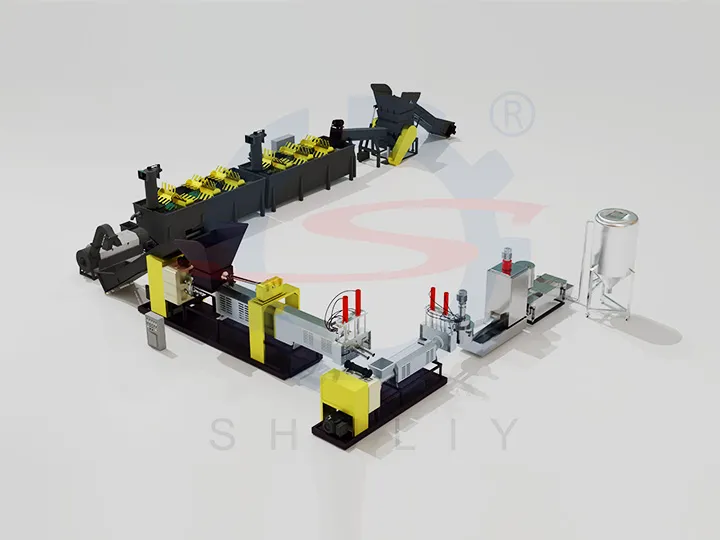

The plastic granule cutter is a kind of equipment used to cut the molten plastic material into uniform pellets. In the plastic recycling and pelletizing process, the plastic material is melted and extruded and then enters the cutting machine for cutting.

The pellet cutting machine cuts the continuously extruded plastic strip into small pellets using a high-speed rotating blade, ensuring consistent pellet size. Plastic pellet cutting machine usually has the advantages of high automation, simple operation, and high production efficiency. It is widely used in various pelletizing lines, providing high-quality raw materials for subsequent plastic processing.

Introduction of Plastic Granule Cutter

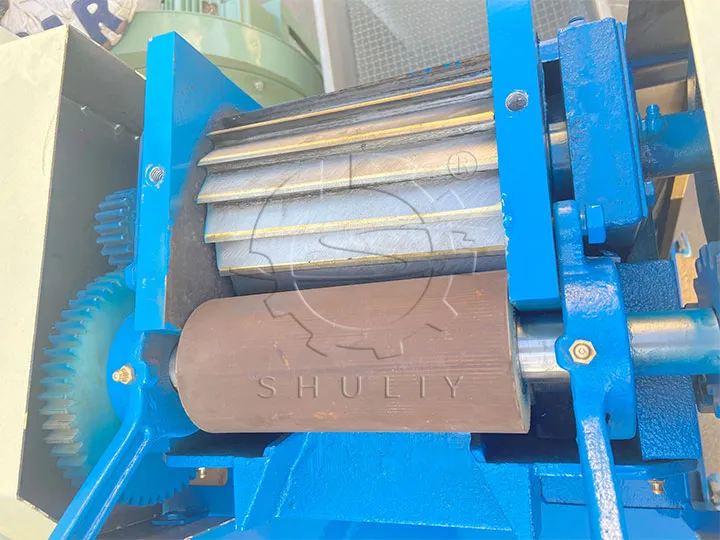

Our plastic pellet cutting machines are suitable for all types of plastic materials, including PE, PP, PVC, PET, and more. The machine utilizes a hobbing blade, which can accurately cut the molten plastic material into uniform pellets, ensuring that the quality and size of each pellet are consistent. The pellet size can be adjusted according to the customer’s demand to ensure that it meets the customer’s production needs.

Owing to our comprehensive industry expertise, we can manufacture and supply the best quality plastic granule cutter. Our state-of-the-art manufacturing facility designs these machines using the finest quality materials and high-tech machinery. In addition, the plastic granule cutter offered by us is manufactured as per the established quality guidelines to ensure that it complies with international quality.

If there are any customization needs also feel free to contact us, our professional sales managers will discuss the options with you and give you the best quote.

Application of Plastic Pellet Cutting Machine

Plastic pellet cutting machine is widely used in various extruder plastic pelletizing lines. The equipment is capable of accurately cutting molten plastic materials into uniform pellets, which is a key link in the plastic pelletizing process.

Whether it is processing waste plastic products or recycling plastic trimmings, the plastic granule cutter can efficiently complete the task and ensure the consistent quality of the pellets produced. It is suitable for a wide range of plastic materials, including PE, PP, PVC, PET, etc. It is widely used in plastic recycling enterprises as well as in all kinds of recycled plastic production projects.

