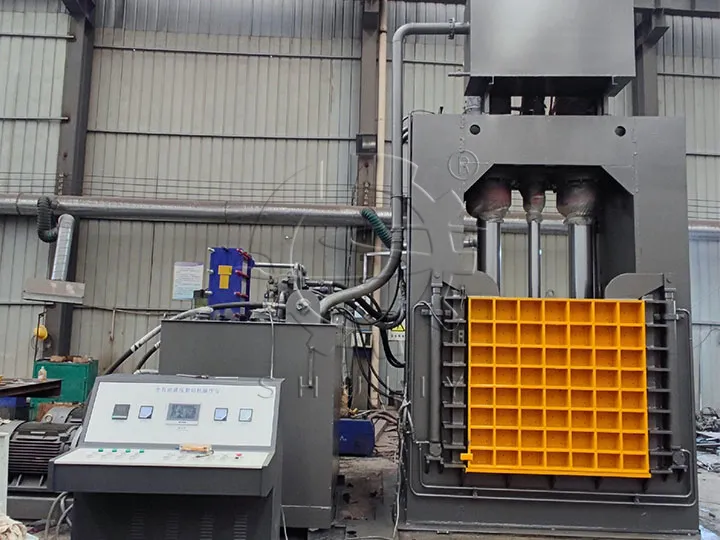

Our heavy-duty hydraulic scrap metal shear is the premier shearing solution, engineered for the demanding environments of modern scrap metal recycling centers, steel mills, and large-scale scrap yards. This core piece of scrap processing equipment powerfully and rapidly cuts oversized and bulky scrap metal into uniform, high-density, furnace-ready pieces, fundamentally boosting your operational efficiency and material value.

Our gantry shears are engineered to process a wide range of materials with ease. The most common applications for our clients include shearing end-of-life vehicles (ELVs), heavy melting scrap (HMS) such as I-beams, H-beams, and rails, large-diameter pipes, steel plates, and mixed light iron.

To meet diverse processing requirements, we, as a leading gantry shear manufacturer, offer a full range of models with shearing forces from 630 and 800 tons up to 1500 and 2000 tons, and beyond. Key specifications are customizable, allowing you to select the ideal charging box size (e.g., 6m to 8m in length), blade width (1600mm to 2500mm), and motor power configuration to match your specific throughput and material types. Every machine comes standard with an advanced PLC automatic control system and a wireless remote control, ensuring maximum operational safety, ease of use, and ultimate productivity.

What is a Gantry Shear?

A gantry shear for scrap metal, also known as a scrap metal shear, is a large-scale piece of scrap processing equipment designed for cutting and shearing heavy and bulky ferrous and non-ferrous scrap metal into smaller, more manageable, and denser pieces.

Its name derives from its distinctive “gantry” or bridge-like structure, which houses a powerful hydraulic shearing mechanism. Unlike smaller alligator shears, a gantry shear is built for continuous, automated processing of significant volumes, making it a cornerstone of modern metal recycling machines.

Key Components:

- Loading Box/Chamber: Where scrap material is initially placed.

- Compression System: A hold-down clamp or side-press walls that compact the material before cutting.

- Hydraulic Shear Head: The powerful cutting blade driven by a high-pressure hydraulic system.

- Conveyor System: For feeding material into the box and discharging the processed scrap.

How Does a Scrap Metal Shear Work?

- Feeding: Scrap metal is loaded into the feeding chamber, typically using a grapple crane or a feeding conveyor.

- Compression: The material is pushed forward into the shearing area. A hydraulic hold-down clamp or side compression box then firmly secures and compacts the scrap. This step is crucial for ensuring a clean, efficient cut and increasing the density of the material.

- Shearing: The powerful main shear cylinder actuates the cutting blade, which descends with immense force (often ranging from 600 to over 2000 tons) to cut the compacted scrap into a pre-set length.

- Discharge: The cut, densified scrap is then discharged from the machine, typically onto a conveyor belt, ready for transport, further processing, or direct furnace charging.

Scrap Metal Shear Working Video

Key Advantages: Why Invest in a Gantry Shear for Scrap Metal?

Investing in a heavy-duty scrap metal shear offers tangible benefits that directly impact your bottom line and operational efficiency.

- High Throughput and Productivity: Capable of processing many tons of scrap per hour, a gantry shear dramatically increases your facility’s processing capacity compared to manual torching or smaller shears.

- Powerful Cutting Capabilities: Easily handles difficult materials that other equipment cannot, including I-beams, H-beams, pipes, plates, car bodies, and mixed heavy scrap.

