Over the years of working with egg tray production customers, we’ve often heard comments like: “The trays look uneven after drying,” or “The edges curl up and don’t stack well—what can we do?”

The answer is straightforward: introducing a hot pressing process, which is exactly what the egg tray hot pressing machine is designed for.

Role of the Hot Press Machine

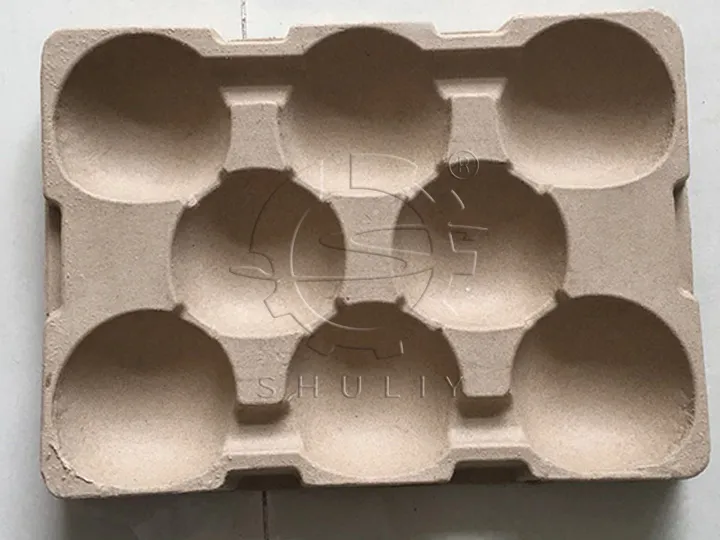

This egg tray hot pressing machine is used to reshape and flatten egg trays after they’ve been formed and dried. By applying heat and pressure through upper and lower molds, the tray edges become smoother, and the overall shape more consistent.

In our projects, we’ve found that:

- Hot-pressed trays are more resistant to deformation during transport

- They meet higher packaging standards, such as those required by supermarkets and e-commerce

- Uniform appearance increases product value and customer satisfaction

Key Features and Advantages

Customizable Molds: We can customize molds based on your egg tray size, making the machine compatible with various pulp molding products such as egg trays, fruit trays, or cup carriers.

Compact and Easy to Operate: The machine has a compact footprint and is easy to operate—standard training is enough for workers to get started quickly.

Improves Stackability:Hot-pressed trays are more uniform in shape, making them easier to stack and pack, which improves the efficiency of downstream processes like wrapping and strapping.

Application Scope and Compatible Products

This egg tray hot pressing machine is suitable for hot pressing and shaping a wide range of pulp molded products, such as:

- Chicken egg trays, duck egg trays, quail egg trays

- Fruit trays, disposable cup holders

- Food packaging trays, industrial cushioning trays, and more

Customers can customize molds based on product dimensions, or configure multiple mold sets to accommodate various tray types, improving equipment utilization.

Contact Us for a Tailored Egg Tray Production Line Solution

We understand that every customer has unique production needs and on-site conditions. Whether you’re setting up a new plant or looking to upgrade your existing line, we offer complete egg tray production solutions—including pulping, egg tray molding, drying, hot pressing, stacking, and packing. Feel free to contact us for a customized plan and detailed information.