Maskin yetu ya pelletizing ya filamu za plastiki ni vifaa maalum kwa ajili ya kurejeleza na kusindika filamu za plastiki zilizotumika. Kazi yake kuu ni kubadilisha filamu za plastiki zilizorejelewa kupitia hatua kadhaa za usindikaji kuwa granules za plastiki zilizo sawa, ambazo zinaweza kutumika kama malighafi za kurejeleza kwa uzalishaji wa bidhaa mpya.

Uwezo wa uzalishaji wa mashine ni 180-420 KG/H, ambayo inaweza kubadilishwa kulingana na mahitaji maalum ya wateja ili kuhakikisha inakidhi mahitaji ya uzalishaji wa biashara za urejeleaji za aina mbalimbali. Mashine yetu ya urejeleaji ya pelletizing inatoa suluhisho la gharama nafuu kwa wateja wetu kwa sababu ya ufanisi wake wa juu, uhifadhi wa nishati, na sifa rafiki kwa mazingira.

Tafadhali angalia video kabla hatujakuambia zaidi kuhusu granulator yetu ya kuchakata plastiki.

Malighafi za mashine ya kuchakata filamu za plastiki.

Efter att ha introducerat rollen och kapaciteten hos plastfilmgranulatorn kanske du undrar vilken typ av råmaterial som är lämpligt för denna maskin. Vår plastfilmspelleteringsmaskin används i stor utsträckning för bearbetning av alla typer av plastfilmavfall som polyeten (PE), polypropen (PP), polyvinylklorid (PVC) och så vidare.

Oavsett om det handlar om plastpåsar, vävda påsar, jordbruksfilm, förpackningsfilm eller industriell film, kan denna maskin effektivt bearbeta det och omvandla det till högkvalitativa återvunna pellets. Om ditt företag är involverat i återvinning och återanvändning av dessa avfall plastfilmer, kommer denna maskin att vara idealisk för dig.

Fördelar med plastfilm pelletiseringsmaskin

Hög effektivitet och energibesparing

Genom att anta avancerad uppvärmningsteknik och ett effektivt pelletiseringssystem kan det snabbt omvandla plastfilm till pellets och förbättra produktionseffektiviteten.

Noggrann temperatur- och processkontroll

Mashine ya kuunda vidonge vya filamu za plastiki imetengenezwa na mfumo wa kudhibiti joto wa kisasa na teknolojia ya kudhibiti mchakato ili kuhakikisha kuwa filamu za plastiki zinaundwa vidonge kwa joto bora la usindikaji. Hii inahakikisha ubora thabiti wa vidonge, inapunguza kiwango cha taka, na inaboresha ushindani wa soko wa bidhaa.

Mångsidig och anpassningsbar

Inayoweza kushughulikia aina mbalimbali za filamu za plastiki na unene kwa kiwango cha juu cha kubadilika na uwezo wa kujiandaa. Kukidhi mahitaji tofauti ya uzalishaji ya wateja, na inaweza kubinafsishwa kulingana na mahitaji maalum.

Stabil drift och låga underhållskostnader

Vifaa vina muundo thabiti, ni rahisi kutumia, na vina gharama za chini za matengenezo, hivyo kupunguza gharama za uendeshaji za mteja.

Kanuni ya kufanya kazi ya mashine ya kuchakata pellets za plastiki.

Sasa, hebu tutambulisha kanuni ya kufanya kazi ya mashine ya kuchakata filamu za plastiki.

Materialet krossas och rengörs vanligtvis innan det går in i pelletiseringsåtervinningsmaskinen, vilket säkerställer kvaliteten på pellets.

