Extrusionsystem des Kunststoffschrottgranulators

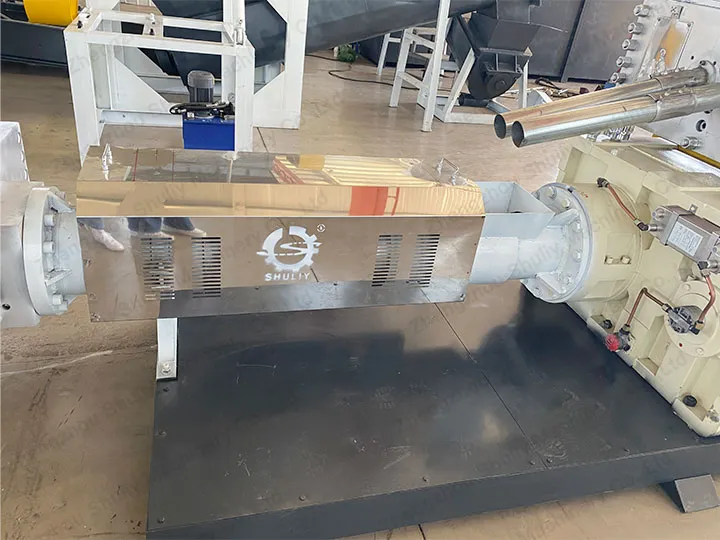

Die Hauptmaschine der Kunststoff-Schredder-Granulator-Struktur ist der Extruder, der aus einem Extrusionssystem, einem Übertragungssystem und einem Heiz- und Kühlsystem besteht. Das Extrusionssystem umfasst eine Schnecke, einen Zylinder, einen Einfüllstutzen und einen Düsenkopf. Der Kunststoff wird durch das Extrusionssystem zu einer homogenen Schmelze plastifiziert und im Prozess der Erzeugung des Arbeitsdrucks kontinuierlich durch den Schneckenausstoß zum Kopf extrudiert.

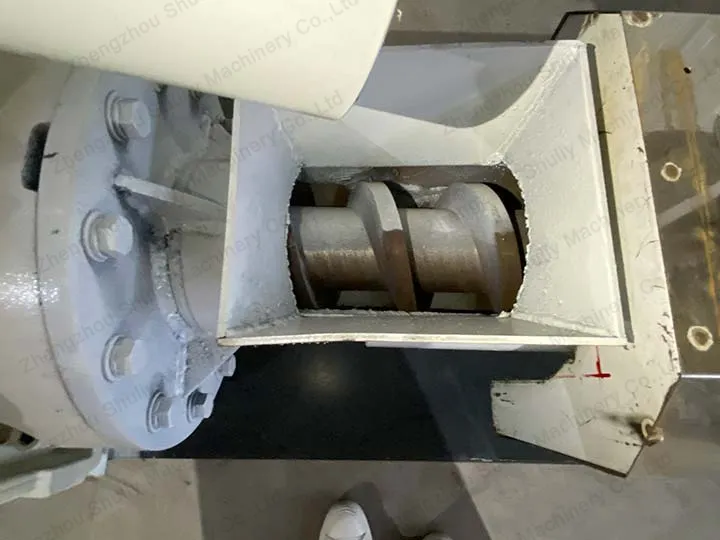

Schnecke: Das Hauptbestandteil des Kunststoff-Schredder-Granulators, das mit der Art und Produktivität des Kunststoff-Schredder-Granulators zusammenhängt, hergestellt aus hochfestem korrosionsbeständigem legiertem Stahl.

Zylinder: Dies ist eine Art Metallrohr, das normalerweise aus legiertem Stahl mit hoher Temperaturbeständigkeit, hoher Druckfestigkeit, starker Verschleißfestigkeit und Korrosionsbeständigkeit gefertigt ist. Der Zylinder und die Schnecke arbeiten zusammen, um das Zerkleinern, Erweichen, Schmelzen, Plastifizieren, Entgasen und Verdichten von Kunststoffen zu erreichen und eine kontinuierliche und proportionale Kunststofflieferung an das Formsystem zu ermöglichen. Im Allgemeinen beträgt die Länge des Zylinders das 18-fache seines Durchmessers, sodass der Kunststoff nach dem Prinzip gründlich erhitzt und vollständig plastifiziert werden kann.

Einfüllstutzen: Der untere Teil des Einfüllstutzens der Kunststofffolien-Recyclingmaschine ist mit einer Absperrvorrichtung zur Regelung und Unterbrechung des Materialflusses ausgestattet, und die Seite des Trichters ist mit einem Schauglas und einer kalibrierten Messvorrichtung versehen.

Düsenkopf: Der Düsenkopf eines Kunststoff-Schredder-Granulators besteht aus einer inneren Hülse aus legiertem Stahl und einer äußeren Hülse aus Kohlenstoffkonstruktionsstahl. Die Aufgabe des Düsenkopfes besteht darin, die rotierende Bewegung der Kunststoffschmelze in eine parallele, gleichmäßige lineare Bewegung umzuwandeln, die proportional und stabil in das Formsystem eingeleitet wird, und dem Kunststoff den notwendigen Druck für die Formgebung zu verleihen.

Übertragungssystem der Kunststofffolien-Recyclingmaschine

Die Funktion des Antriebssystems besteht darin, die Schraube zu betreiben und das Drehmoment sowie die Geschwindigkeit bereitzustellen, die von der Schraube im Extrusionsprozess benötigt werden. Es besteht normalerweise aus einem Elektromotor, einem Reduzierer und einem Lager.

Heiz- und Kühlgerät der Kunststoffrecycling-Granuliermaschine

Heizung und Kühlung sind eine notwendige Bedingung, damit der Kunststoffextrusionsprozess durchgeführt werden kann.

- Heutzutage verwendet die Kunststoffrecycling-Pelletmaschine normalerweise elektromagnetische Heizung. Das Heizgerät erhitzt von außen das Plastik im Fass, sodass es auf die für den Betrieb erforderliche Temperatur erwärmt wird.

- Das Kühlsystem ist so eingerichtet, dass der Kunststoff im für den Prozess erforderlichen Temperaturbereich bleibt. Ziel ist es, eine zu hohe Temperatur zu vermeiden, die die Zersetzung, das Anbrennen oder die Formgebung des Kunststoffs erschwert.