam pieces through a pipe to the hopper and onto the EPS granulator.

Continuous Conveying System: The styrofoam shredder and conveying piping is usually a continuous system where the pulverized foam pieces can be conveyed to the hopper without stopping, which keeps the whole production line running smoothly.

High-efficiency Crushing: The EPS foam crusher is equipped with powerful blades, which can quickly and efficiently crush large pieces of foam material into small pieces and improve the efficiency of subsequent processing.

Basic Components of EPS Foam Shredder

Hopper: The entry point of the EPS foam where the material is fed into the EPS foam shredder.

Cutting chamber: The area where the crushing process takes place, housing the rotating blades or knives that break down the foam.

Motor and drive system: Powering the plastic foam shredder, the motor usually ranges from electric to hydraulic depending on the size and requirements of the machine.

Discharge system: Typically airflow conveying, the machine is usually equipped with a fan or blower system that utilizes a powerful airflow to transport lightweight foam pieces through a pipe to a hopper.

Parameters of Horizontal Foam Crusher

| Type | Contour size(mm) | Input size (mm) | Power (KW) | Capacity (KG/H) |

| 800 | 1250*1290*660 | 800*600 | 5.5 | 250-300 |

| 1000 | 1250*1530*660 | 1000*600 | 5.5 | 300-350 |

| 1200 | 1300*1730*700 | 1200*600 | 7.5 | 400-450 |

| 1500 | 1600*2200*800 | 1500*800 | 11 | 450-500 |

Above are our best-selling plastic foam crusher models, if you have specific production needs or other customized requirements, please feel free to contact us, and we will provide professional solutions.