Seeking a high-performance, stable, and user-friendly egg tray making machine? We offer a range of egg tray forming machines and comprehensive egg tray production line solutions, featuring mold customization and flexible configurations to cater to diverse production requirements. Whether you’re investing in this field for the first time or planning to scale up your existing factory, we offer tailored equipment selection and technical support based on your budget, plant layout, and labor conditions.

Our egg tray machines have been successfully exported to numerous countries across Asia, Africa, the Middle East, and South America, earning wide recognition from our global clients.

What Is an Egg Tray Forming Machine?

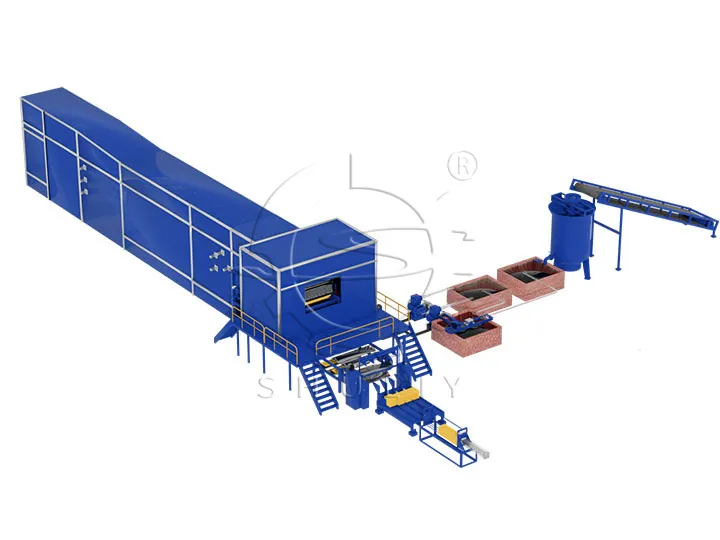

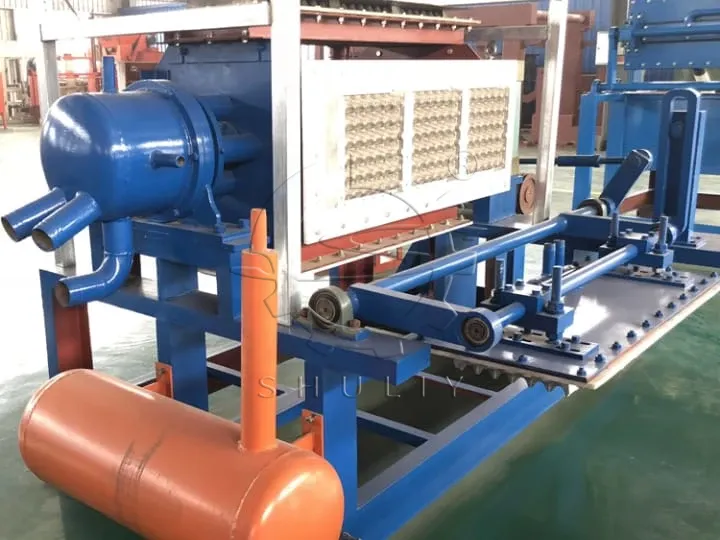

The egg tray making machine is the main equipment used to shape waste paper pulp into wet egg trays through vacuum suction and molds. It serves as the core component of the entire egg tray production line. When combined with the pulping system, drying system, and packing system, it enables continuous and automated production from raw materials to finished products.

We offer various models such as 3×1, 4×1, 3×4, and 4×4 to meet the needs of both small-scale workshops and large factories, with hourly output ranging from 1,000 to 8,000 egg trays.

Raw Materials and End Products

The egg tray machine uses various types of waste paper as raw materials, including:

- Carton scraps

- Old newspapers

- Office paper waste

- Books and magazines

Once pulped, these materials can be used to produce a wide range of paper tray products, such as:

