塑料泡沫造粒线主要用于各种废旧泡沫的回收造粒。将废旧塑料破碎成小塑料颗粒,可作为包装材料、绝缘材料等二次使用。泡沫塑料造粒线最重要的设备是塑料泡沫挤出机,它将塑料颗粒熔融并挤出。

What Are EPS Foam And EPE Material?

泡沫EPS是一种常见的塑料材料,由聚苯乙烯经过特殊加工工艺制成。常用于包装材料、建筑材料和各种家居用品。它因其外观而得名,通常呈白色泡沫形式。

Foam EPS is widely used in construction materials because of its excellent thermal insulation and shock absorption properties. However, the manufacturing process of EPS foam generates a lot of waste gas and wastewater, which causes pollution to the environment. The service life of foam EPS is relatively short, which is not conducive to environmental protection and sustainable development.

可发性聚乙烯(EPE),俗称珍珠棉。 EPE由许多通过化学或物理发泡产生的独立气泡组成。 EPE珍珠棉泡棉质轻柔软,在外力作用下吸收冲击力并分散能量,以缓冲物品。广泛应用于高档家具、电子产品、药品等贵重易碎物品的包装。

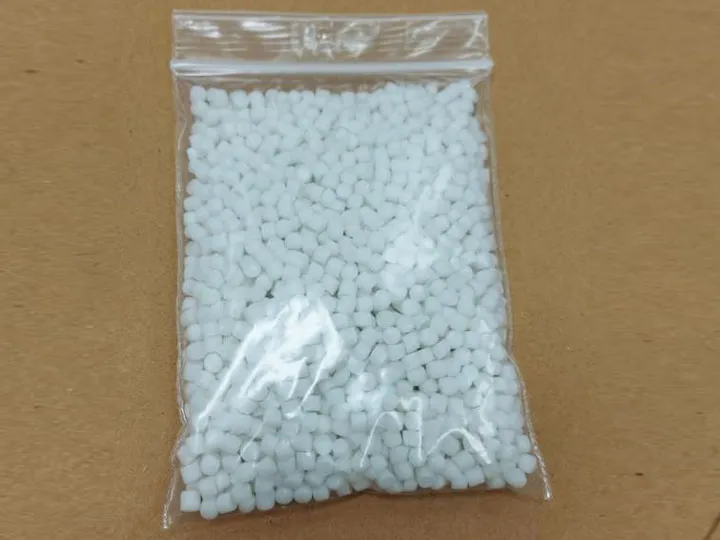

Raw Materials And Final Products

The main source of plastic foam pelletizing line is EPE EPS waste packaging, such as foam fast food boxes, foam packaging boxes, fruit net covers, refrigerator outer packaging foam, and other white foam waste.

Through the plastic foam pelletizing line, EPS and EPE foam are granulated and eventually, new recycled pellets can be obtained. It can be made into other new products to be put into use, and realize the waste to treasure of foam.

EPE EPS Foam Pelletizing Process

As EPE and EPS are made of different materials, their granulation processes are also different. EPE is made of softer material and the EPE granulator comes with a feeding device, so the waste EPE foam can be directly fed into the EPE foam granule machine for processing.

EPS, on the other hand, due to its large size, must first be crushed into small pieces by the foam crusher, and then into the EPS granulator for granulation. The design of this process ensures that each material can be efficiently converted into recycled pellets to meet different recycling needs.

Video of Plastic Foam Pelletizing Line

Equipment Introduction Of Foam Recycling Machine

EPS泡沫熔化机

EPS泡沫熔化机是专门针对废旧发泡聚苯乙烯泡沫(EPS)通过破碎、热熔、挤出成型等方法减少体积而设计的。它最大限度地减少了EPS泡沫产品所占用的体积,并且熔化的材料可用于制造其他塑料产品。

Foam Compactor

After the plastic foam is compressed by the EPS foam compactor, the foam density increases and it is shaped, which is very convenient for transportation and storage. There are two types of compactors: vertical EPS foam compactors and horizontal EPS foam compactors.

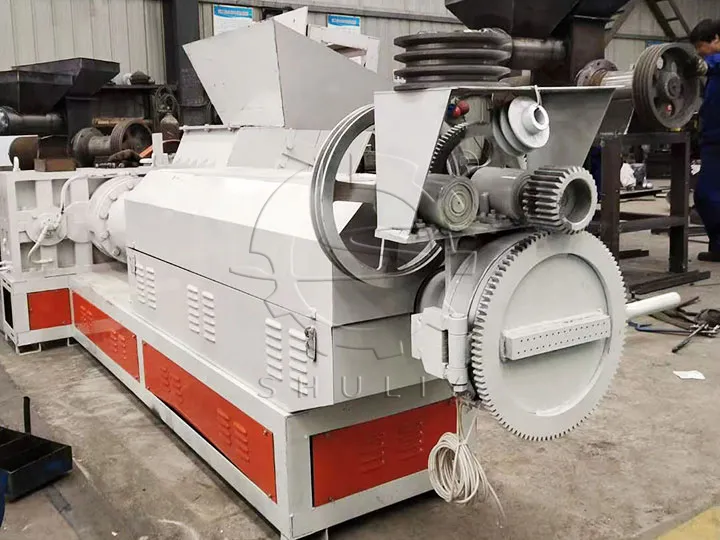

Plastic Foam Granulator

The plastic foam granulator is one of the most important machines in the plastic foam pelletizing line. The granulator can melt and extrude EPE and EPS waste plastics into reusable plastic granules.

冷却槽

The cooling tank is used to cool and harden the extruded plastic long strips of the plastic foam extruder to facilitate the next step of cutting them into uniformly sized pellets.

Plastic Pellet Cutting Machine

The plastic pellet cutting machine can cut plastic long strips into pellets, and the size of the pellets can be adjusted. The main board is set with a stainless steel plate to effectively prevent plastic pellet pollution.

Features of Plastic Foam Pelletizing Line

- 塑料泡沫造粒线工艺简单、技术先进、能耗低、无污染、自动化程度高。

- 产量高、电费低。高性能和低维护成本。

- The high degree of automation and intelligence in the operation of the whole 珍珠棉 EPS foam granulating line. Easy to operate, less space, and operators to use.

- 塑化挤出后颗粒密度高、无气孔、表面美观、产量高、挤出稳定。

Styrofoam Recycling Machine For Sale

We offer a wide range of foam recycling machines to meet the needs of different customers. Our machines not only efficiently compress the foam into blocks for easy storage and transport, but also melt the foam into blocks through hot melt technology to further reduce the volume.

In addition, our foam granulators can process waste foam into high-quality recycled pellets for a variety of manufacturing applications. Whichever type of foam recycling you need, we can provide you with reliable equipment and comprehensive solutions. If you are interested in our foam recycling machine, please feel free to contact us.