El tanque de lavado en caliente de escamas de botellas PET es una máquina especialmente diseñada para líneas de lavado de escamas de botellas PET, diseñada para eliminar de manera efectiva aceites, lodos y residuos de etiquetas de las escamas de botellas y devolverlas a estándares de limpieza.

Al calentar agua y sosa cáustica, la máquina utiliza altas temperaturas y reacciones químicas para limpiar a fondo las escamas de botellas y garantizar que cumplan con altos estándares de calidad para el reciclaje.

Con su alta eficiencia y rendimiento de limpieza estable, la máquina de lavado en caliente de copos de PET se ha convertido en un equipo indispensable e importante en el proceso de reciclaje de copos de botellas de PET.

El video a continuación muestra el uso de una máquina de lavado en caliente de copos de PET en una línea de reciclaje de lavado de plásticos. Después de ver el video, continuaremos mostrándote nuestro equipo.

El papel de la máquina de lavado en caliente de escamas de botellas de PET

La máquina de lavado en caliente de copos de PET juega un papel vital en el proceso de limpieza de los copos de botellas de PET. Específicamente, la máquina es capaz de:

- Eliminación de grasa y moco: Utilizando alta temperatura y sosa cáustica, la grasa y el moco se eliminan completamente de la superficie de las escamas de botella, dejándolas limpias.

- Eliminación de residuos de etiquetado: El proceso de lavado en caliente a alta temperatura puede disolver y eliminar eficazmente los residuos de etiquetado en las botellas y garantizar que la superficie de las botellas esté lisa y libre de residuos.

- Mejora de la eficiencia de limpieza: Al lavar en caliente, se puede mejorar significativamente la eficiencia de limpieza, reduciendo la carga de trabajo y la dificultad de los pasos de limpieza posteriores.

Precauciones para el uso de la máquina

Para asegurar la calidad de los copos de botellas de PET finales, hay varios puntos a tener en cuenta al usar esta máquina:

- Control de temperatura de residuos: Al limpiar, la temperatura del agua debe mantenerse entre 85-95 grados para asegurar resultados óptimos de limpieza.

- Tiempo de lavado: El tiempo de lavado debe controlarse entre 30-45 minutos, demasiado largo o demasiado corto puede afectar el efecto de limpieza.

- Uso de sosa cáustica: Es necesario agregar una cantidad apropiada de sosa cáustica para asegurar que el pH del proceso de limpieza sea menor o igual a 8%.

- Mantenimiento regular: Las máquinas requieren inspección y mantenimiento regulares para asegurar que estén funcionando en condiciones óptimas y prolongar su vida útil.

Ventajas del tanque de lavado caliente de escamas de PET

Lavado altamente eficiente

El tanque de lavado caliente utiliza agua a alta temperatura de 85-95 grados para el lavado, y puede disolver de manera efectiva la grasa y los residuos de etiquetas en la superficie de las escamas de botella. El efecto de limpieza se mejora aún más al añadir una cantidad adecuada de sosa.

Eliminación exhaustiva de residuos de etiquetas

La combinación de alta temperatura y sosa cáustica disuelve eficazmente las etiquetas y adhesivos, asegurando que no haya residuos en la superficie de las escamas de botella y mejorando la calidad de las escamas recicladas.

Eficiencia de lavado mejorada

El diseño automatizado del tanque de lavado en caliente permite operaciones de limpieza continuas, reduce la intervención manual y mejora la eficiencia laboral.

Configuraciones personalizadas

Dependiendo de las necesidades de limpieza, la temperatura del agua y el tiempo de limpieza se pueden ajustar para garantizar resultados óptimos de limpieza. De acuerdo con la demanda de la línea de producción del cliente, la capacidad y el modelo de la máquina de lavado en caliente de escamas de botellas PET se pueden configurar de manera flexible para adaptarse a diferentes escalas de la línea de producción.

Parámetros de la Máquina de Lavado en Caliente de Copos de Botellas de PET

| Voltaje | 380V, 50HZ, electricidad trifásica |

| Motor | 4KW |

| Potencia de calefacción electromagnética | 80KW |

| Diámetro | 1300mm |

| Alto | 2000mm |

| Grosor de la pared exterior | 4mm |

| Grosor de la base de la olla | 8mm |

| Método de control | Con armario de control electromagnético separado |

Visualización del tanque de lavado en caliente de copos de botella PET

Línea de lavado recomendada para botellas PET

El tanque de lavado en caliente de escamas de botellas PET es adecuado para líneas de lavado de botellas PET de varios tamaños. Ya sea una pequeña empresa de reciclaje o una planta de procesamiento de plásticos reciclados a gran escala, la máquina puede mejorar eficazmente la calidad de limpieza de las escamas de botellas PET y satisfacer las altas exigencias de reciclaje.

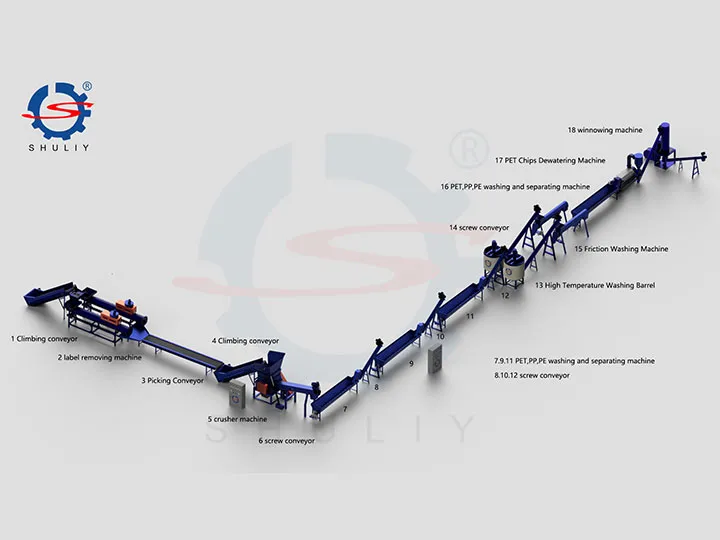

Toda la línea de lavado de botellas PET incluye despegadora de etiquetas de botellas PET, máquina trituradora de botellas PET, máquina lavadora de escamas de PET, máquina deshidratadora de plástico, etc. La línea de reciclaje de botellas de plástico se utiliza principalmente para procesar botellas de plástico, eliminando etiquetas, triturando, limpiando a alta temperatura, deshidratando y secando.

Tenemos una amplia experiencia en la adaptación de soluciones de limpieza y reciclaje, así como en la configuración de equipos según las materias primas y necesidades de los clientes, lo que mejora efectivamente la calidad y la competitividad en el mercado de los materiales reciclados y permite el reciclaje de recursos.