Na sociedade atual, o uso extensivo de produtos plásticos resultou em uma grande quantidade de resíduos plásticos. Para lidar com esses resíduos de forma eficaz, surgiram vários tipos de máquinas trituradoras de plástico. Neste artigo, focaremos em dois tipos comuns de trituradores de plástico: triturador de filme plástico e triturador de garrafa PET. Essas duas máquinas desempenham um papel integral no descarte de resíduos, mas diferem significativamente em design e função.

Triturador de filme plástico

O triturador de filme plástico é uma máquina projetada para processar resíduos de filme plástico. Ele possui algumas características únicas que o tornam excelente no processamento de plásticos de filme. Aqui estão as principais características do triturador de filme plástico.

Tamanho da tela

Os trituradores de filme plástico têm tamanhos de tela maiores em comparação com os trituradores de garrafas PET. Normalmente, o tamanho da tela usada para filmes plásticos é de cerca de 90 mm. Esse tamanho de tela relativamente grande ajuda a processar o filme plástico de forma eficiente, prevenindo entupimentos e desgaste excessivo.

Materiais aplicáveis

Os trituradores de filme plástico são usados principalmente para processar filmes plásticos, como sacolas plásticas, filmes de embalagem e filmes agrícolas. Esses materiais geralmente têm baixa densidade e características macias, e requerem um triturador especialmente projetado para processá-los de forma eficaz.

Método de corte

A máquina de esmagamento de plástico descartado geralmente adota o método de cisalhamento para cortar. Esse método de corte pode efetivamente cortar plástico filme em pequenos pedaços sem causar excesso de poeira e calor.

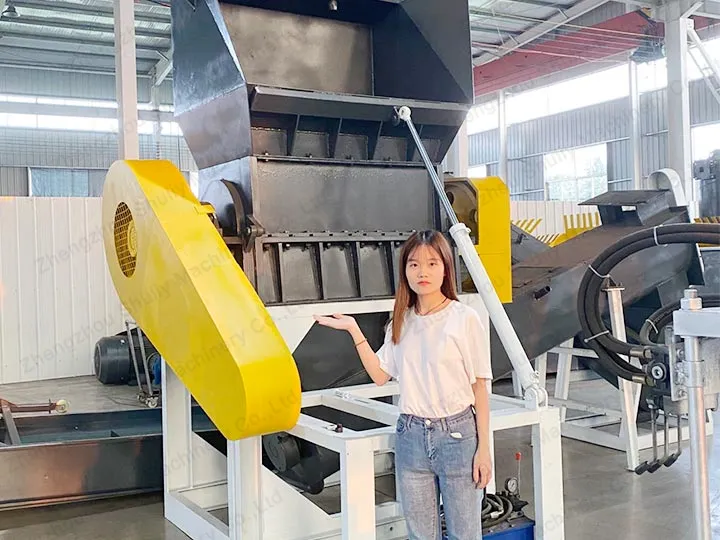

triturador de garrafas PET

Triturador de garrafas PET, também conhecido como triturador universal de garrafas plásticas, é um equipamento multifuncional adequado para processar todos os tipos de resíduos plásticos duros. A seguir estão as principais características do triturador de garrafas plásticas.

Tamanho da tela

Comparado com o triturador de filme plástico, o tamanho da tela do triturador de garrafas PET é menor, geralmente 24mm. Esse tamanho de tela menor permite que ele triture resíduos plásticos duros em pedaços menores.

Materiais aplicáveis

O triturador de material duro é adequado para processar resíduos plásticos duros, como recipientes plásticos, tubos, produtos moldados por injeção e assim por diante. Esses materiais geralmente são mais duros e requerem uma força de trituração mais poderosa para serem manuseados.

Método de corte

O triturador de garrafas PET geralmente adota o método de corte por lâmina. Esse tipo de corte pode quebrar efetivamente plásticos duros em pequenas partículas e usá-las para reciclagem ou outra disposição.

Importância da máquina de trituração de plástico residual

Seja um triturador de filme plástico ou um triturador de garrafa plástica, eles desempenham um papel fundamental no processamento e reciclagem de plásticos descartados. A capacidade das máquinas de trituração de plásticos descartados de desintegrar os plásticos em uma forma que pode ser facilmente processada ajuda a reduzir o volume de resíduos, aumentar a eficiência da reciclagem e diminuir a dependência de recursos naturais.