EPS造粒机又称EPS造粒机,是一种在不破坏原有分子结构的情况下生产泡沫颗粒的设备。其主要功能是将废旧EPS泡沫经过破碎、塑化、造粒等工序再加工成颗粒,以便于回收利用,节省储存空间。 Shuliy是一家专业的塑料回收机械制造商,提供产能为150-375公斤/小时的塑料泡沫造粒机,用于制造各种应用的泡沫颗粒。

EPS造粒机:专门将废旧EPS泡沫回收成颗粒

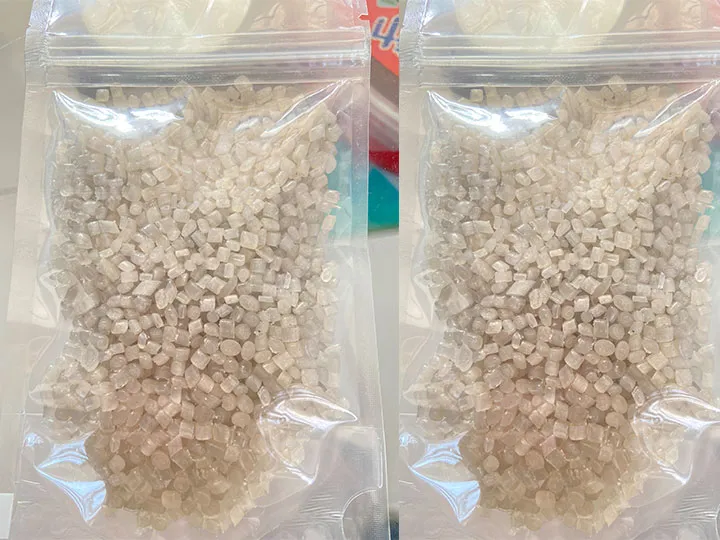

EPS造粒机原材料

EPS泡沫是一种普通的塑料材料,由聚苯乙烯经过特殊加工工艺制成。通常用于包装材料以及各种家居用品,如泡沫快餐盒、泡沫包装盒、冰箱外包装泡沫以及其他白色泡沫废料。

EPS造粒机结构

EPS造粒机设计简单高效,主要由主机、辅机、模头、粉碎机、冷却水箱等组成。

塑料发泡挤出机参数

以上只是舒利热销的EPS造粒机中的一部分,我们还有更多的型号和尺寸来满足不同客户对再生料的需求 EPS泡沫。我们的泡沫造粒机接受定制,如有需要请立即联系我们。

| 类型 | 产能(公斤/小时) | 电机(千瓦) |

| 220 (双减速机) | 150-175 | 15 |

| 270 (双减速机) | 200-225 | 18.5 |

| 220 (单减速机) | 150-175 | 15 |

| 270 (单减速机) | 200-225 | 18.5 |

| 320 (双减速机) | 275-300 | 18.5 |

| 350 (双减速机) | 325-375 | 22 |

塑料发泡挤出机的回收工艺

作为不可缺少的设备之一 塑料泡沫回收厂,EPS造粒机工作流程简单高效。首先,废旧塑料泡沫通过EPS泡沫破碎机进行破碎。然后将EPS泡沫填充到料斗中,由EPS造粒机主机熔化并挤出到辅机。二次塑化后,电动换网模头过滤杂质,进入冷池冷却,进入切粒机切割,得到均匀的EPS颗粒。

EPS泡沫造粒机的优点

- 投料口的设计考虑了不同物料的密度,客户可自行控制投料速度。温控箱可以让客户随时掌握EPS造粒机螺杆温度等工况,并根据面食的颜色进行调节,避免过热或熔化失败,同时也有助于制造更透明的颗粒。

- 主、副螺杆机筒均采用进口高强度优质碳素结构钢,坚固耐用。

- 采用主辅机生产,加热温度稳定,有效改善物料分子结构,增强透气性,显着提高颗粒质量。

- 专为独立使用而设计,也可与塑料泡沫破碎机、压实机等机器配合使用,形成高效 泡沫回收厂。此外,Shuliy 还提供在线安装说明和其他培训服务,以确保客户有效地使用其泡沫造粒机。

- 生产的颗粒用途广泛,市场供不应求。远销日本、韩国,受到用户的广泛好评。其机械性能稳定可靠,产量取决于设备的大小。

常问问题

什么是EPS造粒机?

EPS造粒机旨在回收废弃EPS产品或废弃EPS豆,生产可用于其他塑料应用的塑料颗粒。

我可以定制 EPS 颗粒尺寸吗?

是的,我们提供标准尺寸的 EPS 颗粒尺寸,但我们也可以接受定制的 EPS 颗粒尺寸。

我可以定制 EPS 颗粒的长度吗?

是的,EPS造粒机支持不同的EPS颗粒长度。

为什么EPS塑料颗粒的颜色与EPS造粒机的颜色不同?

这取决于废弃 EPS 产品的质量。更清洁的 EPS 废料可以生产出质量更高的 EPS 颗粒。

EPS颗粒经过造粒机后可以直接放入袋子中吗?

是的,EPS颗粒可以直接包装。

5