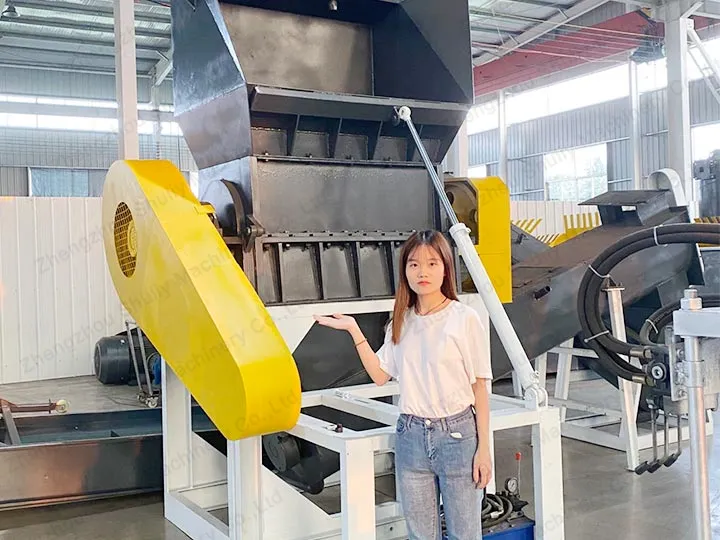

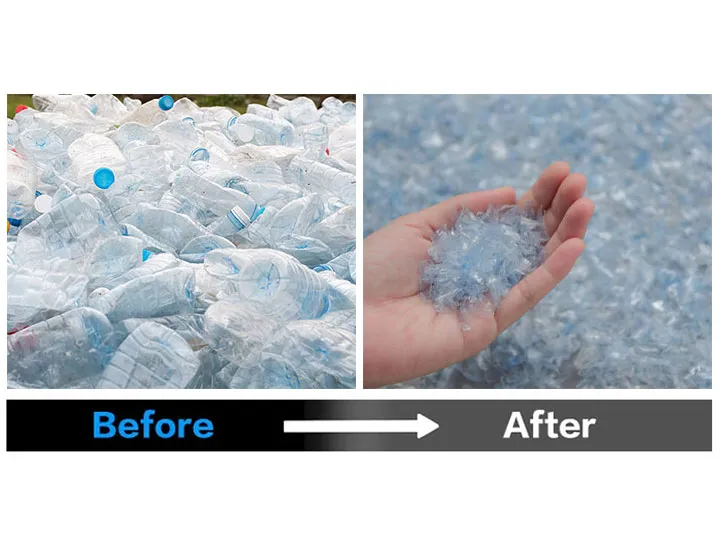

Mashine ya kusagia chupa za plastiki ni mojawapo ya vifaa muhimu zaidi katika Laini ya kuosha chupa za PET, hutumiwa sana kwa kusaga chupa za plastiki.

Chupa za plastiki zinakatwa kuwa karatasi nyembamba na mashine ya kukata chupa za plastiki na plastiki hii inaweza kurejelewa na kutumika kwa urahisi. Mashine ya kukata chupa za plastiki inatumika sana katika sekta mbalimbali. Aina tofauti za bidhaa za plastiki zinaweza kukatwa na kisha kurejelewa, kupunguza sana madhara ya uchafuzi mweupe kwa mazingira yetu.

Installation och idrifttagning av plastflaskkrossmaskin

- Om tillverkaren har en viss plan för placeringen av sin produktionsverkstad och avser att placera och använda plastflaskkrossmaskinen under en lång tid, kan de låsa krossen med fotbulten som är förberedd i betongen. Detta kan förbättra en del av styvheten hos utrustningen och minska det ljud som genereras vid arbete. Om den ofta används mobilt kan du informera tillverkaren i förväg och installera universella hjul längst ner för att underlätta förflyttning.