- Increased Material Density: The compression and shearing process produces dense, furnace-ready scrap pieces. This not only makes transportation more cost-effective but also improves melting efficiency in steel mills.

- Enhanced Safety and Reduced Labor: Automated cycles and remote operation capabilities minimize the need for manual handling of heavy scrap, significantly reducing workplace hazards and labor costs.

- Robust Construction for Longevity: Our gantry shears are built with high-strength steel frames and premium hydraulic components to withstand the harsh conditions of a scrap yard, ensuring reliability and a long service life.

Common Applications: Who Uses Hydraulic Gantry Shear?

Scrap metal shears are vital for a range of industries that handle large volumes of metal scrap.

- Scrap Metal Recycling Yards: The primary users, for processing incoming mixed and heavy scrap into a saleable, high-density product.

- Steel Mills: For pre-processing scrap before it enters the furnace, ensuring uniform size and density for optimal melting.

- Automobile Dismantling Facilities (ELV Processing): Ideal for efficiently cutting down flattened car bodies and chassis.

- Shipbreaking Yards: For sectioning large pieces of ship hulls and superstructures.

- Large-Scale Manufacturing Facilities: For processing industrial scrap generated during production.

How to Choose the Right Gantry Shear for Scrap Metal?

Selecting the correct model is critical for maximizing your return on investment. As your manufacturing partner, we can help you evaluate the following specifications based on your unique needs:

- Shearing Force (Tonnage): The most critical factor. It determines the thickness and type of material you can cut.

- Blade Length: A longer blade can process wider material in a single stroke.

- Chamber/Box Size: This dictates the maximum size of the scrap material you can load into the machine.

- Production Rate (Tons/Hour): Must align with your facility’s current and future processing volume requirements.

- Power Unit and Hydraulic System: The quality and design of the hydraulic system directly impact the machine’s performance, reliability, and energy efficiency.

Scrap Metal Shear Technical Specifications

Our hydraulic gantry shears are engineered from the ground up for durability and high performance in heavy-duty applications. Every machine is constructed with a high-strength steel frame, premium wear-resistant blades, and a stable, reliable hydraulic system. For our heavy-duty models, we incorporate advanced features like cast steel shear heads, a three-sided guide rail design, and an automatic lubrication system to ensure smooth, stable operation and minimize wear, even during continuous, high-intensity work.

To precisely match the diverse scrap processing needs of our global clients, we offer extensive customization options. Our product line spans from standard models with 630 and 800 tons of shearing force to heavy-duty units offering 1500, 2000 tons, and beyond. Key technical specifications can be configured to your requirements, including:

- Shearing Force: From 630 to over 2000 tons, capable of cutting materials of various thicknesses and tensile strengths.

- Charging Box Size: Lengths from 6 to 8 meters (or longer), with customizable width and height to accommodate your specific loading methods and scrap dimensions.

- Feeding Method: Depending on your throughput and material type, options include a highly efficient chain conveyor feeding system or a more powerful hydraulic cylinder pusher.

- Power System: Total motor power ranges from 135kW to over 425kW, paired with corresponding hydraulic pump assemblies to ensure robust power output.

- Cooling System: Choose between a forced-air cooling system or an industrial water-cooling system (ideal for high-power models) to maintain optimal hydraulic fluid temperature during continuous operation.

Our goal is to deliver a shearing solution that is perfectly tailored to your operational conditions and offers the best possible cost-effectiveness.

Related Metal Recycling Equipment

In addition to our heavy-duty scrap metal shears, we manufacture other key equipment to complete your metal recycling workflow:

- Hydraulic Metal Balers:Efficiently compresses aluminium cans, tin, metal shavings, trimmings and other waste materials into high-density briquettes to save transport and storage costs.

- Dual-Shaft Metal Shredders: It is specialized in handling large volume materials such as end-of-life car shells, waste home appliances, paint buckets, etc., shredding them into small pieces for subsequent sorting and processing.

Shuliy Machinery: Your Partner for Advanced Scrap Processing Solutions

A scrap metal shear for scrap metal is more than just a machine; it is a strategic investment in the productivity, safety, and profitability of your recycling operation. By automating the processing of heavy and oversized scrap, it transforms a bottleneck into a streamlined, value-adding process.

As a leading gantry shear manufacturer, we are committed to providing robust, reliable, and technologically advanced equipment tailored to your specific operational challenges. Our team of technical experts is ready to discuss your requirements and help you select the perfect shearing solution to drive your business forward.

Contact us today to request a quote or to speak with an expert about your scrap processing needs.