Mesin penghancur botol PET adalah salah satu mesin terpenting dalam lini daur ulang botol PET, terutama digunakan untuk menghancurkan botol plastik menjadi serpihan PET, dan kapasitas produksinya berkisar antara 500-3000kg/jam. Shuliy terkenal di kalangan produsen penghancur sisa botol PET karena mesinnya yang berperforma tinggi. Penghancur botol PET ini memiliki kapasitas penghancuran yang kuat dan lebih disukai karena biayanya yang rendah, daya tahan, dan ramah lingkungan.

Kami menawarkan berbagai macam penghancur botol PET untuk Anda pilih dalam hal model, kapasitas, dan tampilan untuk memenuhi kebutuhan pelanggan yang berbeda. Selain itu, kami juga dapat menyesuaikan mesin dengan kebutuhan spesifik Anda untuk memastikan mesin tersebut cocok dengan proses produksi dan tata ruang Anda. Layanan penyesuaian yang fleksibel ini memungkinkan mesin penghancur botol plastik kami memaksimalkan kebutuhan spesifik Anda, serta meningkatkan efisiensi dan produktivitas.

Pengenalan Mesin Penghancur Botol PET

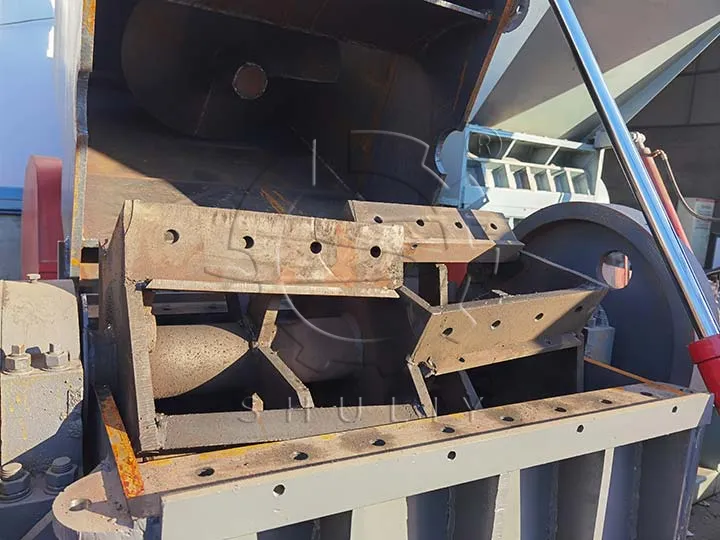

Mesin penghancur botol plastik merupakan mesin efisien yang dirancang untuk mengolah limbah botol PET. Mesin ini mengadopsi teknologi pemotongan dan pisau material 9CrSi yang canggih, yang dapat dengan cepat dan efisien menghancurkan botol PET menjadi potongan-potongan kecil yang seragam untuk pembersihan dan daur ulang selanjutnya.

Mesin penghancur botol PET kami memiliki struktur kokoh dan mudah dioperasikan, cocok untuk operasi daur ulang segala ukuran. Kapasitas penghancurannya yang sangat efisien dan konsumsi energi yang rendah tidak hanya meningkatkan produktivitas namun juga mengurangi biaya pengoperasian, menjadikannya pilihan ideal bagi perusahaan daur ulang.

mesin penghancur botol plastik

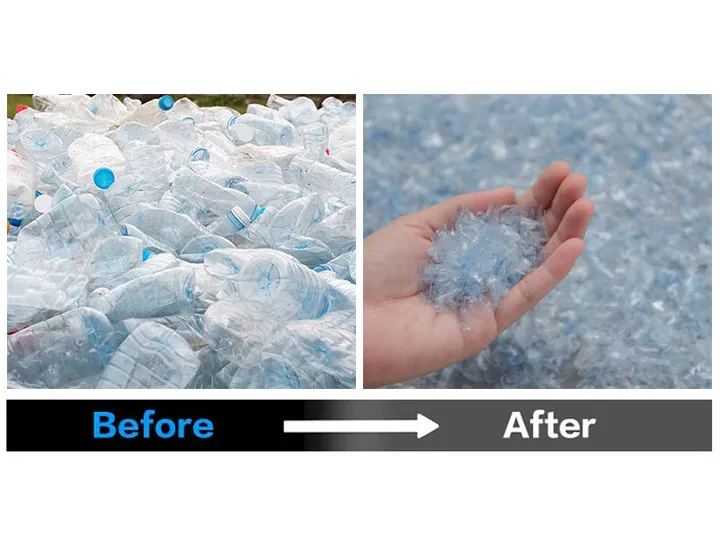

Bahan Baku & Produk Jadi Penghancur Botol Plastik

Penghancur botol PET terutama digunakan untuk memproses semua jenis limbah botol dan wadah PET. Bahan baku tersebut antara lain botol minuman, botol kemasan makanan, botol kosmetik, dan berbagai jenis produk plastik PET lainnya. Melalui pemrosesan mesin penghancur yang efisien, bahan mentah ini dihancurkan menjadi partikel atau pecahan kecil untuk didaur ulang dan diproses selanjutnya.