- Mashine ya kusaga chupa za plastiki inapaswa kuwekwa kulingana na mahitaji ya mistari ya kusaga na kusafisha ili kuepuka mazingira ya kukwama kwa mvua iliyofungwa, ambayo si ya kufaa kwa kuondoa joto kwa kawaida kwa motor kavu.

- Var uppmärksam på den horisontella installationen av utrustningen och marken.

- Efter att installationen är klar behöver plastflaskkrossmaskinen kontrollera om alla låsmuttrar är lösa innan användning (tillverkaren kommer att kontrollera detta innan den lämnar fabriken och kan inte helt garantera att de inte blivit lösa på grund av logistik och transport, vilket naturligtvis tillhör några få fall).

- Kabeldragning måste baseras på den nominella effekten och strömmen av utrustningen för att välja tjockleken på huvudkabeln och storleken på luftbrytaren.

Försiktighetsåtgärder vid användning av plastflaskskrossen

- Innan du startar plastflaskkrossen, kontrollera om spindelns rotation är normal och justera den i tid om det finns någon avvikelse. Vänta på att plastkrossen ska fungera normalt innan du kastar in material.

- Stoppa att kasta avfallsmaterial 15 minuter innan plastflaskkrossen stänger av, och stäng av kontrollkraften i ordning efter att materialet har krossats noggrant. Rengör sedan de kvarvarande materialen i plastflaskkrossen och knivramen, särskilt om skärmen är blockerad, om kniven är lös, osv.

- Hakikisha kwamba mashine ya kukata chupa za plastiki inapata malighafi kwa usawa na kuzuia kupita kiasi. Zuia vitu vya chuma, mbao, na vitu vingine visivyoweza kuvunjika kuanguka ndani ya mashine.

- Tafadhali zingatia mabadiliko ya joto la shat ya kuu wakati wa kila operesheni ya kusaga ya crusher ya kipindi. Ikiwa joto la shat ya kuu liko juu sana, angalia mafuta ya kuzaa kwa wakati baada ya kusimama. Kabla ya kusimama kwa operesheni, simamisha kulisha na kutoa ya mashine, kisha kata nguvu ya motor.

- I användning varje dag kan plastkrossen endast ge en mer framträdande krossningseffekt om den underhålls och sköts ordentligt. Kunder som vill förlänga livslängden på krossen kan strikt reglera operatörens beteende och minska felanvändning för att säkerställa effektiv och säker drift av maskineriet.

Underhåll av PET-flaskkrossmaskin

- Lageret motsvarar en av de viktiga delarna av PET-flaskkrossmaskinen, och bra smörjning kommer att ge längre livslängd åt lagret. Därför behöver operatören fylla på smörjmedlet regelbundet, och det rekommenderas att använda tillverkarens rekommenderade modell.

- Tazama hali ya kazi ya mashine ya kusaga chupa za PET mara kwa mara, na simamisha mashine mara moja ili kuangalia kama kuna kelele za ajabu na matatizo mengine.

- Var uppmärksam på att kontrollera slitage på slitdelar (rem, krossblad, plastkrosskärm, etc.) och håll ett öga på att byta ut slitna delar.

- Tazama joto la kubeba wakati wa uendeshaji na hakikisha kwamba kubeba kuna mafuta vizuri. Wakati joto la mafuta ya kubeba linapoongezeka, simama mara moja ili kuangalia sababu na kuondoa hiyo. Tazama sauti na mtetemo ikiwa kuna hali isiyo ya kawaida. Wakati hali zisizo za kawaida zinapogundulika, simama mashine ili kuangalia ikiwa imekwama na vitu visivyovunjika au ikiwa sehemu za mashine zimeharibiwa.

- Hakikisha vifaa ndani na nje vinakuwa safi na vya mpangilio. Kufanya urejeleaji wa plastiki taka hakuepukiki kuwasiliana na mafuta, viwanja kemikali, nk., ambavyo vitabaki kwenye zana na skrini kwa muda mrefu bila kusafishwa, na hata kuharibika kwa vifaa.