Plastiki povu pelletizing line ni hasa kutumika kwa ajili ya kuchakata na pelletizing mbalimbali taka povu. Plastiki ya taka hupondwa katika pellets ndogo za plastiki ambazo zinaweza kutumika mara mbili kama vifaa vya ufungaji, vifaa vya insulation, nk. Vifaa muhimu zaidi vya mstari wa povu wa plastiki ni extruder ya povu ya plastiki ambayo itayeyuka na kutoa pellets za plastiki.

Je! EPS Povu Na Nyenzo ya EPE?

EPS ya povu ni nyenzo ya kawaida ya plastiki ambayo hufanywa kutoka kwa polystyrene kupitia mchakato maalum wa usindikaji. Ni kawaida kutumika katika vifaa vya ufungaji, vifaa vya ujenzi, na bidhaa mbalimbali za nyumbani. Inapata jina lake kutokana na kuonekana kwake, ambayo kwa kawaida huchukua fomu ya povu nyeupe.

EPS ya povu hutumiwa sana katika vifaa vya ujenzi kwa sababu ya insulation yake bora ya mafuta na mali ya kunyonya mshtuko. Hata hivyo, mchakato wa utengenezaji wa povu ya EPS huzalisha gesi nyingi taka na maji machafu, ambayo husababisha uchafuzi wa mazingira. Maisha ya huduma ya EPS ya povu ni mafupi, ambayo haifai kwa ulinzi wa mazingira na maendeleo endelevu.

Polyethilini inayoweza kupanuka (EPE), inayojulikana kama pamba ya lulu. EPE ina mashimo mengi ya mapovu yanayotolewa na kemikali au kutokwa na povu. Povu ya pamba ya lulu ya EPE ni nyepesi na laini, ina athari ya kunyonya na kutawanya nishati chini ya hatua ya nguvu za nje kwa vitu vya mto. Inatumika sana katika fanicha za hali ya juu, bidhaa za elektroniki, dawa, na vitu vingine vya thamani na dhaifu vya ufungaji.

Malighafi na Bidhaa za Mwisho

Chanzo kikuu cha laini ya povu ya plastiki ni ufungashaji taka wa EPE EPS, kama vile masanduku ya chakula chenye povu, masanduku ya kufungashia yenye povu, vifuniko vya wavu wa matunda, povu la kifungashio la friji na taka nyingine nyeupe za povu.

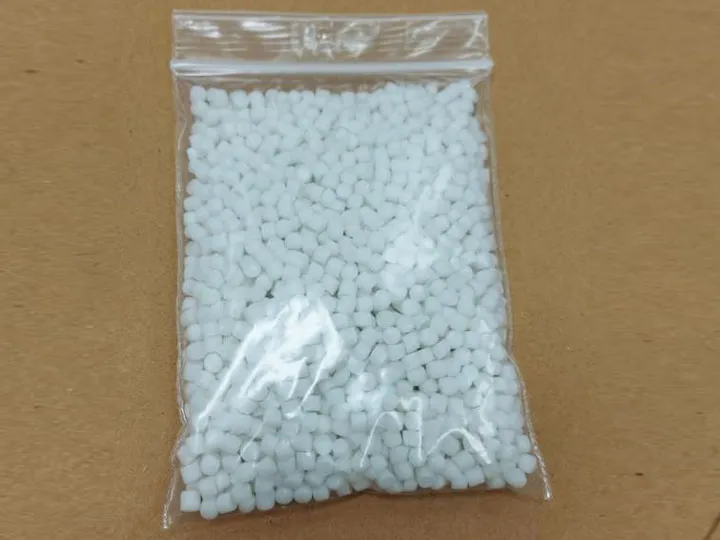

Kupitia laini ya povu ya plastiki, povu ya EPS na EPE hutiwa chembechembe na hatimaye, pellets mpya zilizosindikwa zinaweza kupatikana. Inaweza kufanywa kuwa bidhaa nyingine mpya za kutumika, na kutambua taka ili kuhifadhi povu.

Mchakato wa Kunyunyizia Povu wa EPE EPS

Kwa vile EPE na EPS zimeundwa kwa nyenzo tofauti, michakato yao ya granulation pia ni tofauti. EPE imetengenezwa kwa nyenzo laini na kichunaji cha EPE kinakuja na kifaa cha kulisha, kwa hivyo povu la EPE la taka linaweza kulishwa moja kwa moja kwenye mashine ya chembechembe ya povu ya EPE kwa usindikaji.

EPS, kwa upande mwingine, kwa sababu ya saizi yake kubwa, lazima kwanza ikatwe vipande vidogo na kipunyi cha povu, na kisha kwenye granulator ya EPS kwa granulation. Muundo wa mchakato huu unahakikisha kwamba kila nyenzo inaweza kubadilishwa kwa ufanisi kuwa pellets zilizosindikwa ili kukidhi mahitaji tofauti ya kuchakata tena.

