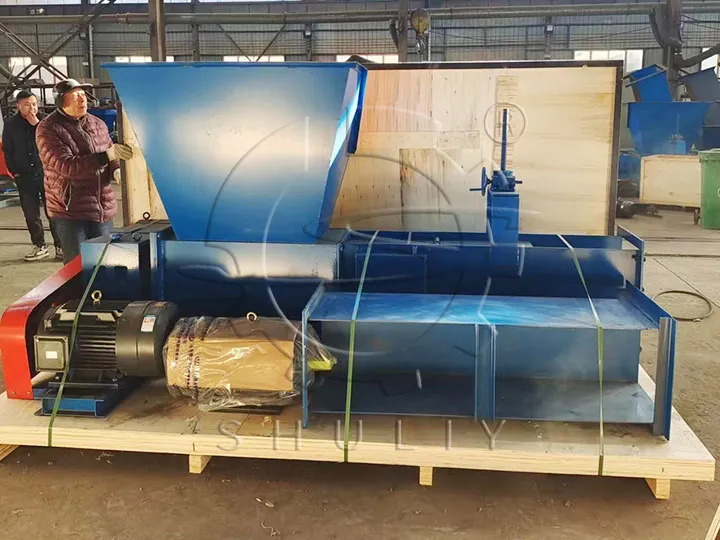

God nyhet! Shuliy EPS-skum kompakta maskin har framgångsrikt skickats till USA, vilket ger en effektiv lösning för återvinning av EPS-skum.

Kanuni ya mashine ya kufinya povu la EPS

Kompaktori ya EPS ni vifaa vya kitaalamu vya kuchakata taka ya povu, kanuni yake ni kubana povu la taka kwa shinikizo la baridi la mitambo, kupunguza ujazo na kuongeza wiani, ili kufikia athari ya kupunguza gharama za kuhifadhi na usafirishaji. Mashine ya kubana povu ya EPS ya Shuliy inatumia teknolojia ya kisasa kuhakikisha kuwa nyenzo inabana kwa ufanisi na kuokoa nishati wakati wa mchakato wa matibabu bila kuathiri utendaji wa asili wa nyenzo.

Kompaktorn för EPS-skum skickad till Amerika

Funktioner för kallpressmaskin för EPS-skum

- Effektiv kompression: Den Mashine ya baridi ya kufinya povu la EPS använder avancerad kompressionsteknik, kapabel att komprimera stora volymer EPS-skum till kompakta block på kort tid, vilket maximerar kompressionseffektiviteten.

- Ulinzi wa mazingira na uhifadhi wa nishati: Matumizi ya teknolojia ya kisasa ya ulinzi wa mazingira hupunguza matumizi ya nishati na kukidhi mahitaji ya jamii ya leo kwa maendeleo endelevu na ulinzi wa mazingira. Matumizi ya mashine ya kufinya povu ya EPS husaidia kupunguza mzigo wa taka kwa mazingira.

- Rahisi kutumia: Densifier ya styrofoam ya EPS foam inayoshinikizwa baridi imetengenezwa kwa kuzingatia uzoefu wa mtumiaji, na ni rahisi na rahisi kutumia, ikipunguza kigezo cha matumizi na kuwezesha kampuni na mashirika zaidi kufanikisha kwa urahisi upya wa ufanisi wa EPS foam.