EPE foam pelletizing machine is mainly used for EPE foam recycling, processing, and reuse, which is one of the main recycling pieces of equipment in plastic foam granulation plants. After simple processing, the waste EPE foam can be reused to produce plastic products. Shuliy is a professional plastic foam recycling equipment manufacturer, offering various models of EPE foam granulators with a production capacity of 150 to 200 kg/hour.

Raw Materials And Products of EPE Styrofoam Pelletizing Machine

EPE保丽龙造粒机主要用于各种废旧泡沫、珍珠棉的造粒回收,如电器包装泡沫、废饭盒、水果网罩、泡沫边废料等。

How Does a Plastic Foam Pelletizer Work?

EPE泡沫造粒机采用高温熔融挤出工艺,将废旧泡沫、珍珠棉等材料加工成颗粒,经过以下步骤:

Material Heating

废泡沫和珍珠棉等材料首先被送入熔化室,在那里被加热到高温。加热过程使这些材料变成可流动状态。

Extrusion to Form Pellets

The heated material is extruded through the extrusion mechanism to form a pelletized structure. The extrusion process helps in molding the material into the desired shape and size.

Cooling and Curing

形成的颗粒通过冷却系统冷却并固化。此步骤是为了确保颗粒在固态下保持其质量和稳定性。冷却过程使颗粒逐渐凝固成固体形式。

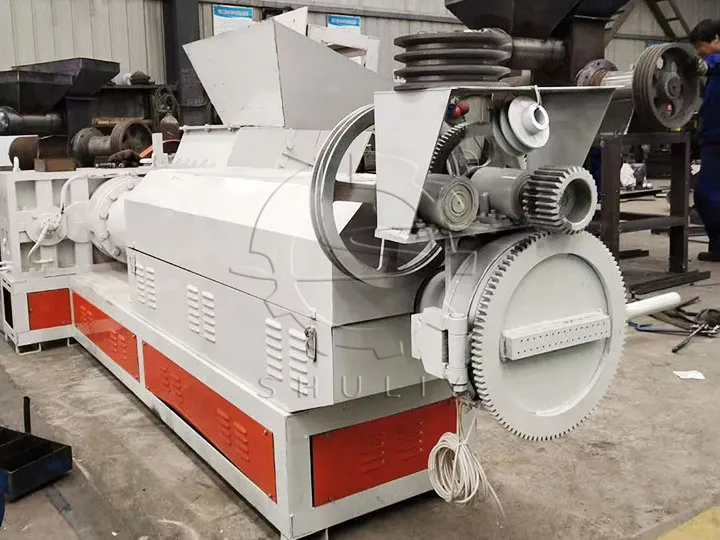

Structure of EPE Foam Pelletizing Machine

EPE foam granule machines mainly include feeding systems, compaction and extrusion systems, vacuum exhaust systems, filtration systems, cutting systems, and drying and packaging systems.

Parameters of EPE Foam Granule Machine

Take the model SL-160 EPE foam pelletizing machine for example. Its machine size is 3400*2100*1600mm, and the size of the feed opening is 780*780mm. Its power is 30kw and its capacity is 150-200kg/hour. The heating method is a heating ring.

Considering that customers have different production needs, we also provide other models and specifications of plastic foam granulators, and the appearance, parameters, and other inventions are accepted to be customized. If you have foam granulation needs you can contact us at any time.

Advantages of Plastic Foam Extruder

- The new generation of waste EPE foam granulators adopts new technology, new design, beautiful appearance, and ease of use.

- 该EPE泡沫造粒机配套设施齐全,可自动连续生产。从原料破碎拉丝到切割成颗粒,全部自动化生产,节省人力。

- EPE泡沫造粒机占地面积小,功耗低,成品质量高,维护方便。

- 定制设计,可单独使用,也可与破碎机和塑料泡沫压实机集成到整个系统中,甚至集成到 塑料泡沫造粒厂.

- 结构的坚固性,即机器重量、材料厚度、机器稳定性和链条驱动强度。

- 以具有竞争力的价格提供维护包,并提供在线安装指导和其他培训服务。

Inquiry for Plastic Foam Extrusion!

As a professional plastic recycling equipment manufacturer, Shuliy is committed to providing high-quality and efficient plastic foam extrusion to meet different customers’ needs. Plastic foam granulator prices vary by model, production capacity, and features, and Shuliy staff will provide you with detailed quote information based on your specific needs. Please feel free to contact the Shuliy team, they will warmly answer any questions you may have about foam granulators and help you choose the most suitable recycling equipment.

Service of Shuliy: Specialized Plastic Recycling Solutions

售前

- 我们提供多种形式的售前服务,如投资预算、制造规划等,让客户以更少的成本做出合理的计划。

- 投资预算:我们提供EPE泡沫造粒机利润分析、辅助设备推荐及相关预算、人力资源配置、预算服务。

- 厂房规划:提供设备基础安装尺寸、设备布局、车间通风、输水等设计。

发售中

- 布局的详细设计,即游行的地点

- Provide technical information on EPE foam granulators and training courses for technicians on safe and reliable standards for installation.

- 设计、制造、安装进度表

促销过后

- 对于购买我们的EPE泡沫造粒机的客户,我们提供免费培训,使他们能够独立使用和维护机器。

- 我们将及时解答客户的技术问题。如果需要,我们将提供现场指导和帮助。

- If customers need new plastic recycling machines, add or modify equipment, we can provide free technical guidance.