O triturador de espuma horizontal é uma máquina eficiente e confiável projetada para processar e triturar uma ampla gama de materiais de espuma EPS. Com seu design compacto e operação fácil, a máquina é capaz de pulverizar rapidamente grandes pedaços de espuma EPS em pequenos pedaços uniformes. O tamanho das partículas de espuma EPS trituradas é significativamente reduzido, facilitando a granulação, bem como o armazenamento e o transporte.

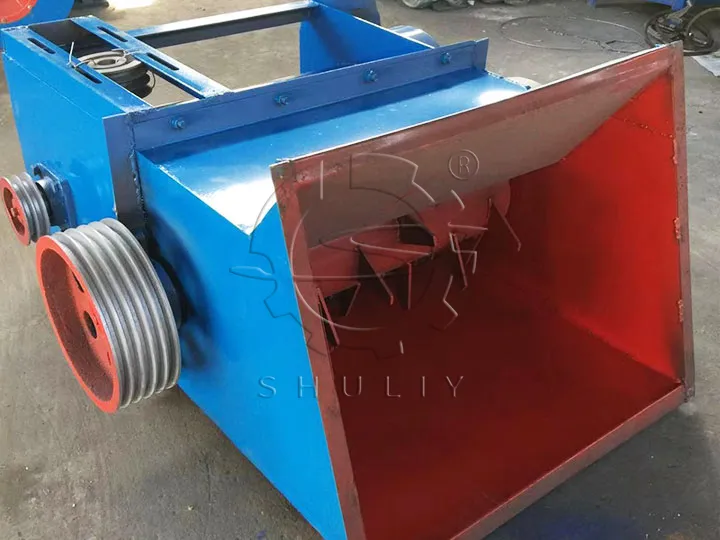

Triturador de Espuma Horizontal Shuliy

Nosso triturador de isopor adota lâminas de alta qualidade e um sistema de potência potente para garantir operação estável a longo prazo com baixos requisitos de manutenção. É amplamente utilizado em todos os tipos de estações de reciclagem, plantas de tratamento de resíduos e empresas de manufatura, fornecendo uma solução ideal para a reciclagem eficiente de materiais de espuma.

Se você quer saber se o triturador de espuma horizontal pode lidar com suas matérias-primas, continue lendo, as matérias-primas aplicáveis e a aplicação deste triturador de isopor são descritas a seguir. Ou você pode deixar uma mensagem diretamente em nosso site, nosso gerente de vendas profissional irá recomendar a máquina certa de acordo com suas matérias-primas e necessidades.

Materiais Brutos de Espuma EPS Aplicáveis

O triturador de espuma EPS é principalmente utilizado para processar vários tipos de materiais de espuma EPS, incluindo espuma de embalagem, resíduos de construção, utensílios descartáveis, caixas de isolamento térmico, entre outros. As matérias-primas podem ser grandes pedaços de espuma EPS ou fragmentos menores, que são triturados em partículas ou lascas pequenas e uniformes após serem processados pela máquina trituradora de isopor.

O volume do produto acabado triturado é significativamente reduzido, o que é conveniente para armazenamento e transporte, e também estabelece a base para o subsequente reprocessamento e reciclagem. Esses resíduos podem ser utilizados na produção de produtos de espuma EPS reciclada, realizando a reciclagem eficaz de recursos.

Como o Triturador de Isopor é Aplicado?

The horizontal foam crusher can be used with an EPS pelletizer for an efficient foam waste recycling process. By pulverizing these foam materials into small pieces, the pulverizer is ready for the subsequent recycling process. The crushed foam material can be fed directly into the EPS granulator for processing to produce high-quality recycled pellets for use in the manufacture of new products.

Características da Máquina Trituradora de Isopor

Transporte por Fluxo de Ar: Trituradores horizontais de espuma costumam vir equipados com um sistema de ventilador ou soprador que utiliza um fluxo de ar intenso para conduzir os fragmentos leves de espuma através de um tubo até o funil e para o extrusor de EPS.

Sistema de Condutor Contínuo: A trituradora de Styrofoam e a tubulação de condução costumam formar um sistema contínuo onde os fragmentos de espuma pulverizados podem ser conduzidos ao funil sem parar, mantendo toda a linha de produção funcionando sem problemas.

Trituramento de Alta Eficiência: A trituradora de espuma EPS é equipada com lâminas potentes, capazes de triturar rapidamente grandes peças de material de espuma em pedaços menores, melhorando a eficiência do processamento subsequente.

Componentes Básicos do Triturador de Espuma EPS

Funil: O ponto de entrada da espuma EPS onde o material é alimentado na trituradora de espuma EPS.

Câmara de corte: A área onde ocorre o processo de trituração, abrigando as lâminas ou facas rotativas que quebram a espuma.

Motor e sistema de acionamento: Alimenta a trituradora de espuma plástica, o motor geralmente varia de elétrico a hidráulico, dependendo do tamanho e dos requisitos da máquina.

Sistema de descarga: Normalmente transporte por fluxo de ar, a máquina costuma vir equipada com um sistema de ventilador ou soprador que utiliza um fluxo de ar poderoso para transportar pedaços leves de espuma através de um tubo até um funil.

Parâmetros do Triturador de Espuma Horizontal

| Tipo | Tamanho do contorno (mm) | Tamanho de entrada (mm) | Potência (KW) | Capacidade (KG/H) |

| 800 | 1250*1290*660 | 800*600 | 5.5 | 250-300 |

| 1000 | 1250*1530*660 | 1000*600 | 5.5 | 300-350 |

| 1200 | 1300*1730*700 | 1200*600 | 7.5 | 400-450 |

| 1500 | 1600*2200*800 | 1500*800 | 11 | 450-500 |

Acima estão nossos modelos de trituradores de espuma plástica mais vendidos. Se você tiver necessidades específicas de produção ou outros requisitos personalizados, sinta-se à vontade para entrar em contato conosco, e forneceremos soluções profissionais.