Boas notícias! A linha de lavagem de filme plástico da Shuliy foi enviada com sucesso para a Costa do Marfim. Durante esta cooperação, os clientes da Costa do Marfim ficaram muito satisfeitos e apreciaram muito os produtos e serviços da Shuliy Machinery. Se você quiser saber mais sobre os produtos e serviços da Shuliy, por favor, leia mais informações detalhadas sobre esta transação!

Necessidades do cliente

A Costa do Marfim, um país localizado na África Ocidental, possui um rico recurso de filme plástico residual. Nosso cliente, um reciclador de plástico experiente, havia comprado anteriormente equipamentos de peletização em outro lugar.

No entanto, havia uma série de problemas com seu equipamento existente que afetavam a produção e a qualidade. Portanto, ele estava procurando um parceiro confiável para fornecer um conjunto de linha de lavagem de filmes plásticos eficientes para expandir a capacidade de produção, evitando os problemas anteriores.

Por que o cliente escolheu a linha de lavagem de filme plástico Shuliy?

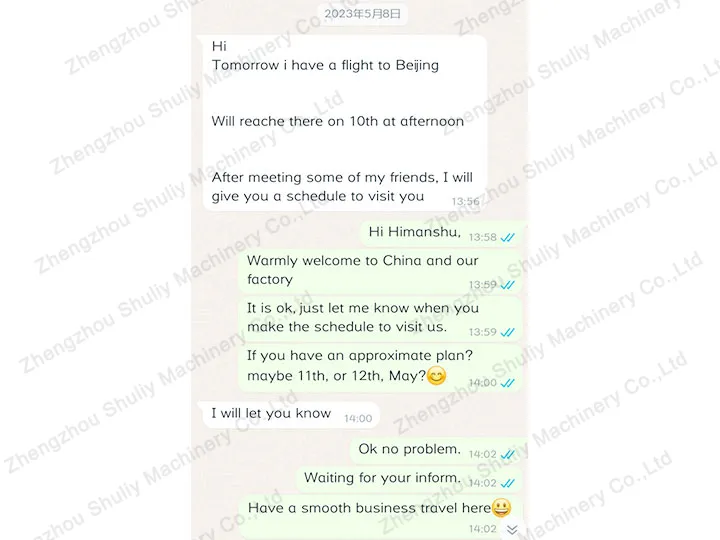

- Solução profissional: No processo de busca por uma solução, o cliente entrou em contato com nossa gerente de projeto, Helen, que não apenas ouviu as perguntas do cliente, mas também respondeu às suas preocupações de maneira oportuna. Além disso, Helen compartilhou ativamente o vídeo da fábrica e informações detalhadas sobre o produto para mostrar ao cliente o desempenho superior da linha de lavagem de filme plástico Shuliy.

- Máquina superior: Nossas respostas profissionais e comunicação atenta conquistaram a confiança do cliente. O cliente decidiu visitar a fábrica da Shuliy para ter uma compreensão mais abrangente do desempenho e da qualidade do produto. Após a visita ao local, o cliente demonstrou alta satisfação com a linha de lavagem de filme plástico da Shuliy.

Parâmetros da linha de granulação de reciclagem de plástico

Os seguintes são os parâmetros desta linha de lavagem de filme plástico, toda a linha de peletização pode ser personalizada de acordo com as necessidades dos clientes. Se você tiver alguma dúvida, sinta-se à vontade para nos consultar.

| Máquina | Especificação |

| Transportador de correia | Comprimento: 5m Largura: 1m Potência: 2.2kw Com rolo magnético |

| Triturador de plástico | Modelo: SLSP-600 Potência do motor: 30 kw Capacidade: 600-800kg/h 10 facas Material das lâminas: 60Si2Mn |

| Máquina de limpeza de tanque duplo poderosa e tubo de aquecimento | Potência do motor: 7.5kw Dimensões: 5.0m*1.4m*1.6m Diâmetro: 0.6m*2Lâmina Espessura: 10mm Espessura da parede externa: 4mm Material: Q235 Potência de aquecimento: 60kw |

| máquina de desidratação por elevação | Potência do motor: 7.5kw Dimensões: 2,6m*0,7m Diâmetro: 0,5m Peso: 450kg Espessura da lâmina: 6mm Espessura da parede externa: 4mm Material: Q235 |

| Tanque de lavagem | Potência do motor: 4kw Dimensões: 4.5*1.2*1.3 Potência do motor redutor: 1.5kw Peso: 1200kg Espessura da lâmina: 6mm Espessura da parede externa: 3mm Material: Q235 |

| Secador horizontal | Secura: 98% Potência do motor: 15kw Dimensões: 2,5m*1,0m Tela: feita de aço inoxidável 304 Espessura da lâmina: 10mm Espessura do eixo: 8mm |

| máquina de peletização de plástico | máquina de fazer pellets Host Modelo: SL-150 Potência: 37kw 2.3parafuso Método de aquecimento: aquecimento cerâmico Redutor de engrenagem endurecido segunda máquina de fazer pellets Modelo: SL-125 Potência: 11kw Parafuso de 1,3m Método de aquecimento: aquecimento por anel Redutor de engrenagem endurecido Material do parafuso: 40Cr (Alta dureza e resistência ao desgaste) Material da manga: aço No.45 tratado termicamente Matriz Hidráulica Dupla Potência: 3KW (Mudar máquina sem parar) |

| Resfriamento tanque | Comprimento: 3m Material: aço inoxidável |

| Máquina de corte de pellets | Regulação de velocidade do conversor Potência: 3kw Lâminas de hob |

| Caixa de armazenamento | Potência: 2.2kw Um soprador de alta pressão entrega os pellets e remove a água dos pellets. |

Linha de granulação de reciclagem de plástico enviada para a Costa do Marfim