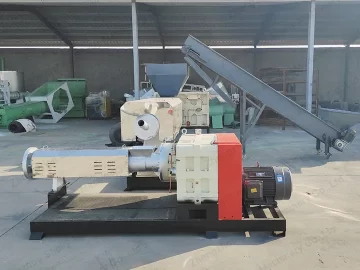

Plastic pelletizer machine price is one of the most important indicators that buyers are concerned about, and plastic granulator is one of the indispensable types of equipment in plastic film recycling line.

When choosing the right PP pelletizing machine, it is crucial to understand what factors influence plastic pelletizer machine price in order to optimize the purchasing strategy and save costs. In this article, we will highlight 5 key factors that affect plastic pelletizer machine price.

Equipment capacity affects plastic pelletizer machine price

Plastic pelletizer machine price is closely related to its equipment specifications and capacity. Generally speaking, the higher the capacity and the higher the specification, the higher the price of the plastic pelletizer. High-capacity machines can complete the production process of plastic pellets more quickly, so the price is relatively high.

When choosing a machine, buyers need to reasonably choose the equipment specifications and capacity according to their own production needs, and avoid purchasing a machine that is too expensive or insufficient to meet production needs.

Power and energy consumption

The power and energy consumption of a PP pelletizing machine can also have a direct impact on its price. Machines with higher power are usually able to handle larger quantities of plastic raw materials, but their energy consumption is correspondingly higher.

Buyers need to consider the balance between power and energy consumption according to their own factory’s power consumption and economic strength and choose granulator plastic recycling that meets their actual needs.

Degree of automation

With the progress of science and technology, the degree of automation of modern PE pelletizing machine is getting higher and higher. Automation features can reduce the need for manual operation and improve production efficiency and product quality.

As a result, PE pelletizing machines with more automation features are usually more expensive. Buyers can choose the right granulator plastic recycling based on the complexity of the production process and automation requirements.

Brand and Quality

The brand and quality of the plastic pelletizer are also important factors affecting plastic pelletizer machine price. PE pelletizing machines of well-known brands usually have more stable and reliable performance as well as longer service life. Although the price of these branded machines is higher, their excellent performance and after-sales service can bring more real value to the buyers.

In contrast, some lesser-known or lower-quality branded granulator plastic recycling may be less expensive, but they are prone to malfunction during use, and maintenance costs and production losses may increase.

Shuliy plastic pelletizing machine with good price and high production efficiency. If interested, feel free to contact us and our business manager will patiently answer any questions you may have.

Material and process used

The materials and processes used in the manufacture of plastic pelletizing machines also affect plastic pelletizer machine price. Some high-performance materials and precise machining processes can improve the durability and stability of granulator plastic recycling, but they will also increase the production cost, which will increase the plastic pelletizer machine price.

Buyers need to compare different materials and the processes of granulator plastic recycling and make a choice according to the actual situation.

In short, when choosing the right granulator plastic recycling, buyers should focus on the comprehensive consideration of factors such as equipment specifications and capacity, brand and quality, power and energy consumption, degree of automation, as well as materials and processes used.

Through a reasonable purchasing strategy, buyers can find the most cost-effective granulator plastic recycling, and realize the improvement of production efficiency and cost savings, so as to gain a greater advantage in the fierce market competition.