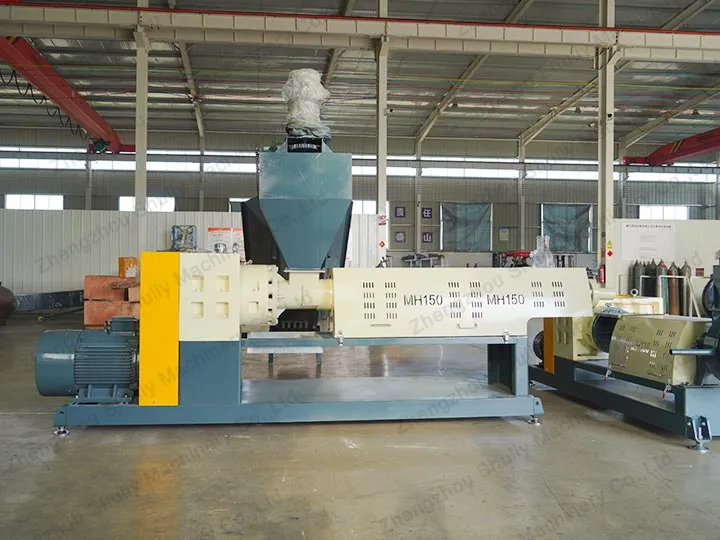

Máy ép viên tái chế nhựa được sử dụng rộng rãi, chủ yếu để chuyển đổi nhựa thải thành viên nhựa chất lượng cao để sử dụng trong sản xuất các sản phẩm tái chế. Thông qua việc xử lý vật lý hợp lý, thiết bị tạo hạt nhựa có thể tái chế nhựa thải, giảm ô nhiễm môi trường và thực hiện tái chế tài nguyên. Hôm nay, chúng tôi sẽ giới thiệu cho bạn một bộ ảnh mới nhất về máy ép viên tái chế nhựa tại nhà máy của chúng tôi.

Lợi thế độc đáo của thiết bị tạo hạt nhựa Shuliy

Cốt lõi của nhà máy máy tạo viên nhựa là công nghệ và lợi thế độc đáo của máy tạo viên nhựa tái chế.

- Hiệu suất cao: Máy nghiền viên nhựa tái chế Shuliy được biết đến với năng suất vượt trội. Công nghệ viên nén tiên tiến xử lý hiệu quả nhựa thải thành viên nén, giảm tiêu thụ năng lượng và tăng năng suất.

- Tính ổn định: Tính ổn định là rất quan trọng trong quy trình ép viên nhựa. Máy nghiền Shuliy tái chế nhựa đáp ứng các yêu cầu chất lượng sản phẩm nghiêm ngặt của khách hàng bằng cách đảm bảo kích thước viên đồng đều với hệ thống điều khiển chính xác.

- Tùy chỉnh: Các loại nhựa khác nhau yêu cầu các phương pháp xử lý khác nhau. Máy nghiền viên nhựa tái chế Shuliy cung cấp nhiều tùy chọn tùy chỉnh để phù hợp với các loại nhựa và yêu cầu quy trình khác nhau, mang đến cho khách hàng các giải pháp cá nhân hóa.

- Điều khiển tự động: Được trang bị hệ thống điều khiển tự động tiên tiến, người dùng có thể dễ dàng thiết lập và điều chỉnh các tham số sản xuất để thực hiện việc kiểm soát chính xác quy trình sản xuất, nhằm thu được các viên nhựa phù hợp hơn với nhu cầu.

Hình ảnh nhà máy máy nghiền viên nhựa tái chế

Dù bạn quan tâm đến ngành công nghiệp tái chế nhựa hay là công chúng lo ngại về bảo vệ môi trường, chúng tôi chân thành chào đón bạn đến thăm nhà máy máy tạo viên nhựa Shuliy và xem các máy hoạt động. Chúng tôi biết rằng khi thấy các máy hoạt động, bạn sẽ hiểu rõ hơn về cách chúng hoạt động và vai trò của chúng trong việc tái chế nhựa. Nếu không tiện đến nhà máy, bạn cũng có thể yêu cầu báo giá máy tạo hạt nhựa và các chi tiết khác bằng cách để lại tin nhắn hoặc gửi tin nhắn.

Cách chọn máy tạo hạt nhựa phù hợp?

Làm thế nào để chọn máy tạo hạt nhựa phù hợp với nhu cầu của bạn? Đây chắc chắn là mối quan tâm của nhiều doanh nhân quan tâm đến việc tái chế nhựa. Trong chuyến tham quan nhà máy, nhân viên đã chia sẻ một số kinh nghiệm về cách chọn máy tạo hạt nhựa tái chế phù hợp.

- Trước tiên, cần xác định đúng mô hình theo loại nhựa. Các loại nhựa khác nhau có thể yêu cầu các quy trình xử lý khác nhau, vì vậy bạn cần đảm bảo rằng máy ép viên nhựa tái chế mà bạn chọn có thể đáp ứng được yêu cầu sản xuất. Cũng quan trọng là phải xem xét các yếu tố ngân sách để đảm bảo rằng máy được chọn có sự cân bằng giữa hiệu suất và giá cả.

- Thứ hai, bạn cần chọn thông số kỹ thuật phù hợp với quy mô sản xuất của mình. Nếu quy mô sản xuất lớn, thì sẽ có lợi hơn khi chọn máy tạo hạt nhựa có công suất cao hơn. Ngoài ra, hãy chú ý đến các thông số hiệu suất của máy, chẳng hạn như tốc độ xử lý, mức tiêu thụ năng lượng, v.v. Những chỉ số này có liên quan trực tiếp đến hiệu quả sử dụng của máy tạo viên tái chế nhựa và kiểm soát chi phí.

- Một lần nữa, hãy chú ý đến độ bền của máy và sự dễ dàng trong việc bảo trì. Một máy ép viên bền có thể mang lại lợi ích sản xuất lâu dài hơn, trong khi một thiết kế dễ bảo trì có thể giảm thời gian ngừng sản xuất và chi phí sửa chữa.

- Cuối cùng, hãy chọn các nhà sản xuất có dịch vụ hậu mãi đáng tin cậy. Dịch vụ hậu mãi tốt có thể cung cấp hỗ trợ kỹ thuật và dịch vụ bảo trì kịp thời khi máy móc gặp sự cố, để đảm bảo sự liên tục trong sản xuất. Shuliy là một thương hiệu nổi tiếng trong ngành, và chất lượng sản phẩm cũng như dịch vụ hậu mãi của nó được công nhận cao, xứng đáng với sự tin tưởng của bạn.