EPE foam pelletizing machine is mainly used for EPE foam recycling, processing, and reuse, which is one of the main recycling pieces of equipment in plastic foam granulation plants. After simple processing, the waste EPE foam can be reused to produce plastic products. Shuliy is a professional plastic foam recycling equipment manufacturer, offering various models of EPE foam granulators with a production capacity of 150 to 200 kg/hour.

Raw Materials And Products of EPE Styrofoam Pelletizing Machine

The EPE styrofoam pelletizing machine is mainly used for the granulation and recycling of various waste foam and pearl cotton, such as electrical packaging foam, waste lunch boxes, fruit net covers, foam edge waste, etc.

How Does a Plastic Foam Pelletizer Work?

EPE foam pelletizing machine adopts high temperature melting and extruding process to process materials such as waste foam and pearl cotton into pellets through the following steps:

Material Heating

Materials such as waste foam and pearl cotton are first fed into the melting chamber where they are heated to a high temperature. The heating process turns these materials into a flowable state.

Extrusion to Form Pellets

The heated material is extruded through the extrusion mechanism to form a pelletized structure. The extrusion process helps in molding the material into the desired shape and size.

Cooling and Curing

The formed pellets are cooled and cured through a cooling system. This step is to ensure that the pellets maintain their quality and stability in the solid state. The cooling process causes the pellets to gradually solidify into a solid form.

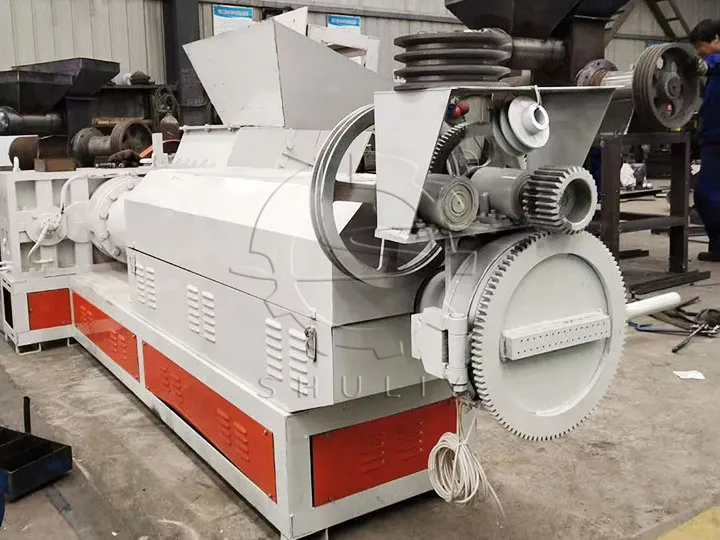

Structure of EPE Foam Pelletizing Machine

EPE foam granule machines mainly include feeding systems, compaction and extrusion systems, vacuum exhaust systems, filtration systems, cutting systems, and drying and packaging systems.

Parameters of EPE Foam Granule Machine

Take the model SL-160 EPE foam pelletizing machine for example. Its machine size is 3400*2100*1600mm, and the size of the feed opening is 780*780mm. Its power is 30kw and its capacity is 150-200kg/hour. The heating method is a heating ring.

Considering that customers have different production needs, we also provide other models and specifications of plastic foam granulators, and the appearance, parameters, and other inventions are accepted to be customized. If you have foam granulation needs you can contact us at any time.

Advantages of Plastic Foam Extruder

- The new generation of waste EPE foam granulators adopts new technology, new design, beautiful appearance, and ease of use.

- This EPE foam pelletizing machine is complete with supporting facilities and can be produced automatically and continuously. From raw material crushing and drawing to cutting into granules, all automatic production saves manpower.

- The EPE foam pelletizing machine covers a small area, has low power consumption, high-quality of finished products, and easy maintenance.

- Customized design, can be used alone or integrated into the whole system with a crusher and plastic foam compactor, or even integrated into the plastic foam pelletizing plant.

- Robustness of construction, i.e. machine weight, material thickness, machine stability, and chain drive strength.

- Maintenance packages are available at competitive prices, with online installation guidance and other training services.

Inquiry for Plastic Foam Extrusion!

As a professional plastic recycling equipment manufacturer, Shuliy is committed to providing high-quality and efficient plastic foam extrusion to meet different customers’ needs. Plastic foam granulator prices vary by model, production capacity, and features, and Shuliy staff will provide you with detailed quote information based on your specific needs. Please feel free to contact the Shuliy team, they will warmly answer any questions you may have about foam granulators and help you choose the most suitable recycling equipment.

Service of Shuliy: Specialized Plastic Recycling Solutions

Pre-sales

- We provide various forms of pre-sales services, such as investment budgeting, manufacturing planning, etc., so that our customers can make a reasonable plan with less cost.

- Investment budget: We provide profit analysis of EPE foam pelletizing machine, and auxiliary equipment recommendation and related budget, human resource allocation, and budgeting services.

- Plant planning: We provide the design of equipment base installation size, equipment layout, workshop ventilation, water transmission, etc.

On-sale

- Detailed design of the layout, i.e. the location of the parade

- Provide technical information on EPE foam granulators and training courses for technicians on safe and reliable standards for installation.

- Schedule of design, manufacture, and installation

After-sales

- For customers who buy our EPE foam pelletizing machine, we provide free training to enable them to use and maintain the machines independently.

- We will answer customers’ technical questions promptly. If needed, we will provide on-site guidance and assistance.

- If customers need new plastic recycling machines, add or modify equipment, we can provide free technical guidance.