The label removing machine is the first step in the PET bottle recycling line, the main function is to completely separate PET bottles from their surface labels and provide clean bottle raw materials for the subsequent recycling process. The machine is capable of efficiently processing PET bottles of various shapes and sizes, ensuring that the labels are completely separated from the bottles.

Plastic bottle label remover ensures the high purity and quality of recycled PET bottle flakes by efficiently removing bottle labels, reducing the content of impurities, improving the quality of recycled PET, and recycling efficiency during the PET bottle recycling process. The following video shows the application of this machine in PET bottle recycling.

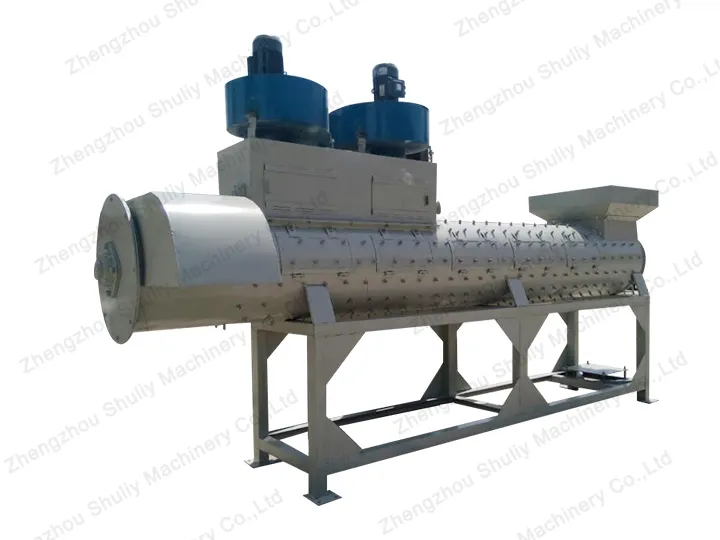

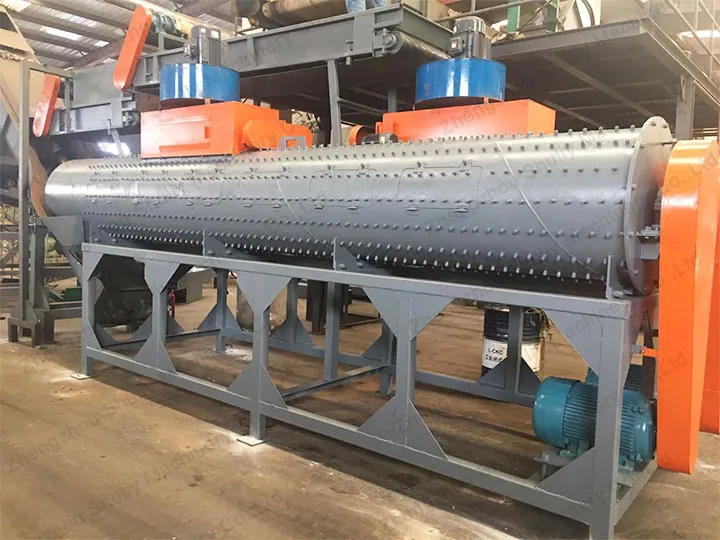

Shuliy’s PET Bottle Label Removing Machine

Our PET bottle label remover machine is a machine specially designed to remove labels from PET bottles. The machine adopts highly efficient mechanical separation technology to quickly and accurately remove labels from PET bottles.

For round bottle labels, the separation efficiency is as high as 98%-99%, while for flat bottle labels, the separation efficiency can reach 90%-93%. This efficient label removal technology ensures the purity and quality of PET bottle flakes in the subsequent recycling process.

If you are currently using the traditional method of recycling plastic bottles, we highly recommend adding label removing machine to increase the quality and capacity of your PET bottle washing plant. If you have any questions or customized needs about the plastic recycling machine, you can contact us at any time, there will be professional staff to answer you carefully.

Advantages of PET Bottle Label Remover

Efficient Label Removal: The PET bottle label removing machine removes labels from PET bottles with high efficiency. For round bottle labels, the separation efficiency is 98%-99%; for flat bottle labels, the separation efficiency is 90%-93%, which significantly improves the efficiency of the whole recycling process.

Enhance PET Bottle Flakes Quality: By removing bottle labels, the label remover machine can effectively reduce the PVC content to less than or equal to 100-300mg/kg, ensuring the purity and quality of the final PET bottle flakes. This is essential for the production of high-quality recycled PET material.

Easy to operate: the equipment is reasonably designed, easy to operate, easy to maintain, able to complete a large number of PET bottles in a short period to complete the task of de-labeling, and suitable for all sizes of recycling enterprises.

Role of PET Bottle Label Remover Machine

- Separate the PET bottle from the label paper.

- Preliminary work before crushing in PET production plant.

- To reduce the PVC content of PET net flakes.

- Greatly improve the efficiency of plastic bottle recycling plants and replace manual production.

PET Bottle Label Remover Processing Effect

Through advanced mechanical and process technology, the PET bottle label removing machine can ensure the complete separation of the label from the bottle. PET bottles treated by the de-labeling machine are changed from bottles with labels to bottles without labels, which greatly reduces the content of PVC and ensures the quality of the final PET bottle flakes. Below is a comparison chart of bottles before and after treatment, which can visualize the excellent effect of the plastic bottle label remover.

Working Principle of PET Bottle Label Remover

The working principle of the PET bottle label removing machine is mainly to remove the labels on PET bottles effectively by mechanical separation and friction. The following is the description of its specific working principle:

First, once the PET bottle enters the machine, it passes through a series of blades or scrapers that rotate at high speeds to physically rub and cut. These blades or scrapers are usually made of high-hardness materials that effectively separate the label from the bottle.

The detached label fragments are separated individually by a wind sorting system, while the bottle fragments move on to the next step in the process. Regarding the fan, usually, one fan is assigned to the production of one ton and below, and two fans are recommended for larger production to ensure the thoroughness of the de-labeling.

PET Label Remover Machine Video

Parameters of PET Bottle Label Remover Machine

| Model | SL-50 |

| Length (m) | 4.3 |

| Width (m) | 0.63 |

| Power (kW) | 15+1.5 |

| Label moving rate | 99% |

This is our hottest-selling model and we have many other models for you to choose from. If you are interested, please contact us and we will introduce you to the details of the de-labeling machine.

FAQ About Label Removing Machine

Does The Device Support Customization?

According to customer demand, the equipment can be properly customized to meet different production requirements and bottle specifications.

Can You Help Us If We Have A Problem With The Machine Or Production?

Yes, no problem. We offer preventive maintenance and after-sales service. We test label removing machines before delivery. We offer comprehensive maintenance options to prevent equipment problems from becoming a problem.

We also offer a one-year warranty. If there is a problem in use, you can tell us. Our engineers will do their best to help you solve the problem. Our engineers can come to your plastic recycling plant to help you solve the problem.

How Can I Get Prices, Photos, and Videos About The Machine?

You can contact me online or send an inquiry. Please be as clear as possible with the details of your request so that we can send you a price as soon as possible.

We can all receive WhatsApp, WeChat, phone calls, or other means to avoid any delays. After receiving your inquiry, our sales manager will contact you for the first time to provide you with all the detailed information about our PET bottle recycling machine, including pictures, videos, quotations, and so on.