Our plastic film pelletizing machine is a specialized equipment for recycling and processing waste plastic films. Its main function is to convert recycled plastic film through a series of processing steps into homogeneous plastic granules, which can be used as recycled raw materials for the production of new products.

The production capacity of the machine is 180-420 KG/H, which can be adjusted according to the specific needs of customers to ensure that it meets the production needs of recycling enterprises of various scales. Our pelletizing recycling machine offers a cost-effective solution to our customers with its high efficiency, energy-saving, and environmentally friendly features.

Please watch a video before we tell you more about our granulator for plastic recycling.

Raw Materials For Plastic Film Pelletizing Machine

After introducing the role and capacity of the plastic film granulator, you may ask what kind of raw material is suitable for this machine. Our plastic film pelletizing machine is widely used in the processing of all kinds of plastic film wastes such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and so on.

Whether it’s plastic bags, woven bags, agricultural film, packaging film, or industrial film, this machine can efficiently process it and convert it into high-quality recycled pellets. If your business is involved in the recycling and reuse of these waste plastic films, this machine will be ideal for you.

Advantages of Plastic Film Pelletizing Machine

High Efficiency And Energy Saving

Adopting advanced heating technology and an efficient pelletizing system, it can quickly convert plastic film into pellets and improve production efficiency.

Precise Temperature And Process Control

The plastic film pelletizing machine is equipped with an advanced temperature control system and process control technology to ensure that the plastic film is pelletized at the best processing temperature. This ensures stable pellet quality, reduces the waste rate, and improves the market competitiveness of the products.

Versatile and Customizable

Capable of handling a wide range of plastic film types and thicknesses with high adaptability and flexibility. Meet the different production needs of customers, and can be customized according to specific requirements.

Stable Operation And Low Maintenance Costs

The equipment has a solid structure, is easy to operate, and has low maintenance costs, thus reducing the customer’s operating costs.

Plastic Pelletizing Recycling Machine Working Principle

Next, let’s introduce the working principle of the plastic film pelletizing machine.

The material is usually crushed and cleaned before it enters the pelletizing recycling machine, which ensures the quality of the pellets.

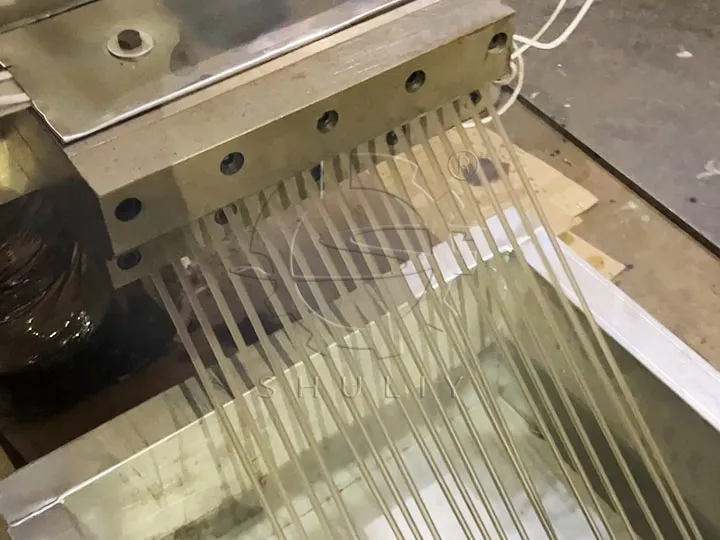

The crushed and cleaned plastic film pieces enter the plastic pellet extruder for melting. The molten plastic is pushed into the extruder’s die head through the rotation of the screw, and the die head extrudes a continuous strip of plastic.

These plastic strips are cooled and cured by a cooling device and finally cut into uniform plastic pellets by a pellet cutting machine. These pellets can be used directly in the production of new products or sold to other manufacturers as recycled material.

Structure of Plastic Pellet Machine

Now we introduce you to the structure of the plastic pellet machine to help you understand the working principle of the machine. The structure of the machine includes the following main parts:

- Feeding system: It is used to feed the crushed waste plastics evenly into the plastic film pelletizing machine. Handling of film material can usually be equipped with an automatic feeding device.

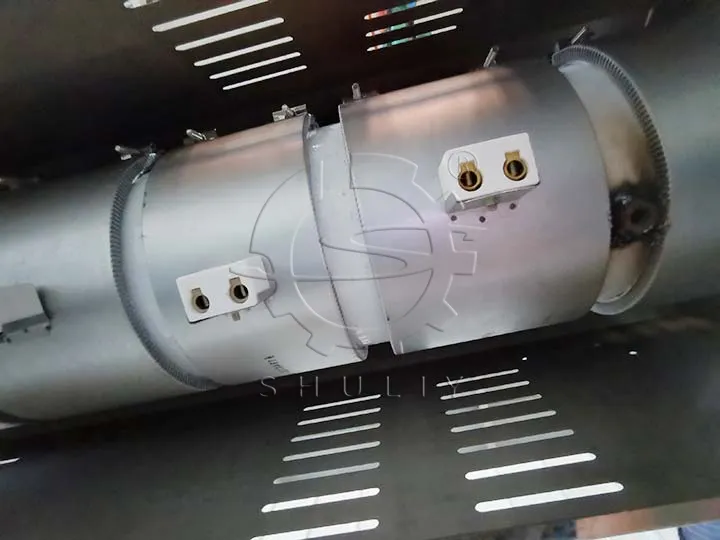

- Extruding system: It is the core part of the plastic pelletizing machine, mainly composed of extruder barrel and screw. The screw rotates in the barrel to heat, melt and push the plastic to the die head.

