Our plastic bag shredder is a specialized equipment for processing and recycling waste plastic film. It cuts and crushes the plastic film into smaller particles using a high-speed rotating blade, thus facilitating subsequent recycling processes such as cleaning and granulation.

Equipped with a powerful motor and 60Si2Mn wear-resistant blades, this equipment can efficiently process a large amount of plastic film, and the size of the crushed particles can be adjusted according to the demand. Its output is 600-1200kg/h, which can meet the demand of large-scale production.

The video above is a working video of the plastic film shredder, which is equipped with a shredder fan as well as ducting to better facilitate material extraction and prevent clogging of lightweight plastic film.

In addition to the materials in the video, this machine can also handle more plastics such as woven bags. Please continue reading.

Raw Materials Of Plastic Bag Shredder

Plastic film shredders are suitable for processing a wide range of waste plastic films, including polyethylene (PE), polypropylene (PP), and other common plastic films. The raw materials for these films typically come from sources such as industrial packaging, agricultural mulch film, shopping bags, food packaging, and other sources.

Common materials include plastic bags, agricultural films, woven bags, tonnage bags, cement bags, etc. The plastic bag shredder can efficiently cut these raw materials into small particles, making it easier for the subsequent cleaning and pelletizing process.

Features of Waste Plastic Crushing Machine

Plastic film crushers have a variety of features to ensure efficient and flexible plastic film processing.

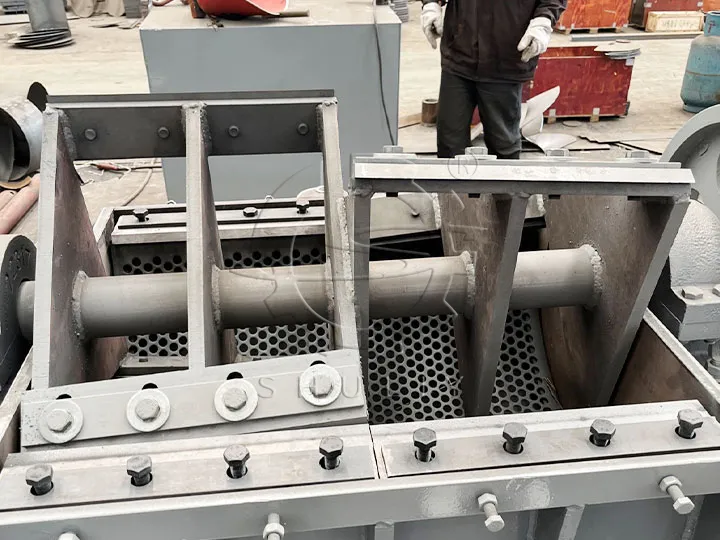

1, First of all, the gap between the fixed and moving knives of the shredder is adjustable, which enables the machine to be precisely adjusted to different materials of plastic film to ensure the best cutting effect.

2, The screen size of the plastic film crusher is between 40-50mm, which can be customized according to the specific needs of customers to meet different particle size requirements.

3, In terms of power mode, our plastic recycling crushers offer both motor and diesel options to suit different working environments and customer preferences.

4, To prevent the clogging of lightweight plastic film during processing, we can provide U-shaped pipes as well as blowers to effectively prevent material clogging problems.

5, In addition, customers can also choose to add water to the plastic bag shredder for wet shredding. This method not only increases the weight of the film material, making it easier to handle but also further cleans the plastic film during the crushing process and improves the quality of the recycled plastic.

Working Principle of Plastic Film Shredder

The working principle of a plastic bag shredder is roughly as follows: the material enters the crusher through the inlet and then enters the crushing area first. In the pulverizing area, several movable knives and fixed knives interact with each other to shear and crush the materials. The gap between the blades of the pulverizer can be adjusted according to the hardness and thickness of different materials to achieve the best pulverizing effect.

The crushed plastic film fragments are filtered through a screen. The aperture size of the screen can be adjusted as needed to control the particle size of the final product. Size-conforming pieces are conveyed through to the next process, while larger pieces continue to be sent back to the crushing area for reprocessing until the desired size criteria are met.

Recommended Plastic Film Pelletizing Line

Plastic bag shredders can be combined with other plastic recycling machines to form a complete production line, providing a more efficient and systematic recycling process. By combining the shredder with washing machines, dewatering machines, pelletizing machines, and other equipment, the entire recycling process becomes smoother and more efficient.

After the crushed plastic film pieces are cleaned and dewatered, they can go directly into the pelletizing process, ultimately producing high-quality recycled plastic pellets. This integrated recycling solution not only improves production efficiency but also ensures the quality of the final product and meets the diverse needs of customers.

Plastic Crusher Manufacturer

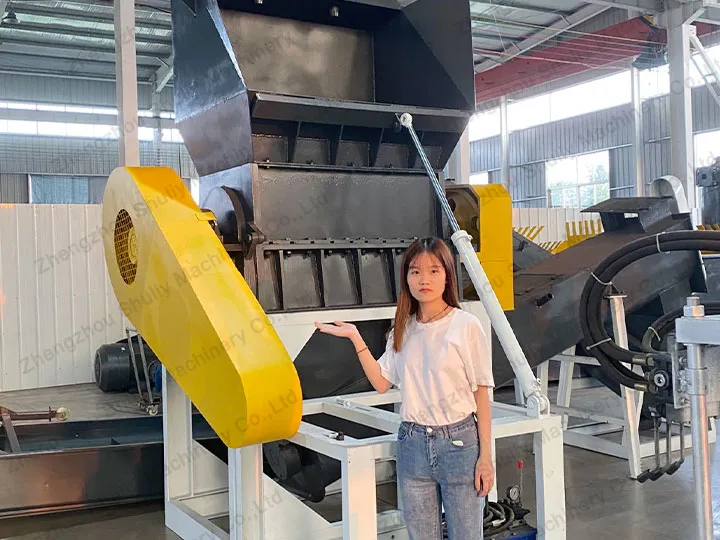

As a professional plastic shredder manufacturer, we are committed to providing comprehensive services and high-quality products to our customers. We offer a wide range of plastic bag shredders with various models, capacities, and appearances to meet various recycling needs. Our services include equipment design and customization to ensure that each shredder is perfectly adapted to the customer’s production line.

We also provide detailed product consultation to help customers determine the most suitable production capacity and configuration options. After the production of the equipment is completed, we are responsible for the transportation and installation of the equipment and provide comprehensive after-sales service to ensure that the customer’s equipment can run stably for a long time. Whether you need a single machine or a whole production line, we can provide you with the best solution.

Shuliy Plastic Bag Shredder For Sale

SL-1000 is one of Shuliy’s hottest-selling models of plastic bag shredder, with an output of up to 1,000-1,200 kilograms per hour and a power of up to 55 kW. The crushing chamber has 10 blades made of 60Si2Mn with a width of 1000 cm.

Shuliy plastic scrap shredders offer a wide range of models for plastic recycling projects of different sizes and needs. Each model is carefully designed to be efficient, durable, and easy to operate. Whether you’re working with plastic film, plastic bottles, plastic flakes, or a variety of plastic containers, Shuliy plastic shredders provide excellent pulverizing results.

If you are looking for an efficient and reliable plastic bag shredder, Shuliy is your first choice. We offer a wide range of plastic crushers to meet different production needs. Whether you are looking for small-scale production or high-volume processing, Shuliy offers customized solutions. Please contact us for more details on product specifications, pricing, and services.