Serpihan ini juga dapat dibersihkan dan dikeringkan lebih lanjut untuk menghasilkan serpihan botol PET daur ulang yang bernilai lebih tinggi. Selesai PELIHARAAN serpihan dapat digunakan untuk berbagai aplikasi daur ulang, seperti pembuatan pelet PET daur ulang untuk produksi produk plastik baru, atau digunakan langsung di industri tekstil untuk membuat serat poliester.

Fitur Penghancur Botol Plastik

- Mesin penghancur botol air ini banyak digunakan, dapat menghancurkan botol PET dan PVC, juga dapat menghancurkan plastik PP PE.

- Alat mesin penghancur botol plastik ini terbuat dari bahan 9CrSi, bilah bahan baja paduan khusus setelah perlakuan pengerasan, kecepatan potong cepat, bilah tahan lama, dan dapat digiling untuk penggunaan berulang.

- Mesin penghancur botol PET mudah dioperasikan, menghemat tenaga kerja, dan memiliki output lebih tinggi dengan konsumsi daya rendah. Ini secara efektif mengurangi biaya produksi pelanggan.

- Pisau putar pada mesin penghancur PET dirancang dengan aksi pemotongan gunting dan sudut pemotongan yang efektif untuk memastikan penggilingan yang efektif.

- Struktur dan tampilan warna penghancur botol plastik Shuliy dapat bervariasi karena pembaruan versi dan perbedaan model. Kami menyediakan layanan khusus untuk penghancur plastik, selamat datang untuk menghubungi kami untuk solusi khusus yang sesuai dengan kebutuhan Anda.

Prinsip Kerja Mesin Penghancur Botol PET

Prinsip kerja penghancur botol PET adalah menghasilkan gaya geser dan gaya tumbukan yang kuat dengan putaran bilah yang digerakkan motor, yang menghancurkan botol PET dan bahan plastik lainnya menjadi partikel kecil. Setelah bahan mentah masuk ke dalam penghancur, bahan tersebut dicukur dan disobek oleh bilah yang berputar cepat hingga mencapai ukuran partikel yang dibutuhkan.

Seluruh proses mengontrol ukuran partikel melalui layar untuk memastikan keseragaman produk jadi. Ukuran layar mesin penghancur botol PET adalah 16-18mm, yang dapat disesuaikan dengan kebutuhan spesifik pelanggan. Keripik PET yang dihancurkan dapat langsung dibersihkan dan diproses ulang, sehingga menghasilkan bahan mentah berkualitas tinggi untuk daur ulang selanjutnya.

Video Aplikasi Penghancur Botol Plastik

Mesin penghancur botol PET memainkan peran penting dalam jalur daur ulang pencucian botol PET. Ini dapat secara efisien menghancurkan botol limbah PET menjadi partikel kecil untuk pembersihan selanjutnya dan pengolahan ulang.

Melalui penghancuran, volume botol PET berkurang secara signifikan, sehingga meningkatkan efisiensi pembersihan dan efek pembersihan. Pelet PET yang dihancurkan dapat lebih mudah menghilangkan minyak, lendir, dan residu label dari permukaan, sehingga menjadi landasan yang kokoh untuk produksi serpihan botol PET daur ulang berkualitas tinggi.

Video di bawah ini menunjukkan peran penting mesin penghancur botol PET dan proses daur ulang botol PET secara lengkap untuk Anda tonton.

Parameter Penghancur Botol Plastik

Mesin penghancur botol PET Shuliy tersedia dalam berbagai model untuk memenuhi kebutuhan pemrosesan yang berbeda. Mesin penghancur botol plastik ini memiliki kapasitas pemrosesan yang sangat efisien dan cocok untuk menghancurkan dan menggunakan kembali berbagai macam botol PET seperti berbagai botol air mineral, botol minuman berkarbonasi, dan masih banyak lagi.

| Model | SL-60 | SL-80 | SL-100 | SL-120 |

| Kapasitas (kg/jam) | 500 | 1000 | 1500 | 3000 |

| Motor (kW) | 22 | 37 | 75 | 90 |

| Tinggi (m) | 1.8 | 2.6 | 2.6 | 2.6 |

| Ketebalan pisau (mm) | 30 | 40 | 40 | 40 |

| Ketebalan pelat (mm) | 16 | 20 | 30 | 30 |

Selain model yang tercantum di atas, Shuliy juga menyediakan lebih banyak penghancur plastik dengan spesifikasi dan kekuatan berbeda untuk memenuhi kebutuhan industri dan pelanggan yang berbeda. Jika Anda memiliki pertanyaan atau memerlukan informasi lebih lanjut tentang model lain, jangan ragu untuk menghubungi kami, kami akan dengan senang hati memberikan layanan dan konsultasi kepada Anda.