- Heating system: Includes a heating unit and an electrical control box to control the temperature inside the extruder.

- Die Head: Installed at the outlet end of the plastic film pelletizing machine, the plastic melt is extruded and molded through the die head. The design of the die head determines the shape and size of the extruded plastic strip.

Auxiliary Equipment For Plastic Film Granulator

When processing plastic film material, an automatic feeding device is required on the plastic pellet extruder. The reason for this is that plastic film material is lightweight and tends to drift and accumulate. The automatic feeding device can continuously and evenly feed the film material into the granulator, improve the feeding efficiency, and ensure the continuity and stability of production.

Plastic Recycling Granulator Technical Parameters

Shuliy has a wide range of plastic film recycling machines to help customers improve their plastic recycling efficiency, where the models are named by the size of the screw diameter. Below are some of our hot-selling plastic film pelletizing machines, if you need to know other models of plastic pelletizing machines, please feel free to contact us.

SL-125

Screw diameter: 125mm

Spindle speed: 50-70/min

Main motor power: 30kw

Reducer hard gear: 225

Weight: 1.8T

Size: 2.6*0.7*0.7m

Output: 180KG/H

SL-180

Screw diameter: 180mm

Spindle speed: 40-50/min

Main motor power: 55kw

Reducer hard gear: 280

Weight: 2.2T

Size: 3.2*0.7*0.8m

Output: 350KG/H

SL-220

Screw diameter: 220mm

Spindle speed: 40-50/min

Main motor power: 90kw

Reducer hard gear: 330

Weight: 3.2T

Size: 3.8*1.2*1m

Output: 420KG/H

Heating Methods of Plastic Granulator Machine

Plastic pelletizers typically use a variety of heating methods to heat the barrel to melt and pelletize the plastic material. Below are three common heating methods that you can choose from according to your production needs.

Electromagnetic Heating

- Principle: Through the principle of electromagnetic induction heating, the electromagnetic induction ring is utilized to generate an electromagnetic field around the barrel, thus heating the plastic raw material.

- Advantages: uniform heating, high efficiency, energy saving, and fast response time.

- Suitability: Particularly suitable for applications requiring rapid heating and precise temperature control.

Ceramic Heating

- Principle: Using ceramic heaters to convert electrical energy into thermal energy, the barrel is heated by conducting electric current to the inside of the ceramic resistor body to generate heat.

- Advantages: stable and reliable, not easily affected by changes in ambient temperature, with good high-temperature resistance.

- Suitability: Suitable for long-time stable heating, not particularly demanding temperature requirements of the application.

Ordinary Electric Heating

- Principle: Through the resistance wire or electric heating tube directly heated barrel, the use of electrical energy into thermal energy to heat the plastic raw materials.

- Advantages: simple operation, low equipment cost, easy maintenance.

- Applicability: Widely used in small plastic granulators or equipment requiring simple heating control, temperature control may be slightly worse relative to other methods.

Successful Cases of Plastic Film Pelletizing Machines

Plastic Film Granulator In Operation In Saudi Arabia

When this Saudi Arabian customer came to consult with us, he had already collected a large amount of film material and was planning to open a plastic recycling and processing plant. He needed to process the plastic film into plastic pellets, and after careful communication, chose our plastic film pelletizing machine. With the on-site assistance of our engineers, it was successfully run.

Plastic Pelletizing Recycling Machine Sent To Botswana

We learned about the demand for plastic pellet recycling machines from this Botswana customer’s inquiry. After detailed communication and understanding of the customer’s specific requirements, we provided a customized solution and confirmed the relevant quotation. After the customer confirmed the order, we actively arranged the production and commissioning to ensure that the equipment was shipped on time and arrived at the destination smoothly.

Recommended Plastic Film Recycling Line

To better realize the recycling and reuse of plastic film, it is recommended to match the plastic film recycling line. This plastic pelletizing plant includes plastic crushers, plastic film pelletizing machines, plastic pellet cutting machines, and other plastic recycling equipment for recycled plastic pellets, forming a complete production process that realizes the efficient conversion from waste plastic film to recycled plastic pellets.

Contact Us For The Plastic Granulator Machine Price!

Are you interested in recycling plastic film? If so, we are more than happy to assist you! We specialize in personalized solutions for our customers and make sure to provide you with the best quote for plastic film recycling machines according to your needs and budget. Please feel free to contact us and let’s discuss how best to handle your plastic film recycling needs!