El fabricante de pellets de plástico rígido desempeña un papel vital como equipo indispensable clave en la industria de procesamiento de plástico. En el Línea de reciclaje de escamas de PP PE, su función es cada vez más destacada, no sólo por la reutilización de residuos plásticos proporcionando una solución eficiente sino también por la protección del medio ambiente, el ahorro de recursos y otros aspectos que tienen importantes ventajas.

¿Qué es una peletizadora de plástico rígido?

Fabricante de pellets de plástico rígido. Es un tipo de equipo mecánico especializado en convertir residuos de plástico rígido en pellets de plástico. A través de una serie de procesos, tritura, funde y extruye productos de plástico rígido desechados, como recipientes de plástico, botellas, tuberías, etc., para eventualmente formar gránulos de plástico uniformes.

Estos pellets de plástico se pueden volver a utilizar como materia prima para la elaboración de productos plásticos, para facilitar su almacenamiento, transporte y reutilización. Este proceso no sólo ayuda a reducir las emisiones de residuos sino que también reduce el coste de las materias primas para los productos plásticos.

Flujo de trabajo De la máquina para fabricar pellets de plástico rígido peletizadora de hebras

- Pretratamiento: El fabricante de pellets de plástico rígido primero trata previamente el plástico rígido residual. A través del maquina trituradora de plastico rigido, los residuos plásticos de gran tamaño se trituran en pequeñas partículas adecuadas para su posterior procesamiento, lo que proporciona mejores condiciones de procesamiento para los pasos posteriores.

- Fusión y plastificación: Los gránulos de plástico triturados se introducen en la cámara de fusión de la máquina para fabricar pellets de plástico rígido peletizadora de hebras, donde se funden y plastifican por completo a alta temperatura y presión. Este paso ayuda a eliminar las impurezas del plástico residual y transforma el material plástico en un estado fundido con mejor fluidez.

- Extrusión y peletización: el plástico fundido se introduce en el mecanismo extrusor, donde se extruye y se moldea en gránulos de plástico de tamaño uniforme. Estos gránulos tienen una forma y un tamaño relativamente uniformes y son fáciles de almacenar, transportar y utilizar para su posterior procesamiento.

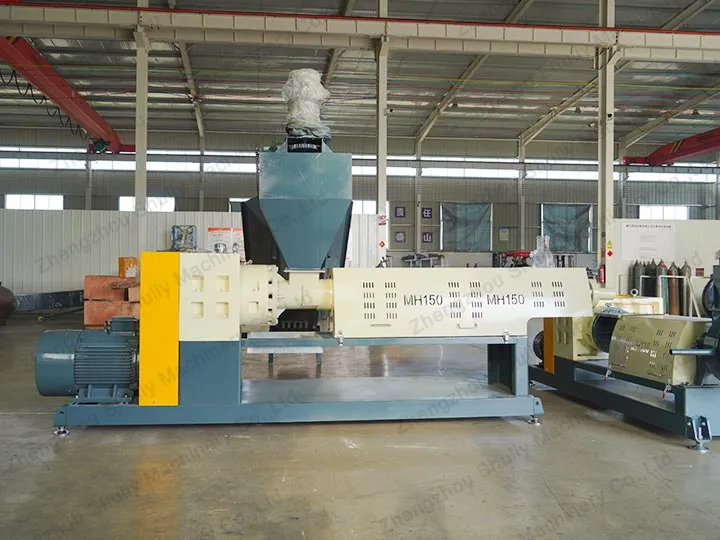

Máquina granuladora de plástico Shuliy a la venta

Como marca reconocida en el campo de los equipos de procesamiento de plástico, los fabricantes de pellets de plástico rígido Shuliy son muy respetados en la industria. Los peletizadores de plástico de la marca ofrecen los siguientes beneficios:

Capacidades de personalización flexibles

La máquina para fabricar pellets de plástico rígido Shuliy se puede personalizar según las necesidades y requisitos de los clientes. Ya sea el tipo de plástico, el tamaño de los pellets o el rendimiento, se puede adaptar a las necesidades específicas del cliente. Esta capacidad de personalización flexible garantiza la adaptabilidad y eficiencia de la línea de producción.

Si está interesado en el granulador de plástico Shuliy, puede dejar un mensaje en el sitio web o contactarnos directamente. Nuestro gerente comercial le presentará con entusiasmo los parámetros, el precio de la máquina granuladora de plástico y otros detalles.

Relación de consumo de energía de alta eficiencia

La máquina fabricadora de pellets de plástico rígido Shuliy adopta tecnología de fabricación avanzada con un alto índice de consumo de energía eficiente. Su exclusivo sistema de calefacción y refrigeración puede maximizar la utilización de energía, reducir los costos de producción y brindar considerables beneficios económicos a los usuarios.

Sistema de control automático

La moderna máquina de pellets de plástico rígido Shuliy está equipada con un sistema de control de automatización inteligente que puede monitorear la temperatura, la presión, el flujo y otros parámetros en el proceso de producción en tiempo real. Mediante un control preciso, se puede garantizar la estabilidad de la calidad de los gránulos de plástico y se puede reducir la variabilidad en la producción.

Salida de pellets de alta calidad

El fabricante de pellets de plástico rígido Shuliy adopta una tecnología de fusión avanzada para garantizar que el plástico esté completamente derretido y homogeneizado a altas temperaturas. Esto da como resultado la producción de gránulos de plástico de excelente calidad y alta estabilidad, que pueden usarse ampliamente en la producción de productos plásticos.