Penggunaan Mesin Penghancur Botol PET yang Benar

- Pertama-tama, mesin penghancur PET harus ditempatkan dengan mulus untuk mencegah mesin jatuh miring selama pengoperasian. Yang terbaik adalah menempatkannya di ruangan yang datar dan berventilasi, yang secara efektif dapat memastikan pembuangan panas normal motor dan secara efektif memperpanjang masa pakainya.

- Sebelum memulai, putar katrol sabuk dengan tangan untuk memastikan rangka pisau fleksibel dan andal dalam pengoperasiannya serta apakah ada benturan di ruang penghancur. Setelah memulai, diamkan selama 1-2 menit, tidak ada fenomena abnormal sebelum memberi makan.

- Saat menghancurkan, masukkan material dengan kecepatan yang seragam, jangan terlalu banyak sekaligus untuk mencegah penyumbatan ruang penghancuran.

- Jaga kecepatan pengumpanan crusher secara merata untuk mencegah kelebihan beban atau tanpa beban. Melarang logam dan benda keras lainnya memasuki mesin yang dapat menyebabkan kerusakan yang tidak perlu.

- Sebelum menghidupkan mesin penghancur botol plastik untuk kedua kalinya, bersihkan sisa bahan hancur di dalam ruang pemotongan, yang dapat mengurangi hambatan start motor dan memperpanjang umur mesin.

Perawatan Mesin Penghancur Botol PET

- Mesin penghancur botol PET harus ditempatkan pada posisi berventilasi untuk memastikan motor bekerja pembuangan panas, untuk memperpanjang umurnya.

- Periksa secara teratur sekrup perkakas, dan penghancur botol plastik baru setelah 1 jam digunakan, dengan perkakas untuk mengencangkan pisau dinamis, sekrup pisau tetap, untuk memperkuat bilah dan kekencangan antara rangka pisau.

- Bantalan harus diisi dengan pelumas secara teratur untuk memastikan pelumasan antar bantalan.

- Untuk menjamin ketajaman ujung tombak pahat, maka pahat harus selalu diperiksa untuk memastikan ketajamannya dan mengurangi kerusakan yang tidak perlu pada bagian lain yang disebabkan oleh tumpulnya mata pisau.

- Periksa secara teratur apakah sabuk kendur dan kencangkan tepat waktu.

- Penghancur botol PET harus disimpan dengan baik.

Kasus Sukses Mesin Penghancur Botol PET

Mesin penghancur botol PET dapat menghancurkan sebagian besar sampah plastik dan menggunakan kembali sebagian sampah plastik dan ini memainkan peran penting dalam Jalur daur ulang botol plastik PET. Oleh karena itu penghancur sampah plastik sangat populer di Asia Tenggara, Afrika, Timur Tengah, dan Amerika Tengah. Penghancur plastik Shuliy telah berhasil dikirim ke banyak negara lain. Di bawah ini adalah contoh spesifik ekspor.

Instalasi Mesin Penghancur Botol Plastik di Nigeria

Pelanggan asal Nigeria ini berencana membuka pabrik daur ulang plastik di daerah setempat dan membeli mesin daur ulang botol PET dan peralatan pelet plastik dari perusahaan kami. Teknisi kami akan pergi ke area setempat untuk membantu pelanggan melakukan pemasangan di lokasi.

Mesin Penghancur Botol PET Tiba Di Mozambik

Kami telah menerima tanggapan dari pelanggan kami di Mozambik bahwa Mesin penghancur botol PET SL-80 dia memesan dari perusahaan kami telah tiba dengan sukses. Kapasitas mesin ini adalah 1000kg/jam, tenaganya 37+4+3kw, dan tampilan mesin disesuaikan dengan kebutuhan pelanggan.

Bagaimana Cara Membeli Mesin Penghancur Botol Plastik?

Sebagai produsen mesin penghancur botol PET profesional, kami memberi Anda panduan pembelian menyeluruh untuk memastikan Anda dapat memilih penghancur botol PET yang paling sesuai. Pertama, Anda dapat mempelajari lebih lanjut tentang peralatan melalui saluran konsultasi produk kami. Selanjutnya sesuai dengan kebutuhan produksi Anda, kami akan membantu Anda menentukan output dan konfigurasi yang dibutuhkan.

Jika ada persyaratan khusus, kami dapat menyesuaikan paketnya untuk Anda. Setelah menentukan rencana, kedua belah pihak mencapai kesepakatan kerja sama, dan kami akan segera mengatur produksi dan pengiriman peralatan tersebut.

Setelah peralatan tiba, kami menyediakan layanan pemasangan dari pintu ke pintu untuk memastikan kelancaran pengoperasian peralatan. Baik itu layanan pra-konsultasi atau purna jual, kami berdedikasi untuk memberi Anda dukungan dan layanan kualitas terbaik.