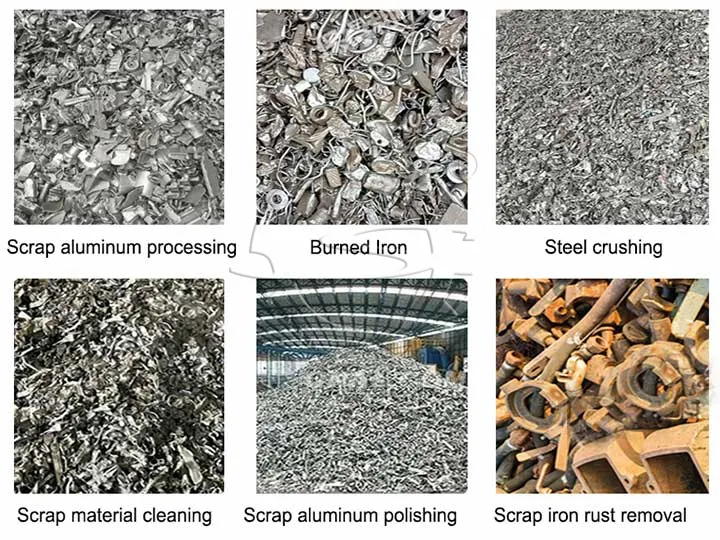

Rotary drum polishing machine is our drum-type metal dry grinding and polishing solution for batch surface finishing. Based on your needs for deburring, rust removal, edge rounding, and bright polishing, we configure and deliver systems for metals, burnt iron, crushed scrap, stainless steel, waste aluminum, oily parts, scrap steel, non-ferrous metals, and non-metallic parts, balancing throughput and surface quality.

Applications and Finishing Performance

This scrap metal polisher suits medium to large parts and is especially suitable for easily deformable workpieces. Finished parts retain their dimensional accuracy, with surface roughness improved by 1–2 grades, ready for assembly or pre-coating steps.

- Suitable materials: metals, burnt iron, crushed scrap, stainless steel, waste aluminum, oily parts, scrap steel, non-ferrous and non-metallic products

- Typical processes: deburring, rust removal, edge rounding, bright polishing

- Material size: oily or rusty items under 400 mm diameter (including scrap aluminum)

Rotary Drum Polishing Machine Working Principle and Process

A motor drives the drum via a reducer. Flow-guiding and turbulence liners inside the drum create a stable tumbling and cascading action. Materials and media (mineral sand) are fed by conveyor into the drum; continuous throwing, tumbling, friction, and mixing allow the media to absorb surface oil and rust, achieving degreasing, derusting, and polishing. This dry process is ideal for power-plant burnt-iron scrap and oily metal parts, reducing wet cleaning and drying demands.

Working Video of The Scrap Metal Polishing Machine

Key Structure and Features of Scrap Aluminum Polishing Machine

- Aperture gear: high-strength alloy, one-piece casting for higher stability and reliable operation

- Machine body: extra-thick steel plates with precision welding and finishing; wear-resistant, durable, and safe

- Hopper feeding: enlarged hopper for even feeding to avoid uneven output and stabilize batch quality

- Service and assurance: scheduled maintenance guidance, strict delivery and acceptance standards; supported by customer approvals

Build a Metal Crushing and Sorting Line (Broken-Bridge Aluminum Sorting Line)

This rotary drum polishing machine can be combined with a metal shredder, metal crusher, eddy current separator, and a dry grinder in sequence to form a complete metal crushing and sorting line, also known as a broken-bridge aluminum sorting line. Typical flow:

- Metal shredder: pre-shredding and volume reduction

- Metal crusher: further size reduction, can control the discharge size.

- Eddy current separator: efficient non-ferrous separation (aluminum, copper)

- Dry grinding/drum dry finishing: degreasing, derusting, deburring, and surface conditioning to improve sorting cleanliness

We size the equipment, media, and layout to your feed type (e.g., broken-bridge aluminum profiles, burnt-iron scrap, mixed Cu/Al), target purity, and throughput, ensuring stable recovery and controlled processing costs.

Contact Us For Details on Metal Recycling Equipment

As your supplier, we configure the right rotary drum polishing machine for your materials and process goals and can plan a full line including shredding, crushing, dry finishing, and eddy current sorting for broken-bridge aluminum applications. Share your samples and parameters, and we will provide a targeted proposal, quotation, and trial run.