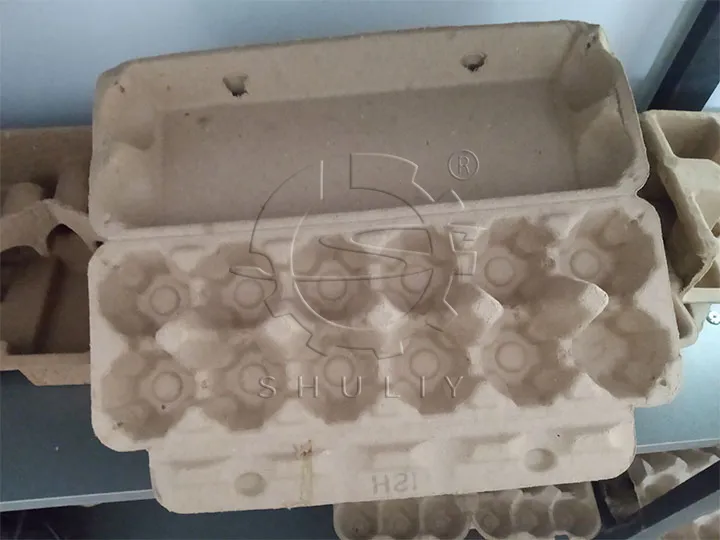

- 30-cell egg trays

- Egg cartons (6/10/12-count)

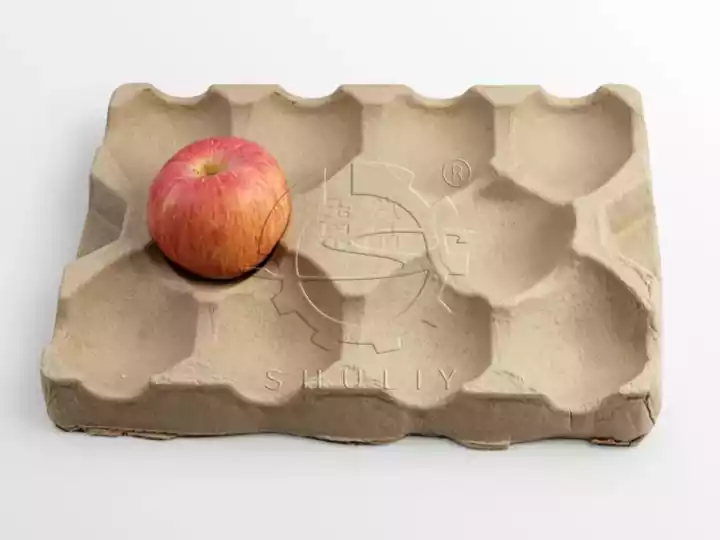

- Fruit trays

- Cup holders / coffee cup carriers

- Wine bottle trays, industrial packaging trays

- Shoe trays, electronic packaging inserts

Key Features and Advantages of Our Egg Tray Making Machine

- Custom mold support: Molds can be customized based on the product size and shape you require.

- High automation: Optional features like automatic pulp feeding, mold release, and stacking reduce labor costs.

- Full line integration: We offer complete solutions including pulping system, forming machine, drying system, and packing equipment.

- Multiple Models Available: Our egg tray machines offer capacities ranging from 1,000 to 8,000 pieces per hour, meeting the production needs of customers at all scales.

- Support for customization: personalised configurations according to different voltages, mould shapes, output requirements

Egg Tray Machine Models and Output Capacity

We offer a variety of egg tray making machine models to meet different production capacity requirements.

For small factories or startup projects, the 3×1 and 4×1 models are ideal, with an output of around 1,000 to 2,000 trays per hour.

Medium-sized factories often choose the 3×4 or 4×4 models, which produce approximately 2,000 to 3,000 trays per hour.

For large-scale production, the 4×8 model and above are recommended, capable of delivering 4,000 to 8,000 trays per hour, making them well-suited for fully automatic and highly efficient operations.

Each egg tray making machine model can be customized with specific molds and integrated with drying and packing systems to form a complete and efficient egg tray production line.

Why Choose Our Egg Tray Equipment?

- Customized Solutions: We provide professional equipment configuration recommendations based on your plant layout, raw materials, and budget.

- Rich Experience: With over 10 years of experience in manufacturing pulp molding equipment, we have served clients across Asia, Africa, South America, and other regions.

- Comprehensive Service: Our support covers equipment installation and commissioning, technical training, mold customization, and after-sales service.

How to Get the Egg Tray Making Machine Price?

The price of an egg tray manufacturing machine varies depending on several factors, including:

- Selected model and output capacity

- Quantity and type of molds required

- Whether a drying system is needed

- Voltage and plug standards of the destination country

- Shipping method (full container or LCL)

You can contact us through the following channels to receive an accurate quotation and project recommendation:

- Email: info@plasticsl.com

- WhatsApp / Phone: +86-17303821432

- You can also leave a message on our website — we will reply within 24 hours.

Whether you’re looking for a suitable egg tray making machine or planning to set up a complete and efficient egg tray manufacturing plant, we are here to offer professional support. Our engineering team will tailor the equipment configuration, plant layout, and quotation based on your specific requirements.