¡Buenas noticias! La línea de lavado de película plástica de Shuliy ha sido enviada con éxito a Costa de Marfil. Durante esta cooperación, los clientes de Costa de Marfil están muy satisfechos y aprecian mucho los productos y servicios de Shuliy Machinery. Si deseas saber más sobre los productos y servicios de Shuliy, ¡por favor lee más información detallada sobre esta transacción!

Necesidades del cliente

Côte d’Ivoire, un país ubicado en África Occidental, tiene un rico recurso de película plástica desechada. Nuestro cliente, un reciclador de plástico experimentado, había comprado anteriormente equipos de pelletización en otro lugar.

Sin embargo, había una serie de problemas con su equipo existente que afectaban la producción y la calidad. Por lo tanto, estaba buscando un socio confiable que proporcionara un conjunto de línea de lavado de película plástica eficiente para expandir la capacidad de producción mientras evitaba los problemas anteriores.

¿Por qué eligió el cliente la línea de lavado de film plástico Shuliy?

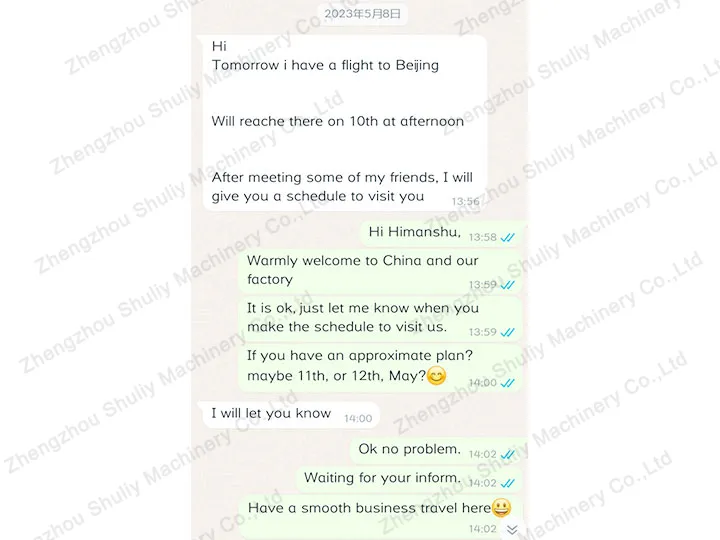

- Solución profesional: En el proceso de búsqueda de una solución, el cliente contactó a nuestra gerente de proyecto, Helen, quien no solo escuchó las preguntas del cliente, sino que también respondió a sus inquietudes de manera oportuna. Además, Helen compartió activamente el video de la fábrica y la información detallada del producto para mostrar al cliente el rendimiento superior de la línea de lavado de película plástica Shuliy.

- Máquina superior: Nuestras respuestas profesionales y comunicación atenta ganaron la confianza del cliente. El cliente decidió visitar la fábrica de Shuliy para tener una comprensión más completa del rendimiento y la calidad del producto. Después de la visita al sitio, el cliente mostró una alta satisfacción con la línea de lavado de película plástica de Shuliy.

Parámetros de la línea de granulación de reciclaje de plásticos

Los siguientes son los parámetros de esta línea de lavado de película plástica, toda la línea de peletización se puede personalizar según los requisitos de los clientes. Si tiene alguna pregunta, no dude en consultarnos.

| Máquina | Especificación |

| Cinta transportadora | Longitud: 5m Ancho: 1m Potencia: 2.2kw Con rodillo magnético |

| Trituradora de plástico | Modelo: SLSP-600 Potencia del motor: 30 kw Capacidad: 600-800kg/h 10 cuchillos Material de las cuchillas: 60Si2Mn |

| Potente máquina de limpieza de doble tanque y tubo de calefacción | Potencia del motor: 7.5kw Dimensiones: 5.0m*1.4m*1.6m Diámetro: 0.6m*2Cuchilla Grosor: 10mm Grosor de la pared exterior: 4mm Material: Q235 Potencia de calefacción: 60kw |

| máquina de desagüe de elevación | Potencia del motor: 7.5kw Dimensiones: 2.6m*0.7m Diámetro: 0.5m Peso: 450kg Grosor de la cuchilla: 6mm Grosor de la pared exterior: 4mm Material: Q235 |

| Tanque de lavado | Potencia del motor: 4kw Dimensiones: 4.5*1.2*1.3 Potencia del motorreductor: 1.5kw Peso: 1200kg Grosor de la cuchilla: 6mm Grosor de la pared exterior: 3mm Material: Q235 |

| Secador horizontal | Sequedad: 98% Potencia del motor: 15kw Dimensiones: 2.5m*1.0m Pantalla: hecha de acero inoxidable 304 Grosor de la cuchilla: 10mm Grosor del husillo: 8mm |

| máquina de peletizado de plástico | máquina de fabricación de pellets Host Modelo: SL-150 Potencia: 37kw 2.3 tornillo Método de calefacción: calefacción cerámica Reductor de engranaje endurecido segunda máquina de fabricación de pellets Modelo: SL-125 Potencia: 11kw Tornillo de 1.3m Método de calentamiento: calentamiento por anillo calefactor Reductor de engranaje endurecido Material del tornillo: 40Cr (Alta dureza y resistencia al desgaste) Material de la manga: acero No.45 tratado térmicamente Matriz hidráulica doble Potencia: 3KW (Cambiar máquina neta sin parar) |

| Enfriamiento tanque | Longitud: 3m Material: acero inoxidable |

| Máquina de corte de pellets | Regulación de velocidad del convertidor Potencia: 3kw cuchillos Hob |

| Contenedor de almacenamiento | Potencia: 2.2kw Un soplador de alta presión entrega los pellets y elimina el agua de los pellets. |

Línea de granulación de reciclaje de plástico enviada a Côte d'Ivoire