Our cardboard shredder machine is specifically designed to cut various types of corrugated cardboard into materials suitable for packaging fill, cushioning, or recycling. With a compact structure and user-friendly operation, the machine efficiently transforms waste cardboard into reusable resources—helping customers reduce costs and improve packaging efficiency.

With years of experience in waste paper processing equipment, we offer multiple blade combinations, customizable output styles, and plug/voltage options. We provide complete solutions tailored to your needs. Whether you run a startup e-commerce warehouse or a large-scale packaging and logistics company, we can recommend the right model and configuration for you.

Applicable Materials and Output Types

Our cardboard shredder is suitable for various types of corrugated and packaging cardboard, including:

- Waste cardboard boxes

- Corrugated board

- Trimmings and cut-off scraps

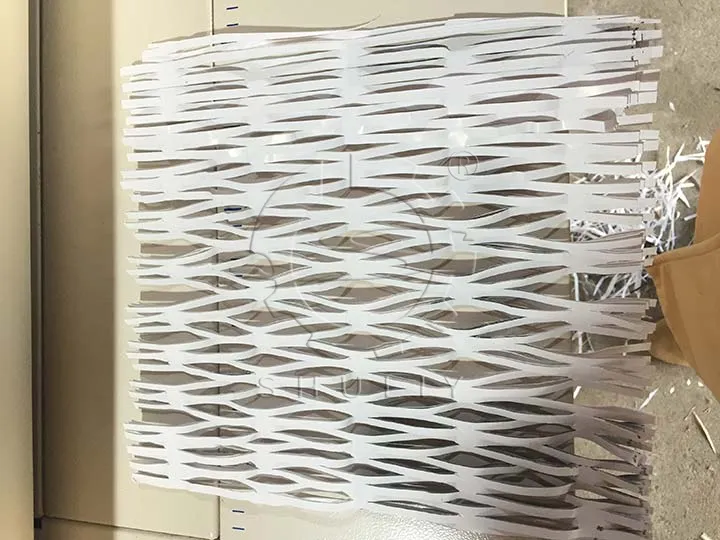

The cardboard shredder machine can produce different types of outputs depending on blade and screen configuration:

- Strip-shaped paper – for filling and wrapping

- Mesh-style expansion paper – for protective cushioning

- Flake-like paper scraps – suitable for baling or pulping

Output size can be adjusted by customizing the blade structure and screen design.

Versatile Uses of the Finished Output

The shredded cardboard has a wide range of applications across different industries:

- Packaging – as in-box filler for shock absorption and protection

- Logistics – as an eco-friendly replacement for plastic foam

- Recycling – as raw material for paper pulping and reuse

- Composting or bedding – for agricultural or animal care use

If you’re unsure which output type suits your needs, we’re happy to provide sample comparisons and suggestions.

Key Features and Advantages of the Cardboard Shredder Machine

Our cardboard box crusher offers several practical benefits:

Customizable Output and Blades: We support customization of blade shapes and sizes to meet various product requirements.

Cost-Effective:Helps reduce packaging material costs by replacing traditional fillers with shredded cardboard.

Customizable Plug: We can customize the plug and power configuration according to the customer’s local requirements, ensuring the machine is ready to use with no additional adapters needed.

High-Quality Blade Configuration: The cardboard shredder machine is equipped with high-strength blades made of 38CrMnAl alloy steel, offering excellent wear resistance and impact toughness. The blades have a long service life and require minimal maintenance, effectively reducing operating costs.

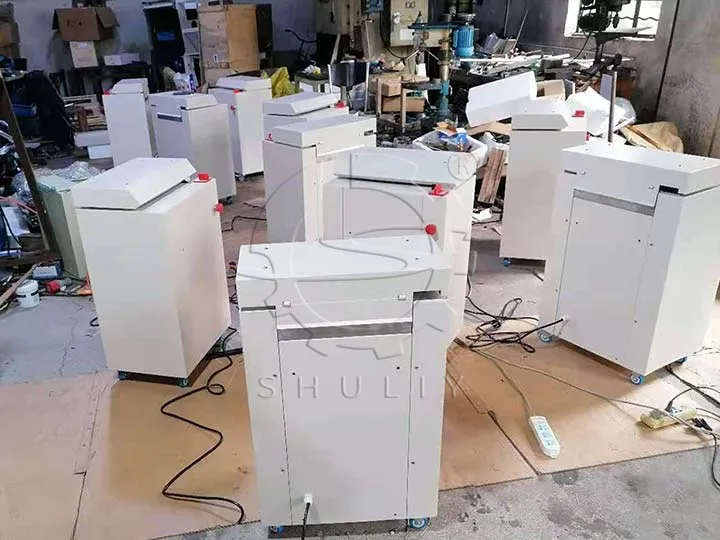

Industrial Cardboard Shredder for Sale

We offer two best-selling models of industrial cardboard shredder machines: SL-325 and SL-425, designed to meet different processing needs.

- The SL-325 model supports input materials up to 20mm thick and 325mm wide, ideal for shredding 3–5 layers of corrugated cardboard (equivalent to 20–40 sheets of A4 70g paper). It operates on 220V, 50Hz power supply.

- The SL-425 model accommodates materials up to 20mm thick and 425mm wide, suitable for 5–7 layers of corrugated cardboard (roughly 20–70 sheets of A4 70g paper), and is powered by 380V, 50Hz.

Common Customer Questions

In conversations with our clients, we often hear the following questions—perhaps you’re wondering the same:

What cardboard thickness can the machine handle?

Typically, it can process corrugated cardboard up to 20mm thick. We can customize stronger blades for thicker materials.

How long do the blades last?

Depending on usage frequency and the type of cardboard processed, a single blade can last 2 to 3 years and can be replaced individually when needed.

What power supply does it support?

We provide various voltage and plug options (e.g., 220V/380V) based on your country’s requirements.

How We Help You Choose the Right Model

If you’re unsure which cardboard shredder machine model fits your needs, simply share the following details with us:

- our estimated daily or hourly cardboard volume

- Desired output type (strips, mesh, flakes, etc.)

- On-site voltage and available space

- Final application of the shredded material

Based on this information, we’ll recommend the most suitable model, blade configuration, and provide a layout plan and quotation. If you’re interested in this equipment, feel free to contact us for technical details and a quote.