Metal crusher is a heavy-duty metal crushing machine designed by us for scrap metal recycling and reprocessing applications. As a supplier with long-term experience serving metal recycling plants and scrap processing facilities, we have continuously optimized this machine based on real project feedback, so it can operate reliably as a standalone unit or be integrated into a complete metal crushing and sorting line to meet different production requirements.

Standalone Operation or Complete Metal Crushing and Sorting Line

When discussing solutions with customers, we usually recommend different configurations according to material type, processing capacity, and downstream separation requirements:

Standalone operation: suitable for small and medium-sized recycling stations or as a pre-crushing unit

Complete aluminum recycling plant configuration:

- metal shredders

- metal crusher machine

- eddy current separators

- metal dry grinding machines (polishing and impurity removal)

To form a complete metal crushing and sorting line, also commonly used in thermal break aluminum crushing and separation lines, enabling integrated crushing, separation, and upgrading of metal value.

Crushing More Than 200 Types of Metal Materials

In practical applications, this metal crusher is widely used in complex scrap metal scenarios and is capable of crushing more than 200 types of metal materials, including but not limited to:

- Flattened vehicle bodies and dismantled car body parts

- Light and thin metal materials that have been sheared or baled (density ≤ 1 t/m³)

- Household appliances such as old washing machines, refrigerators, air conditioners, and color steel sheets

- Scrap vehicle components, including motorcycles, electric bicycles, and bicycles

- Thin metal scrap, such as aluminum cans, paint buckets, and scrap aluminum

- Common scrap metals, including scrap steel, scrap iron, old metal parts, thermal break aluminum doors and windows, and radiators

Based on different materials, we can help customers select the appropriate model and configuration.

Stable Output Shape and Customizable Particle Size

Output size and material shape are key concerns for many customers:

- Standard output size: 3–10 mm

- Output material is granular or small ball-shaped

- Particle size can be customized according to customer requirements

Different materials produce different output forms:

- Thin materials such as aluminum cans → mainly ball-shaped output

- Thicker materials → flakes or small blocks

Conveying systems can be installed at both the inlet and outlet to ensure continuous and smooth material flow and easy integration with downstream separation equipment.

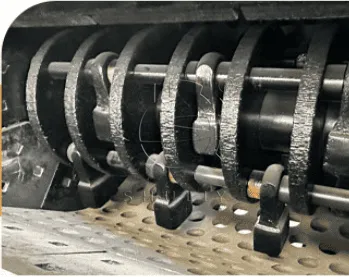

Hammer-Type Crushing with Long Wear Part Service Life

The scrap aluminum crusher adopts a hammer-type crushing structure, offering the following advantages in real-world use:

- Hammers and liners made of high-manganese wear-resistant steel

- Swing-type hammer installation with strong impact force

- When non-crushable objects enter the chamber, the hammers can swing away flexibly

- Non-crushable materials are discharged through a dedicated outlet, reducing machine damage

- The discharge size is controlled by the screen mesh, which can be customized.

This design improves operational safety while minimizing unplanned downtime.

Working Video of The Scrap Metal Crusher

Reinforced Machine Structure for Heavy-Duty Operation

During the design stage, special attention was given to long-term, high-load operation:

- Extra-thick steel plates combined with reinforced diagonal supports

- High overall structural strength to withstand overload crushing conditions

- Critical parts are reinforced with high-standard welding and structural strengthening

This structure has been proven in multiple continuous-operation projects and is especially suitable for metal recycling centers and large-scale scrap processing plants.

Main Technical Parameters of Metal Scrap Crusher

| Model | Power (kW) | Speed (r/min) | Production Capacity (kg/h) | Dimensions (mm) |

| SL-600 | 18.5–22 | 860 | 600–800 | 2000 × 1200 × 1900 |

| SL-800 | 30–37 | 860 | 800–1000 | 2200 × 1500 × 2200 |

| SL-1000 | 55–75 | 860 | 2500–3500 | 2800 × 1900 × 3100 |

| SL-1300 | 90–110 | 750 | 3500–5000 | 3500 × 2100 × 3800 |

| SL-1600 | 110 × 2 | 750 | 4000–8000 | 4400 × 2500 × 4200 |

| SL-1800 | 160 × 2 | 650 | 8000–12000 | 4700 × 2900 × 4500 |

| SL-2000 | 220 × 2 | 650 | 10000–18000 | 5000 × 3200 × 4600 |

Typical Application Fields

Based on our project experience, this metal scrap crusher is widely used in:

- Scrap metal recycling and reprocessing plants

- Scrap metal treatment centers

- Steel mills and affiliated recycling facilities

- Scrap metal collection and centralized processing enterprises

From Equipment Supply to Complete Solutions

As a long-term supplier of metal recycling equipment, we focus not only on machine specifications but also on real on-site performance. Whether you need a standalone metal crusher or plan to build a complete metal crushing and sorting line, we can recommend a suitable solution based on your materials, capacity targets, and site conditions.

Feel free to contact us with your project details. We are ready to support you with a practical and reliable metal crushing solution.