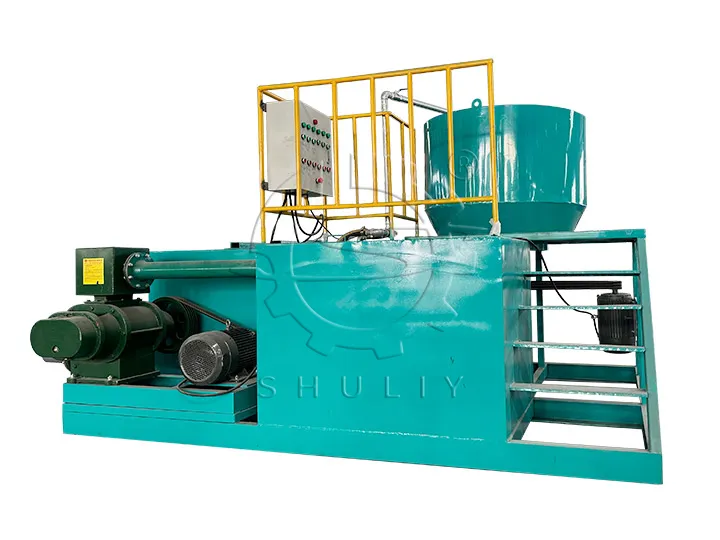

The egg tray paper pulping machine is an essential piece of equipment in the paper pulp molding industry. It is the first step in the egg tray production line, responsible for turning waste paper into pulp for molding. With simple operation and reliable performance, this machine is widely used in the production of egg trays, fruit trays, shoe supports, and other molded paper products.

Raw Materials of The Hydrapulper

This machine is designed to process various types of waste paper, including:

- Old newspapers (ONP)

- Cardboard

- Book paper

- Carton paper

- Waste office paper

These raw materials are inexpensive and easy to source, making the production process economical and environmentally friendly.

Working Principle of Paper Pulping Machine

The paper pulping machine uses mechanical force to break down the waste paper into pulp. The process typically involves the following steps:

- Loading waste paper and water into the pulping tank.

- The high-speed rotor or beater stirs the mixture, breaking down the paper fibers through continuous shearing and friction.

- The resulting pulp is filtered and pumped into the storage tank or transferred to the next stage of the egg tray production line.

The final pulp should be uniform and free from large debris, ready for molding into egg trays or other paper products.

Improve Egg Tray Quality from the Pulping Process

In egg tray production, the quality of the pulp directly affects the strength, thickness, and surface smoothness of the final product. To improve overall egg tray quality, the pulping process can be optimized in the following ways:

- Use clean raw materials: Select waste paper free from oil stains or plastic contaminants, such as newspapers, book paper, and corrugated cardboard, to ensure higher fiber purity.

- Control the water-to-paper ratio: A proper ratio helps maintain suitable pulp concentration, allowing fibers to distribute evenly and preventing thickness inconsistencies during molding.

- Extend pulping time: Thorough pulping allows the paper fibers to break down completely, resulting in stronger bonding and denser finished products.

- Add appropriate additives: Adding eco-friendly binders or strength enhancers can improve the egg trays’ compression resistance and moisture resistance.

By applying these methods, the physical performance and consistency of egg trays can be significantly improved, laying a solid foundation for the molding and drying stages.

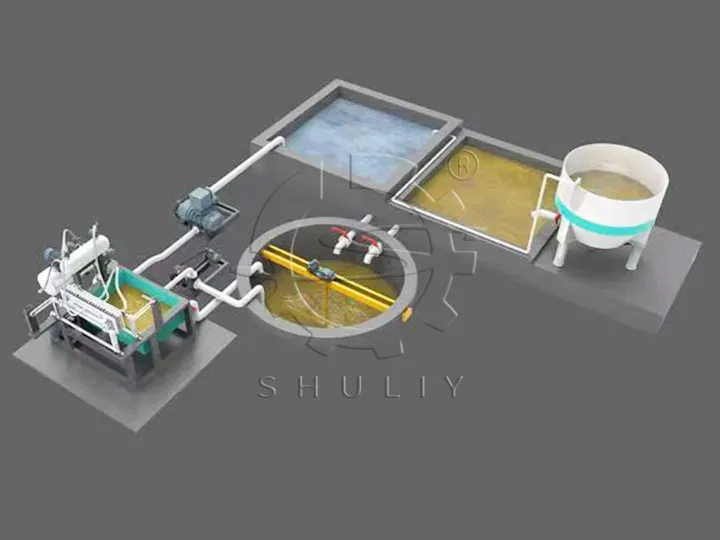

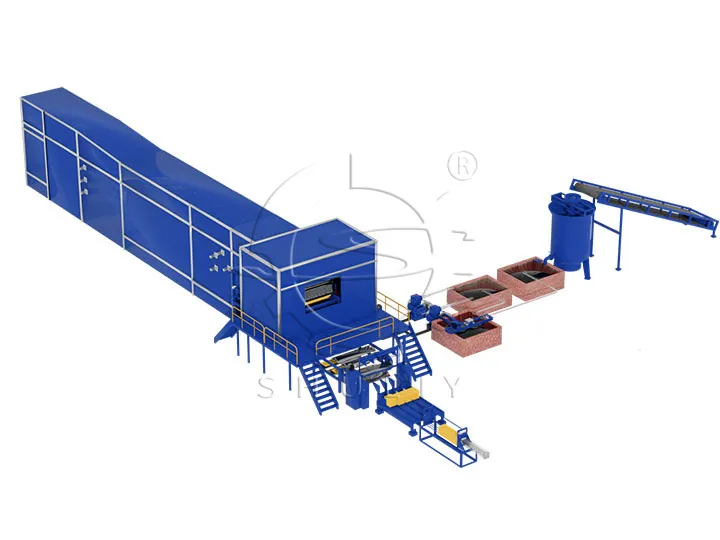

Compatible with Complete Production Line

This paper pulping machine can operate independently or be combined with equipment such as homogenizing tanks and storage tanks to form a complete pulping system. It can also be integrated with the egg tray forming machine, drying system, and other units to create a full egg tray manufacturing plant. According to customer needs, we offer various capacity options to suit different production scales.

Contact Us for Egg Tray Production Solutions

Whether you’re entering the pulp molding industry for the first time or planning to expand your existing production line, we can provide you with professional egg tray production solutions. From selecting the right paper pulping machine to designing the full production line layout, we tailor efficient and cost-effective equipment configurations based on your raw materials, capacity requirements, and factory conditions. Feel free to contact us anytime for detailed information and a customized quote.