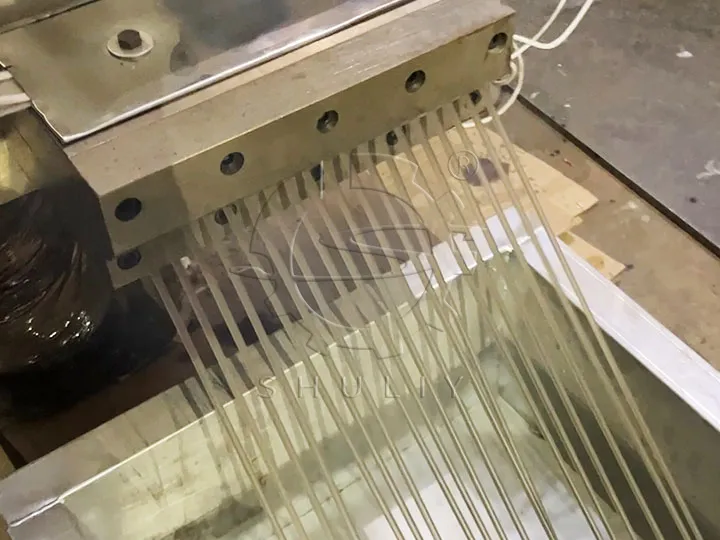

Vipande vya filamu za plastiki vilivyoshindikwa na kusafishwa vinaingia kwenye extruder ya pellet za plastiki kwa ajili ya kuyeyushwa. Plastiki iliyoyeyuka inasukumwa kwenye kichwa cha die cha extruder kupitia mzunguko wa screw, na kichwa cha die kinatoa strip ya plastiki isiyo na mwisho.

Hizi strip za plastiki hupozwa na kutibiwa na kifaa cha kupoza na hatimaye hukatwa kuwa vipande vya plastiki vya kawaida na mashine ya kukata pellets. Pellets hizi zinaweza kutumika moja kwa moja katika uzalishaji wa bidhaa mpya au kuuzwa kwa watengenezaji wengine kama nyenzo zilizorejelewa.

Struktur av plastpelletmaskin

Sasa tunakuletea muundo wa mashine ya pellet ya plastiki ili kukusaidia kuelewa kanuni ya kazi ya mashine hiyo. Muundo wa mashine unajumuisha sehemu kuu zifuatazo:

- Mfumo wa kulisha: Inatumika kulisha plastiki zilizovunjwa kwa usawa kwenye mashine ya kutengeneza pellet za filamu za plastiki. Kushughulikia vifaa vya filamu kwa kawaida kunaweza kuunganishwa na kifaa cha kulisha kiotomatiki.

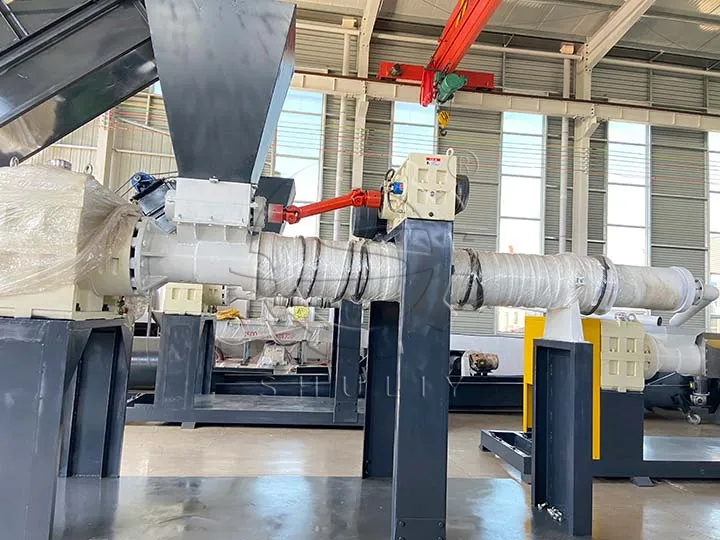

- Mfumo wa kutolea: Ni sehemu kuu ya mashine ya kutengeneza plastiki, hasa inaundwa na silinda ya kutolea na screw. Screw inageuka ndani ya silinda ili kupasha joto, kuyeyusha na kusukuma plastiki hadi kwenye kichwa cha die.

