EPS pelletizing machine, also known as EPS granulator, is a kind of equipment that can produce foam pellets without destroying the original molecular structure. Its main function is to reprocess waste EPS foam into pellets through the processes of crushing, plasticizing, and granulating to facilitate recycling and save storage space. Shuliy is a professional manufacturer of plastic recycling machines, offering plastic foam granulators with a capacity of 150-375 kg/h for making foam pellets for various applications.

Raw Materials of EPS Pelletizing Machine

EPS foam is an ordinary plastic material that is made from polystyrene through a special processing process. It is usually used in packaging materials as well as various household items, such as foam fast food boxes, foam packing boxes, refrigerator outer packaging foam, and other white foam waste.

Structure of EPS Pelletizer

EPS pelletizing machine has a simple and efficient design, which is mainly composed of a main machine, auxiliary machine, die head, grinder, and cooling water tank.

Parameters of Plastic Foam Extruder

These are just a few of Shuliy’s hot-selling EPS pelletizing machines, and we have many more models and sizes to meet the needs of different customers for recycled EPS foam. Our foam granulators accept customization, please contact us immediately if you need to.

| Type | Capacity (KG/H) | Motor (KW) |

| 220 (Double reduction gear) | 150-175 | 15 |

| 270 (Double reduction gear) | 200-225 | 18.5 |

| 220 (Single reduction gear) | 150-175 | 15 |

| 270 (Single reduction gear) | 200-225 | 18.5 |

| 320 (Double reduction gear) | 275-300 | 18.5 |

| 350 (Double reduction gear) | 325-375 | 22 |

Recycling Process of Plastic Foam Extruder

As one of the indispensable pieces of equipment for plastic foam recycling plants, the EPS granulator has a simple and efficient working process. Firstly, the waste plastic foam is crushed by an EPS foam shredder. Then the EPS foam is filled into the hopper and is melted and extruded to the auxiliary machine by the main machine of the EPS granulator. After secondary plasticization, the electric screen changing die filters the impurities and enters the cold pool for cooling then enters the pelletizer for cutting to get uniform EPS pellets.

Advantages of EPS Foam Pelletizing Machine

- The design of the feeding port takes into account the density of different materials, and customers can control the feeding speed by themselves. The temperature control box allows customers to keep track of the EPS pelletizer screw temperature and other working conditions and adjust it according to the color of the pasta to avoid overheating or melting failure, and it also helps to make more transparent pellets.

- The primary and secondary screw barrels are made of imported high-strength and high-quality carbon structural steel, which is solid and durable.

- The primary and auxiliary machines are used for production, and the heating temperature is stable, effectively improving the material’s molecular structure, enhancing air permeability, and significantly improving the granules’ quality.

- Designed for stand-alone use, it can also be used in conjunction with machines such as plastic foam crushers and compactor machines to form an efficient foam recycling plant. In addition, Shuliy offers online installation instructions and other training services to ensure that customers utilize their foam granulators effectively.

- The pellets produced are widely used and in short supply in the market. They are exported to Japan and Korea and are widely praised by users. Its mechanical performance is stable and reliable, and the output depends on the size of the equipment.

FAQ

What is an EPS Pelletizing Machine?

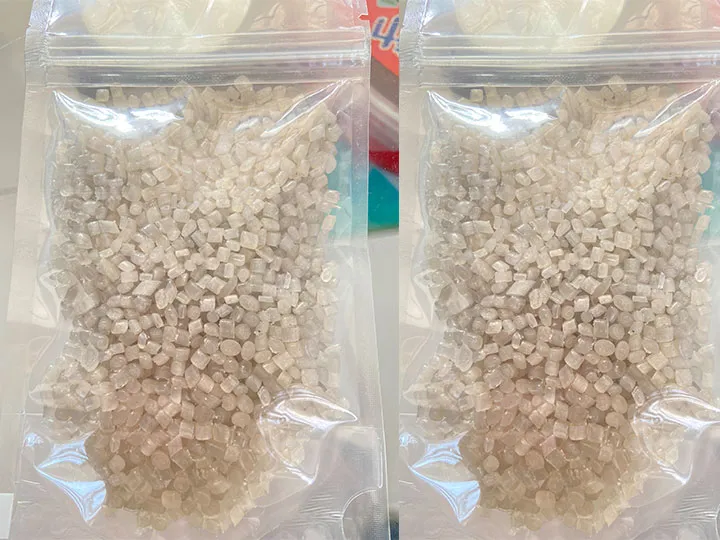

EPS pelletizing machine is designed to recycle waste EPS products or waste EPS beans to produce plastic pellets that can be used in other plastic applications.

Can I Customize The EPS Pellet Size?

Yes, we offer standard-size EPS pellet sizes, but we can also accept custom EPS pellet sizes.

Can I Customize The Length of EPS Pellets?

Yes, the EPS pelletizing machine supports different EPS pellet lengths.

Why is The Color of EPS Plastic Pellets Different From The EPS Pelletizing Machine?

It depends on the quality of the waste EPS product. Cleaner waste EPS can produce better-quality EPS pellets.

Can I Put EPS Pellets Directly Into The Bag After The Pelletizer?

Yes, EPS pellets can be packed directly.