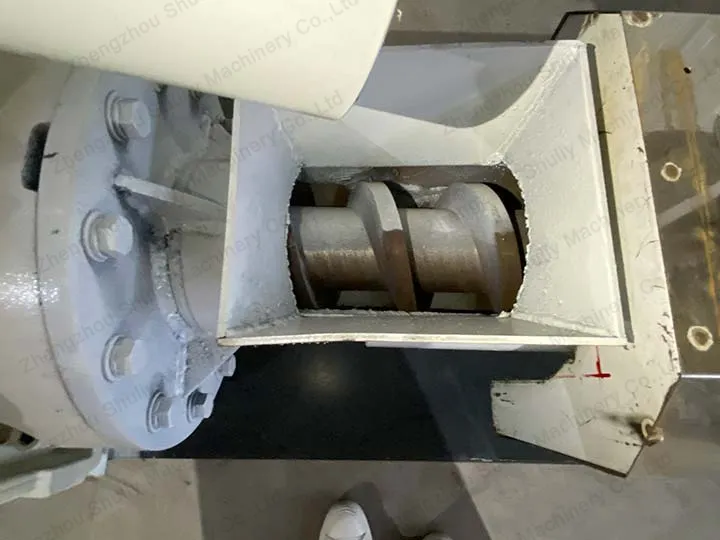

Máy đùn nhựa đóng vai trò quan trọng trong lĩnh vực chế biến nhựa hiện đại, và trục vít là một trong những bộ phận chính, việc vệ sinh và bảo trì trục vít đặc biệt quan trọng. Phương pháp làm sạch trục vít đúng cách không chỉ giúp kéo dài tuổi thọ thiết bị mà còn đảm bảo chất lượng và hiệu quả sản xuất. Trong bài viết này, chúng tôi sẽ giới thiệu cách làm sạch trục vít máy đùn nhựa một cách chính xác để đảm bảo hoạt động ổn định của thiết bị và chất lượng chế biến nhựa.

Tại sao bạn cần làm sạch vít của máy tạo hạt nhựa?

Con vít là một thành phần quan trọng của máy ép nhựa, ảnh hưởng trực tiếp đến chất lượng nhựa được xử lý và sản lượng. Theo thời gian, các cặn nhựa, hạt và bụi bẩn khác tích tụ trên bề mặt của con vít, điều này có thể dẫn đến quá trình xử lý không ổn định, giảm chất lượng và thậm chí là hỏng hóc thiết bị. Việc vệ sinh định kỳ con vít có thể duy trì độ trơn tru và sạch sẽ của bề mặt nó và đảm bảo hiệu suất làm việc hiệu quả của máy tạo hạt nhựa.

Chuẩn bị dụng cụ vệ sinh

Trước khi làm sạch vít của máy ép nhựa, bạn cần chuẩn bị các công cụ sau:

- Bàn chải làm sạch: Chọn bàn chải phù hợp với kích thước và chất liệu của vít để loại bỏ bụi bẩn trên bề mặt.

- Chất tẩy rửa: Chọn chất tẩy rửa phù hợp, chẳng hạn như chất tẩy rửa nhựa, để hòa tan và loại bỏ các cặn bẩn cứng đầu.

- Khăn lau: để lau bề mặt vít nhằm đảm bảo việc làm sạch kỹ lưỡng.

Quy trình vệ sinh vít máy ép nhựa

Ngừng hoạt động và vận hành an toàn

Luôn tắt hoàn toàn máy ép nhựa và ngắt kết nối nguồn điện trước khi vệ sinh. Ngoài ra, hãy đảm bảo rằng tất cả các biện pháp an toàn đã được thực hiện để tránh bất kỳ tai nạn nào. An toàn luôn là yếu tố hàng đầu.

Tháo vít

Tùy thuộc vào mô hình và cấu trúc của máy ép viên nhựa, việc tháo vít có thể yêu cầu một số kiến thức kỹ thuật và công cụ. Cẩn thận tháo rời vít và các bộ phận liên quan theo hướng dẫn sử dụng do nhà sản xuất cung cấp. Đảm bảo rằng mỗi bước được ghi lại để có thể hoạt động chính xác trong quá trình lắp ráp lại.

Vệ sinh vít

Làm sạch bề mặt của ốc vít một cách nhẹ nhàng bằng cách sử dụng các chất tẩy rửa và công cụ phù hợp. Không nên sử dụng công cụ sắc nhọn để tránh làm xước bề mặt. Tùy thuộc vào mức độ nghiêm trọng của dư lượng nhựa, có thể cần nhiều lần làm sạch. Đảm bảo rằng chất tẩy rửa không làm hỏng vật liệu của ốc vít.

Chú ý đến bên trong của ốc vít

Vệ sinh bên ngoài của vít cũng quan trọng không kém, nhưng đừng bỏ qua bên trong của vít. Sử dụng các công cụ và phương pháp phù hợp, cẩn thận loại bỏ bất kỳ cặn bẩn nào có thể đã bám vào rãnh của vít. Điều này sẽ ngăn ngừa ô nhiễm và tắc nghẽn trong tương lai để đảm bảo chất lượng quy trình.

Biện pháp phòng ngừa

- Trong quá trình làm sạch, tránh sử dụng các công cụ sắc nhọn hoặc vật cứng để cạo bề mặt của vít máy ép nhựa nhằm tránh trầy xước.

- Chọn các chất tẩy rửa phù hợp và tránh sử dụng hóa chất có thể gây ăn mòn trên vít của máy tạo hạt nhựa.

- Đảm bảo rằng máy ép nhựa được tắt nguồn và hoàn toàn nguội trong quá trình làm sạch để đảm bảo an toàn cho cá nhân.

- Việc làm sạch định kỳ vít sẽ giúp kéo dài tuổi thọ của máy tạo viên nhựa và duy trì chất lượng sản phẩm đồng nhất.