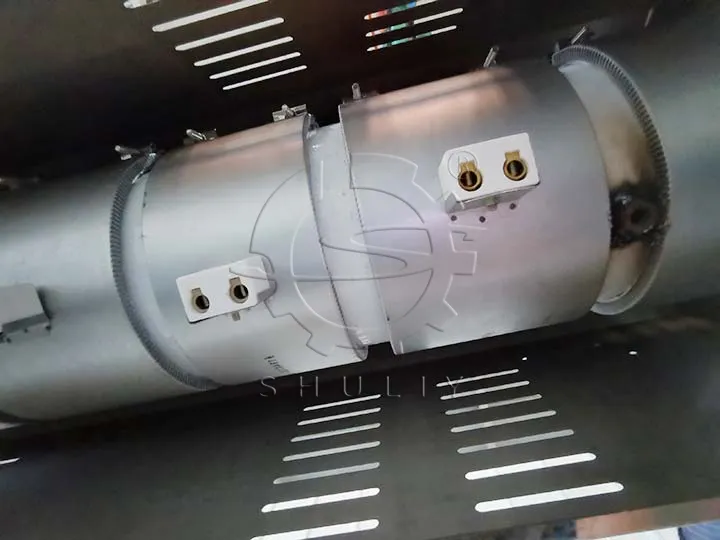

- Uppvärmningssystem: Inkluderar en värmeenhet och en elektrisk kontrollbox för att styra temperaturen inuti extrudern.

- Die Head: Installerad vid utloppsänden av plastfilmspelletiseringsmaskinen, extruderas och formas plastsmältan genom die head. Designen av die head bestämmer formen och storleken på den extruderade plastremsan.

Hjälputrustning för plastfilmgranulator

När man bearbetar plastfilm material krävs en automatisk matningsanordning på plastpelletsextrudern. Anledningen till detta är att plastfilm material är lätt och tenderar att driva och ackumuleras. Den automatiska matningsanordningen kan kontinuerligt och jämnt mata film materialet in i granulatorn, förbättra matningseffektiviteten och säkerställa kontinuitet och stabilitet i produktionen.

Tekniska parametrar för plaståtervinningsgranulator

Shuliy ina anuwai kubwa ya mashine za recykling za filamu za plastiki kusaidia wateja kuboresha ufanisi wao wa recykling wa plastiki, ambapo mifano inaitwa kwa ukubwa wa kipenyo cha screw. Hapa chini kuna baadhi ya mashine zetu maarufu za kutengeneza pellets za filamu za plastiki, ikiwa unahitaji kujua mifano mingine ya mashine za kutengeneza pellets za plastiki, tafadhali jisikie huru kutupelekea ujumbe.

SL-125

Kipenyo cha screw: 125mm

Kasi ya spindle: 50-70/min

Huvudmotor effekt: 30kw

Reducer hård växel: 225

Vikt: 1.8T

Storlek: 2.6*0.7*0.7m

Uppgift: 180KG/H

SL-180

Diameter ya screw: 180mm

Kasi ya spindle: 40-50/min

Nguvu ya motor kuu: 55kw

Gear ngumu ya reducer: 280

Uzito: 2.2T

Kipimo: 3.2*0.7*0.8m

Matokeo: 350KG/H

SL-220

Skruvdiameter: 220mm

Kasi ya spindle: 40-50/min

Nguvu ya motor kuu: 90kw

Reducer ngumu gear: 330

Uzito: 3.2T

Kipimo: 3.8*1.2*1m

Matokeo: 420KG/H

Uppvärmningsmetoder för plastgranulatmaskin

Pelletizers za plastiki kwa kawaida hutumia njia mbalimbali za kupasha joto ili kupasha joto silinda ili kuyeyusha na kuunda pellet za nyenzo za plastiki. Hapa chini kuna njia tatu za kawaida za kupasha joto ambazo unaweza kuchagua kulingana na mahitaji yako ya uzalishaji.

Ujoto wa Electromagnetic

- Principle: Genom principen för elektromagnetisk induktionsuppvärmning används den elektromagnetiska induktionsringen för att generera ett elektromagnetiskt fält runt tunnan, vilket värmer upp den plastiska råvaran.

