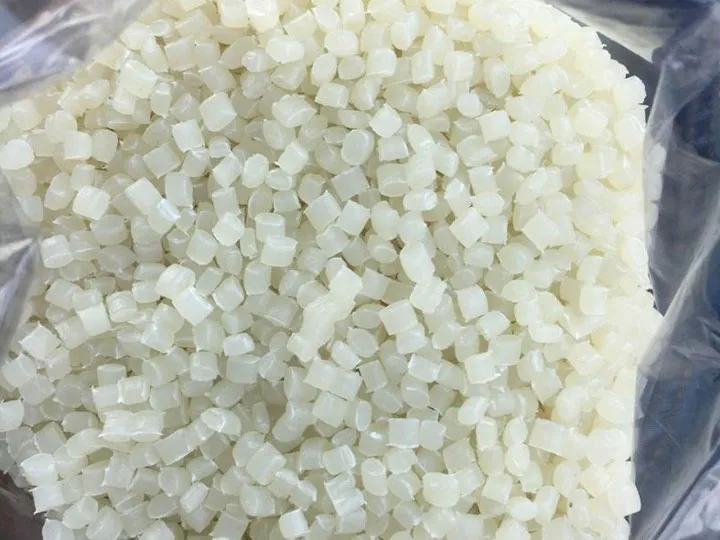

Plastic granule making machines play a key role in the recycling and reuse of plastics. However, some plastic materials are not suitable for mixing for granulation. PP and PE plastics, in particular, are not suitable for mixing due to the differences in their properties. This article looks at why these two plastics should not be pelletized together, and what the consequences of pelletizing them together might be.

Reasons for not pelletizing at the same time

Different physical properties

There are significant differences in the physical properties of PP and PE plastics; PP plastics are generally harder, while PE plastics are softer. This difference results in uneven distribution of heat and pressure generated during processing, which in turn affects the quality and properties of the pellets.

Melt temperature differences

There are also differences in the melt temperatures of PP and PE. PP melts at temperatures between 160°C and 170°C, whereas PE melts at temperatures between 120°C and 130°C. When these two plastics are pelletized together by plastic granule making machine, the melting temperature of the pellets can vary. When these two plastics are pelletized together, it isn’t easy to control the heating temperature due to the large difference in melting temperatures, which affects the effect of pelletizing.

Consequences of pelletizing together

Poor pellet quality

When hard PP plastics and soft PE plastics are mixed for pelletizing, the difference in their properties may result in poor pellet quality. These pellets may have uneven sizes, irregular shapes, etc., affecting subsequent processing and application.

Damaged plastic granule making machine

Plastic granule making machines usually need to be adjusted and set up for different types of plastics. If PP and PE are mixed for pelletizing, this may lead to machine damage or premature wear and tear, increasing equipment maintenance costs.

Reduced productivity

Productivity can also be affected due to quality issues and plastic granule making machine failures during the pelletizing process. More time and cost are required to repair or replace equipment, which reduces productivity.

In summary, there are significant differences between PP and PE plastics, so it is best not to mix them when performing plastic pellet manufacturing. Failure to do so can lead to a range of consequences including inconsistent pellet quality, equipment failure and end product performance issues. Therefore, when carrying out plastic recycling and reuse, plastics should be sorted and processed appropriately according to their type and nature to ensure the quality and sustainability of recycled plastics.