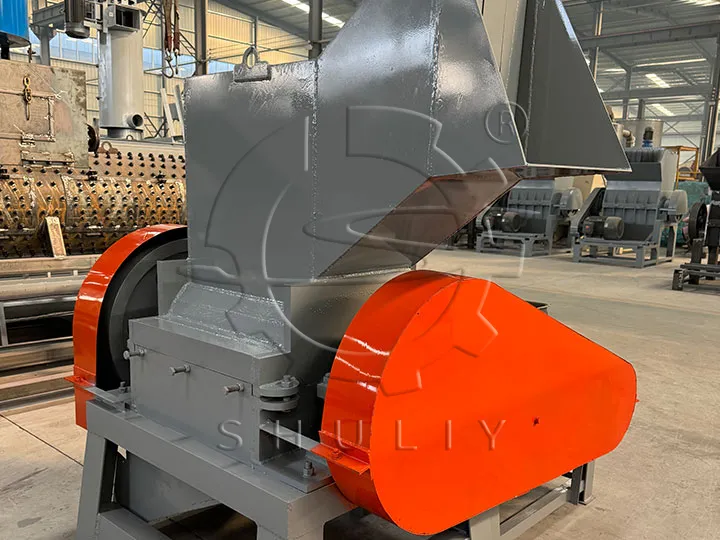

Im Prozess des Recyclings und der Wiederverwendung von Kunststoff spielt die Kunststoffschredder-Recyclingmaschine eine entscheidende Rolle. Ihre Zerkleinerungswirkung beeinflusst direkt die Qualität und Effizienz der Kunststoffverarbeitung. In diesem Papier werden wir die Faktoren diskutieren, die die Zerkleinerungswirkung von Maschinen zur Zerkleinerung von Abfallkunststoffen beeinflussen.

Einstellungen und Werkzeugkonfiguration für die Kunststoffschredder-Recyclingmaschine

- Maschineneinstellungen: Die Maschineneinstellungen der Kunststoffschredder-Recyclingmaschine haben einen direkten Einfluss auf den Zerkleinerungseffekt. Dazu gehören die Geschwindigkeit der Abfallkunststoff-Zerkleinerungsmaschine, die Größe der Einfüllöffnung und die Einstellung der Auslassöffnung. Angemessene Maschineneinstellungen können sicherstellen, dass der Kunststoff im Zerkleinerungsprozess gleichmäßig von der Kraft beeinflusst wird, um Überzerkleinerung oder Unterzerkleinerung zu vermeiden.

- Messeranordnung: Das Messer ist eines der Schlüsselkomponenten des Kunststoffschredders, und seine sinnvolle Anordnung bestimmt direkt die Zerkleinerungseffizienz. Die Anzahl, Form, Material und Anordnung von Kunststoffzerkleinerer-Klingen wird Auswirkungen auf die Zerkleinerungswirkung haben. Die geeignete Konfiguration der Messer kann das Plastik effektiv in die erforderliche Partikelgröße zerkleinern und die Effizienz der Wiederaufbereitung verbessern.

Eigenschaften von Kunststoffen

Die Beschaffenheit von Kunststoff ist ein weiterer wichtiger Faktor, der die Zerkleinerungswirkung von Recyclingmaschinen für Kunststoffschredder beeinflusst. Verschiedene Kunststoffe haben unterschiedliche Härte, Zähigkeit und Schmelzpunkt usw., daher ist es notwendig, die entsprechenden Zerkleinerungseinstellungen und Werkzeugkonfigurationen an ihre Eigenschaften anzupassen. Zum Beispiel benötigen härtere Kunststoffe möglicherweise einen leistungsstärkeren Zerkleinerer und verschleißfestere Messer für eine effektive Zerkleinerung.

Darüber hinaus wird die Form des Kunststoffs auch die Zerkleinerungswirkung beeinflussen, wie z.B. Folie, Block oder Faser usw. Es ist notwendig, eine angemessene Zerkleinerungsbehandlung entsprechend den verschiedenen Formen vorzunehmen, um sicherzustellen, dass die Zerkleinerungswirkung den Erwartungen entspricht.

Einstellung der Betriebsparameter

Die Einstellung der Betriebsparameter beeinflusst direkt die Betriebseffizienz des Kunststoffschredders. Dazu gehören Fressgeschwindigkeit, Zerkleinerungszeit, Zerkleinerungstemperatur und so weiter. Eine angemessene Einstellung der Betriebsparameter kann sicherstellen, dass der Kunststoff im Zerkleinerungsprozess der geeigneten Kraft ausgesetzt wird, um übermäßiges Zerkleinern oder unvollständiges Zerkleinern zu vermeiden.

Darüber hinaus sind das technische Niveau und die Erfahrung des Bedieners ebenfalls wichtige Faktoren, die die Einstellung der Betriebsparameter beeinflussen. Erfahrene Bediener können die Betriebsparameter rechtzeitig an die tatsächliche Situation anpassen, um den besten Zerkleinerungseffekt zu erzielen.