Good news! Shuliy plastic film washing line has been successfully sent to Cote d’Ivoire. During this cooperation, the Ivory Coast customers are very satisfied and highly appreciated the products and services of Shuliy Machinery. If you want to know more about Shuliy’s products and services, please read more detailed information about this transaction!

Client’s needs

Côte d’Ivoire, a country located in West Africa, has a rich resource of waste plastic film. Our client, an experienced plastic recycler, had previously purchased pelletizing equipment elsewhere.

However, there were a number of problems with his existing equipment that affected output and quality. Therefore, he was looking for a reliable partner to provide a set of efficient plastic film washing line to expand production capacity while avoiding the previous problems.

Why did the customer choose Shuliy plastic film washing line?

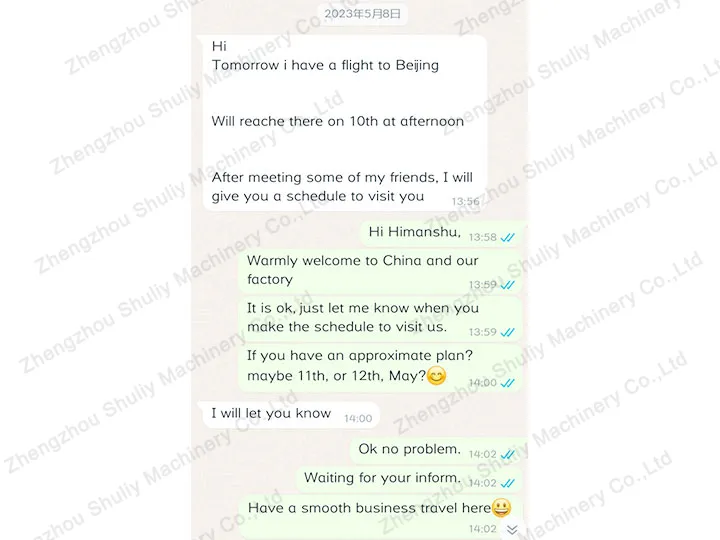

- Professional solution: In the process of searching for a solution, the customer contacted our project manager Helen, who not only listened to the customer’s questions but also answered his concerns in a timely manner. In addition, Helen actively shared the factory video and detailed product information to show the customer the superior performance of shuliy plastic film washing line.

- Superior machine: Our professional answers and attentive communication won the customer’s trust. The customer decided to visit Shuliy factory to have a more comprehensive understanding of the performance and quality of the product. After the site visit, the customer showed high satisfaction with Shuliy plastic film washing line.

Parameters of plastic recycling granulating line

The following are the parameters of this plastic film washing line, the whole pelletizing line can be customized according to customers’ requirements. If you have any questions, please feel free to consult us.

| Machine | Specification |

| Belt conveyor | Length: 5m Width: 1m Power: 2.2kw With magnetic roller |

| Plastic crusher | Model: SLSP-600 Motor power: 30 kw Capacity: 600-800kg/h 10pcs knives Material of knives: 60Si2Mn |

| Powerful double tank cleaning machine & heating tube | Motor power: 7.5kw Dimensions: 5.0m*1.4m*1.6m Diameter: 0.6m*2Blade Thickness: 10mm Outer wall thickness: 4mm Material: Q235 Heating power: 60kw |

| Lifting dewatering machine | Motor power: 7.5kw Dimensions: 2.6m*0.7m Diameter: 0.5m Weight: 450kg Blade thickness: 6mm Outer wall thickness: 4mm Material: Q235 |

| Washing tank | Motor power: 4kw Dimensions: 4.5*1.2*1.3 Power of the gear motor: 1.5kw Weight: 1200kg Blade thickness: 6mm Outer wall thickness: 3mm Material: Q235 |

| Horizontal dryer | Dryness: 98% Motor power: 15kw Dimensions: 2.5m*1.0m Screen: made of 304 stainless steel Blade thickness: 10mm Spindle thickness: 8mm |

| Plastic pelletizing machine | Host pellet making machine Model: SL-150 Power: 37kw 2.3screw Heat method: ceramic heating Hardened gear reducer Second pellet making machine Model: SL-125 Power: 11kw 1.3m screw Heating method: heating ring heating Hardened gear reducer Screw material: 40Cr(High hardness and wear resistance) Sleeve material: heat-treated No.45 steel Double Hydraulic die Power: 3KW(Change net non-stop machine) |

| Cooling tank | Length: 3mMaterial:stainless steel |

| Pellet cutting machine | Converter speed regulation Power: 3kwHob knives |

| Storage bin | Power: 2.2kw A high pressure blower delivers the pellets and removes the water from the pellets. |

Plastic recycling granulating line sent to Côte d’Ivoire