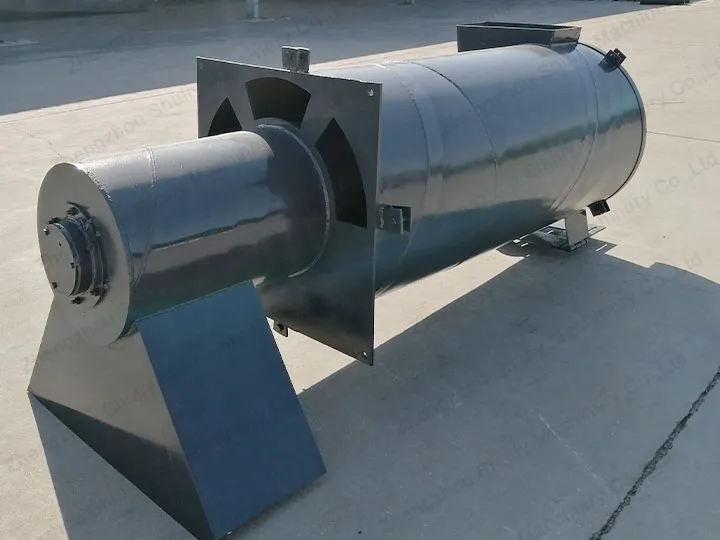

Our vertical type dewatering machine is a highly efficient and energy-saving dewatering equipment designed for the dewatering needs of various plastic raw materials. The equipment adopts advanced centrifugal dewatering technology, and rapidly separates and discharges water from plastic granules or fragments through high-speed rotation.

Application of Vertical Type Dewatering Machine

The vertical dewatering machine is a kind of equipment used to extract and dewater plastics automatically after crushing and cleaning. Its application scenarios vary in different plastic washing lines.

In a film washing line, a vertical centrifugal dryer is attached to the end of the washing tank. It can extract and dehydrate the washed film material directly. In this case, only the vertical type dewatering machine is required, as the film material can be pelletized in a watery state.

For the processing of hard materials, the vertical centrifugal dryer likewise starts with extraction and preliminary dewatering. However, since the hard material needs to be completely dry before subsequent processing, the vertical dewatering machine must be followed by a horizontal dryer to further dry the plastic.

Working Principle of Plastic Scrap Dryer Machine

The plastic scrap dryer machine consists of a high-speed rotor, enclosed by a removable screen. The wet material enters through the bottom inlet and is discharged from the top. At the center of the centrifugal dryer is a long shaft with many paddles, which is rotated by an electric motor at nearly 900-1500 revolutions per minute.

The centrifugal force generated by the high-speed rotation stirs up the material in the screen and brings out excess water. The water is then discharged through a perforated screen and a drain at the bottom, where it is collected for recycling. The airflow carries the plastic film out of the plastic scrap dryer machine.

Vertical Centrifugal Dryer Parameters

| Specifications | Instructions |

| Product | Vertical type dewatering machine |

| Model | SL-500, SL-600 |

| Power | 7.5KW, 15KW |

| Raw materials | Crushed and cleaned plastic sheets |

| Matching equipment | Plastic washing tank, horizontal dryer |

| Delivery date | 40-45 days |

| Warranty period | 1 year |

Welcome to contact our sales manager, our professional staff will recommend the most suitable machine model for you according to your needs.

Video of Vertical Centrifugal Dewatering Machine

Advantages of Plastic Dehydrator

- The whole selection of imported stainless steel materials is acid-resistant, alkali-resistant, corrosion-resistant; small footprint, reasonable design, beautiful and generous appearance.

- The blade is made of thickened stainless steel. The screen adopts stainless steel, which is easy to change. Automatic operation is simple, button control, safe and reliable, long service life.

- The moisture carried by the material is thrown off by centrifugal force instead of evaporation, so the drying efficiency is higher. Less power consumption, fast efficiency, and high automation procedures, greatly reduce labor intensity.

- Vertical type dewatering machines can be used with a variety of equipment before and after. Such as a rinsing tank or a horizontal dryer.

Related Film Washing Line

The vertical centrifugal dewatering machine is usually used in plastic film recycling lines, usually in combination with a rinsing tank, for a good drying effect and a wide range of materials.