Video ya Mstari wa Pelletizing wa Povu ya Plastiki

Vifaa Utangulizi wa Mashine ya Usafishaji wa Povu

Mashine ya kuyeyusha Povu ya EPS

Mashine ya kuyeyusha povu ya EPS imeundwa mahsusi kupunguza kiasi cha povu ya polystyrene iliyopanuliwa (EPS) kwa kusagwa, kuyeyuka kwa moto na ukingo wa extrusion. Inapunguza kiwango cha bidhaa za povu za EPS na nyenzo iliyoyeyuka inaweza kutumika kutengeneza bidhaa zingine za plastiki.

Kompakta ya Povu

Baada ya povu ya plastiki kusisitizwa na kompakt ya povu ya EPS, wiani wa povu huongezeka na hutengenezwa, ambayo ni rahisi sana kwa usafiri na kuhifadhi. Kuna aina mbili za viunganishi: viunganishi vya povu vya EPS vya wima na viunganishi vya usawa vya povu vya EPS.

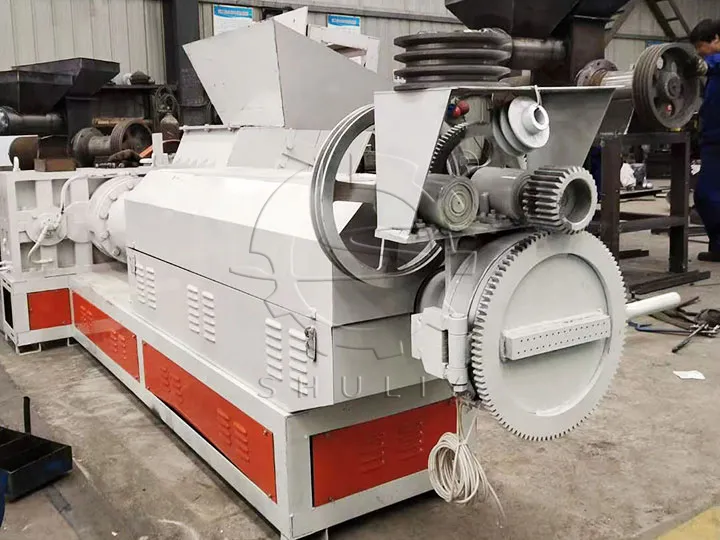

Plastiki Povu Granulator

Granulator ya povu ya plastiki ni mojawapo ya mashine muhimu zaidi katika mstari wa pelletizing ya povu ya plastiki. Granulator inaweza kuyeyusha na kutoa plastiki taka za EPE na EPS kwenye chembechembe za plastiki zinazoweza kutumika tena.

Tangi ya Kupoeza

Tangi la kupozea hutumika kupoza na kuimarisha vipande virefu vya plastiki vilivyotolewa vya povu ya kutolea nje ya plastiki ili kuwezesha hatua inayofuata ya kuvikata katika vigae vya ukubwa sawa.

Mashine ya Kukata Pellet ya Plastiki

Mashine ya kukata pellet ya plastiki inaweza kukata vipande vya muda mrefu vya plastiki kwenye vidonge, na ukubwa wa pellets unaweza kubadilishwa. Bodi kuu imewekwa na sahani ya chuma cha pua ili kuzuia kwa ufanisi uchafuzi wa pellet ya plastiki.

Vipengele za Mstari wa Kusambaza Povu ya Plastiki

- Laini ya povu ya plastiki ina mchakato rahisi, teknolojia ya juu, matumizi ya chini ya nguvu, hakuna uchafuzi wa mazingira, na kiwango cha juu cha automatisering.

- Pato la juu na gharama ya chini ya umeme. Utendaji wa juu na gharama ya chini ya matengenezo.

- Kiwango cha juu cha automatisering na akili katika uendeshaji wa nzima EPE EPS povu granulating line. Rahisi kufanya kazi, nafasi ndogo, na waendeshaji kutumia.

- Msongamano mkubwa wa pellets baada ya plastiki na extrusion, hakuna mashimo ya hewa, uso mzuri, pato la juu, na extrusion imara.

Mashine ya Urejelezaji wa Styrofoam Inauzwa

Tunatoa anuwai ya mashine za kuchakata povu ili kukidhi mahitaji ya wateja tofauti. Mashine zetu sio tu kwamba zinakandamiza povu kwenye vizuizi kwa urahisi wa kuhifadhi na usafirishaji, lakini pia kuyeyusha povu kwenye vizuizi kupitia teknolojia ya kuyeyuka kwa moto ili kupunguza zaidi sauti.

Kwa kuongezea, vichungi vyetu vya povu vinaweza kuchakata povu la taka ndani ya vidonge vya ubora wa juu kwa matumizi anuwai ya utengenezaji. Kwa aina yoyote ya kuchakata povu unayohitaji, tunaweza kukupa vifaa vya kuaminika na masuluhisho ya kina. Ikiwa una nia ya mashine yetu ya kuchakata povu, tafadhali jisikie huru kuwasiliana nasi.