Пластиковая поплавковая мойка является одной из наиболее важных моечных машин на линии по переработке ПЭТ-бутылок, и ее основная функция заключается в эффективном отделении хлопьев ПЭТ-бутылок от этикеток и крышек. Это оборудование обеспечивает чистоту и качество хлопьев ПЭТ-бутылок за счет принципа поплавковой сепарации.

В ходе процесса хлопья ПЭТ-бутылок тонут из-за своей высокой плотности, а более легкие этикетки и крышки плавают на поверхности воды, обеспечивая тем самым эффективное разделение. Использование этого оборудования значительно улучшает качество конечных хлопьев переработанных ПЭТ-бутылок и гарантирует их пригодность для различных применений по переработке.

Принцип работы пластикового резервуара для поплавковой мойки

Используя воду в качестве среды, в соответствии с различной плотностью воды, пластиковый поплавковый резервуар может легко отделить хлопья ПЭТ и другие материалы, а также очистить хлопья ПЭТ.

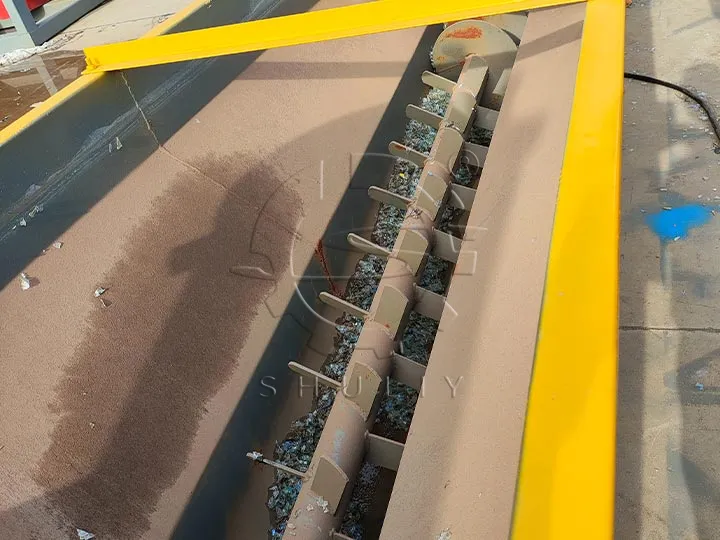

В ходе процесса хлопья ПЭТ-бутылок будут тонуть из-за своей высокой плотности, а более легкие этикетки и крышки будут плавать на поверхности воды. Машина оснащена винтовым конвейером в нижней части машины для транспортировки тонущих хлопьев ПЭТ-бутылок со дна промывочного бака на следующий процесс. Такая конструкция обеспечивает эффективное отделение хлопьев ПЭТ от других примесей, тем самым улучшая чистоту и качество переработанных хлопьев ПЭТ.

Преимущества разделения пластика поплавка в раковине

- Эффективное разделение: благодаря принципу плавающего и тонущего разделения он может эффективно отделять хлопья ПЭТ-бутылок от этикеток, крышек и других примесей, обеспечивая чистоту хлопьев ПЭТ-бутылок.

- Контроль качества: контролируйте содержание полиолефина на уровне ≤200–300 мг/кг, что значительно улучшает качество переработанных хлопьев из ПЭТ-бутылок.

- Автоматический конвейер: оснащен винтовым конвейером, автоматически транспортирующим хлопья ПЭТ-бутылок на следующий процесс.

- Гибкая настройка: его можно гибко регулировать в зависимости от производительности обработки и содержания примесей, адаптируясь к различным производственным потребностям.

Параметры резервуара для разделения поплавков

Возьмем, к примеру, параметры моечного бака линии мойки производительностью 1000 кг/ч.

- Напряжение: 380 В, 50 Гц, 3-фазное электричество.

- Мощность: 3кВт

- Толщина внешней стенки: 4 мм.

- Толщина лезвия: 6 мм

- Размер оборудования: 5000*1000*1000 мм

- Контроль содержания полиолефинов≤200-300 (мг/кг)

Количество конфигураций разделительных баков с поплавком

Обычно для линий мойки ПЭТ-бутылок производительностью до 1000 кг/ч мы рекомендуем оборудовать 1 или 2 сепараторных бака. Первый используется для первичного отделения примесей, а второй может быть установлен за баком горячей промывки для очистки выносимого из машины щелока.

На линиях по переработке ПЭТ производительностью 1000 кг/ч и выше можно установить три пластиковых поплавковых бака. За машиной для горячей промывки хлопьев ПЭТ установлены два сепарационных резервуара для обеспечения дальнейшего эффекта очистки и контроля кислотности раствора во время процесса очистки, чтобы значение pH поддерживалось на уровне ≤ 8,0. Такая конфигурация не только повышает эффективность очистки, но и эффективно улучшает качество конечных регенерированных хлопьев из ПЭТ-бутылок.

Дисплей стиральной машины для пластиковой стружки

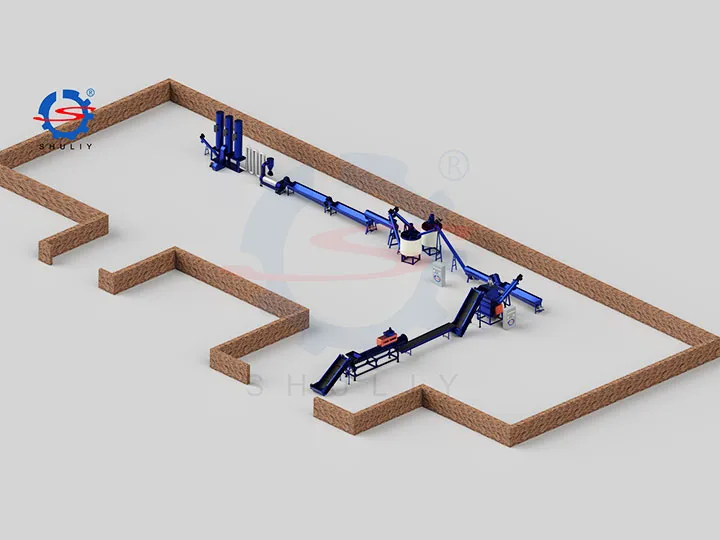

Рекомендуемая машина для переработки ПЭТ-бутылок

Сепаратор пластиковых отходов в флоат-танках для раковины работает совместно с машиной для удаления пластиковых этикеток, дробилкой для ПЭТ-бутылок, горизонтальной сушилкой и другим оборудованием для создания полноценного комплексного оборудования. завод по переработке пластиковых бутылок который эффективно перерабатывает отходы пластиковых бутылок в возобновляемые хлопья из ПЭТ-бутылок.

Его эффективная очищающая и разделяющая способность значительно повышает эффективность и производительность завода по переработке отходов. Таким образом, пластиковый поплавковый бак стал незаменимым оборудованием на заводе по переработке ПЭТ-бутылок, обеспечивая надежную техническую поддержку и гарантию на переработку пластиковых бутылок.