Working Principle of Plastic Strip Cutting Machine

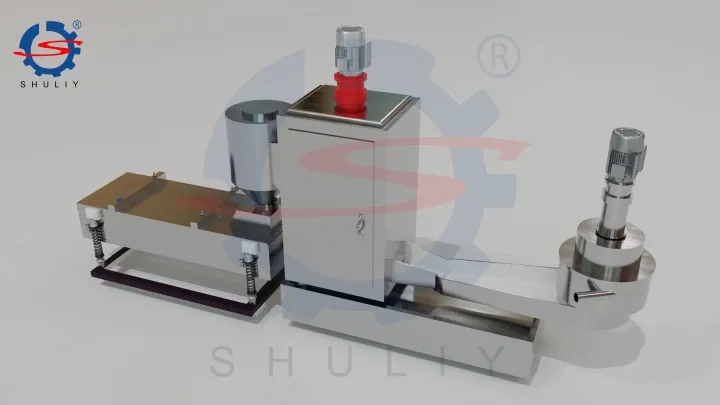

Our plastic pellet cutter is used to cut long plastic strips extruded from a plastic pelletizer into uniformly sized pellets. The principle of operation is as follows: First, molten plastic is extruded from the die head of the pelletizer to form continuous plastic strips, which are transported to the feed opening of the cutting machine. Then, the feed rollers of the cutting machine feed the plastic strips evenly into the cutting zone. In the cutting zone, carbide-tipped rollers cut the plastic strips into pellets.

Plastic Dana Cutter Machine Parameters

Below are the basic specifications of our best-selling plastic cutting machines. Our plastic granule cutters can be customized to meet your specific needs, leave a message on our official website or contact us directly with your material type and specific requirements and Shuliy will be happy to support you in choosing the model that best suits your production needs.

| Model | Power(kW) | Width of knives(mm) | Type of knives |

| SL-180 | 3 | 180 | Hob |

| SL-220 | 5.5 | 220 | Hob |

| SL-260 | 5.5 | 260 | Hob |

Features of Plastic Granules Cutting Machine

- The size of the pellets cut by the plastic granule cutter is about 3mm, which can be adjusted according to the customer’s requirements.

- The machine adopts a hard alloy hob, which is extremely durable, and the blade needs to be replaced only once for every about 2000 tons of pellets processed, thus realizing efficient production.

- The model of the plastic Dana cutter is determined by the length of the knife, i.e. the width of the left and right side, to meet different production requirements.

- We also provide a water ring cutting machine. Water ring cutting is more suitable for materials with poor flowability, such as plastic drums. We will recommend the right equipment according to your raw material and your specific needs.

Plastic Granule Cutter Usage Precautions

- Regular inspection of knives: The sharpness of knives directly affects cutting efficiency and product quality. You must check the tool’s wear regularly and replace or sharpen the tool in time to ensure the cutting effect.

- Keep the equipment clean: The equipment should be kept clean, especially in the cutting area and feeding system, to prevent impurities from entering and affecting cutting quality and equipment operation.

- Lubrication maintenance: regularly add lubricant to the transmission system and moving parts to reduce wear and prolong the service life of the equipment.

- Screening: A screening device can be installed behind the pellet cutting machine to separate granules of uneven size, ensuring that the final product pellets are uniform and consistent.

Plastic Cutter Machines Exported Cases

Plastic Granule Cutter Exported To Togo

A customer from Togo recently purchased a plastic pellet cutting machine and other plastic recycling equipment manufactured by Shuliy and visited the factory in person for a site visit. The customer showed great interest in the performance and operational effectiveness of these plastic recycling machines and was given a detailed understanding of the machine’s operating procedures and production process in the factory.

Plastic Pelletizing Machine Shipped to Botswana

A customer from Botswana wanted to build a local plastic recycling plant, so he purchased plastic recycling equipment from Shuliy, such as a plastic Dana cutter, plastic pelletizer, etc. Shuliy’s staff patiently answered the customer’s various questions and provided a comprehensive solution for the customer.

Plastic Cutter Machine Price

Shuliy, as a professional plastic recycling machinery manufacturer, is committed to providing efficient and reliable Plastic granule cutters. Prices vary by model, configuration, and capacity to meet the needs of different customers. By contacting the Shuliy team, you can obtain detailed product information and a personalized quotation package to ensure that the plastic Dana cutter you choose is perfectly suited to your production needs.