- Fördelar: enhetlig uppvärmning, hög effektivitet, energibesparing och snabb svarstid.

- Lämplighet: Särskilt lämplig för applikationer som kräver snabb uppvärmning och precis temperaturkontroll.

Ujoto wa Keramiki

- Kipengele: Kutumia hita za keramik kugeuza nishati ya umeme kuwa nishati ya joto, silinda inakabiliwa na umeme wa ndani ya mwili wa upinzani wa keramik ili kuzalisha joto.

- Fördelar: stabil och pålitlig, påverkas inte lätt av förändringar i omgivningstemperaturen, med god högtemperaturmotstånd.

- Lämplighet: Lämplig för långvarig stabil uppvärmning, inte särskilt krävande temperaturkrav för applikationen.

Vanlig elektrisk uppvärmning

- Kanuni: Kupitia waya wa upinzani au bomba la joto la umeme lililopashwa moja kwa moja, matumizi ya nishati ya umeme kubadilishwa kuwa nishati ya joto ili kupasha joto malighafi za plastiki.

- Fördelar: enkel drift, låga utrustningskostnader, lätt underhåll.

- Taaluma: Inatumika sana katika granulator ndogo za plastiki au vifaa vinavyohitaji udhibiti rahisi wa joto, udhibiti wa joto unaweza kuwa mbaya kidogo ikilinganishwa na mbinu nyingine.

Mifano ya mafanikio ya mashine za kuchakata filamu za plastiki.

Granulator ya filamu za plastiki ikifanya kazi nchini Saudi Arabia.

Wakati mteja huyu wa Saudi Arabia alipotushauri, alikuwa tayari amekusanya kiasi kikubwa cha nyenzo za filamu na alikuwa anapanga kufungua kiwanda cha kuchakata na kusindika plastiki. Alihitaji kusindika filamu ya plastiki kuwa pellets za plastiki, na baada ya mawasiliano ya kina,alichagua mashine yetu ya kutengeneza pellets za filamu ya plastiki. Kwa msaada wa wahandisi wetu, ilizinduliwa kwa mafanikio.

Mashine ya kuchakata pellets za plastiki imetumwa Botswana.

Tulijifunza kuhusu mahitaji ya mashine za kuchakata plastiki kutoka kwa uchunguzi wa mteja huyu wa Botswana. Baada ya mawasiliano ya kina na kuelewa mahitaji maalum ya mteja, tulitoa suluhisho maalum na kuthibitisha nukuu husika. Baada ya mteja kuthibitisha agizo, tulipanga kwa haraka uzalishaji na uanzishaji ili kuhakikisha kuwa vifaa vilitumwa kwa wakati na kufika kwenye eneo la marudio kwa urahisi.

Rekommenderad plastfilm återvinningslinje

Ili kutimiza vyema urejelezaji na matumizi tena ya filamu ya plastiki, inapendekezwa kuunganishalaini ya kuchakata filamu ya plastiki. Kiwanda hiki cha kutengeneza pellets za plastiki kinajumuisha vipasua plastiki, mashine za kutengeneza pellets za plastiki, mashine za kukata pellets za plastiki, na vifaa vingine vya kuchakata plastiki kwa ajili ya pellets za plastiki zilizorejeshwa, na kuunda mchakato kamili wa uzalishaji ambao unatambua ubadilishaji mzuri kutoka kwa filamu ya plastiki taka hadi pellets za plastiki zilizorejeshwa.

Wasiliana nasi kwa bei ya mashine ya granulator ya plastiki!

Je, una nia ya kuchakata filamu ya plastiki? Ikiwa ndivyo, tunafurahi kukusaidia! Tunataalam katika suluhisho za kibinafsi kwa wateja wetu na tunahakikisha kukupa nukuu bora kwa mashine za kuchakata filamu ya plastiki kulingana na mahitaji na bajeti yako. Tafadhali jisikie huru kuwasiliana nasi na tushauriane jinsi bora ya kushughulikia mahitaji yako ya kuchakata filamu ya plastiki!