私たちの剛性プラスチックシュレッダー機は、廃プラスチックを処理するために設計された機械および設備の一種です。廃プラスチック製品を正確に切断し、粉砕して再利用可能な小さな部品にすることができます。シュリィプラスチッククラッシャーの出力は600〜1200kg/hであり、プラスチックリサイクルに強力なサポートを提供します。

剛性プラスチックシュレッダー機の適用範囲

剛性プラスチックシュレッダー機は、プラスチックリサイクル業界やプラスチック製品メーカーで広く使用されています。これは、PETボトル、PVCパイプ、HDPEシートなど、さまざまな剛性プラスチック廃棄物を処理することができます。これらの剛性プラスチック廃棄物は、廃棄された後に分解されにくく、環境に深刻な問題を引き起こします。産業用プラスチックシュレッダー機を使用することで、これらの廃棄物を効率的に小さな破片に粉砕し、その後の再処理やリサイクルが可能になります。

剛性プラスチックとは?

剛性プラスチックは、硬くて強く、使用していないときでも形状を保持するプラスチック材料です。さまざまな熱成形プロセスを通じて製造され、バケツ、スプリンクラー、プランター、ガーデンファニチャー、ランドリーバスケット、ゴミ箱、パイプなどの製品が含まれます。

剛性プラスチックは、柔らかくてしなやかな柔軟プラスチックとは異なり、柔軟プラスチックはプラスチック袋、包装フィルム、シュリンクラップなどの製品に一般的に使用されています。両方のタイプのプラスチックはリサイクル可能ですが、剛性プラスチックはそのサイズと形状のため、通常はリサイクルが難しいです。

しかし、先進のプラスチックリサイクル技術と機械を使用することで、剛性プラスチックのリサイクルはより効率的かつ効果的になり、廃棄物を減らし、持続可能な処理方法を促進する重要なステップとなっています。

硬質プラスチックシュレッダーの作動原理

産業用プラスチックシュレッダー機の動作原理は、刃の高速回転と硬いプラスチックの衝突摩擦に基づいています。硬いプラスチックが破砕室に入ると、硬いプラスチッククラッシャー機の刃が素早く切断し、小さな破片に砕きます。

多くの切断と衝撃の後、硬いプラスチックは最終的に必要なサイズに粉砕されます。このプロセスでは、硬いプラスチッククラッシャー機のスクリーンが仕分けの役割を果たし、仕様を満たす部分を通過させ、最終製品の品質を確保します。

プラスチックシュレッダー機の設計 および構造

投入口

剛性プラスチックシュレッダー機は、さまざまなサイズのプラスチック製品に対応するために広い給餌口を備えています。自動給餌装置によって、連続的かつ効率的な作業フローが実現されています。

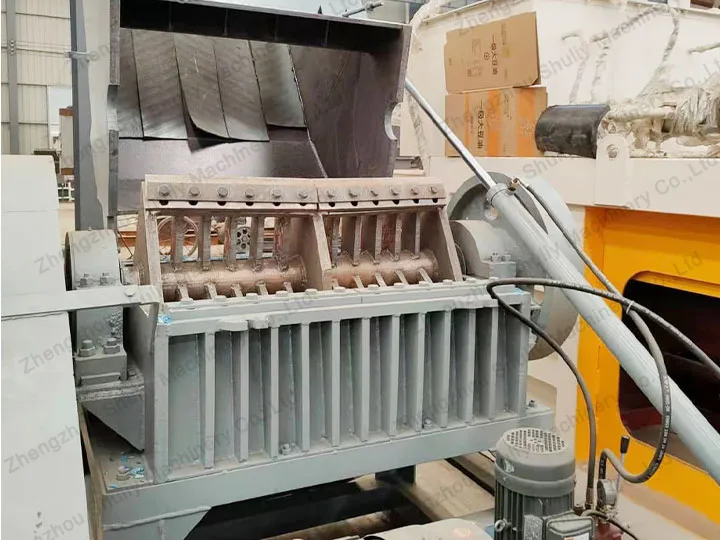

粉砕室

破砕室内のブレードの配置は、プラスチック製品が均等かつ効率的に破砕されるように慎重に設計されています。廃プラスチックシュレッダーの内部構造の最適化により、エネルギー消費が削減され、破砕効率が向上します。

ブレード

廃プラスチック粉砕機は、多角度および多層刃設計を採用しており、さまざまな種類の剛性プラスチックを効果的に切断できます。プラスチック粉砕機の刃の材料の選定は厳密にテストされており、長寿命を保証します。

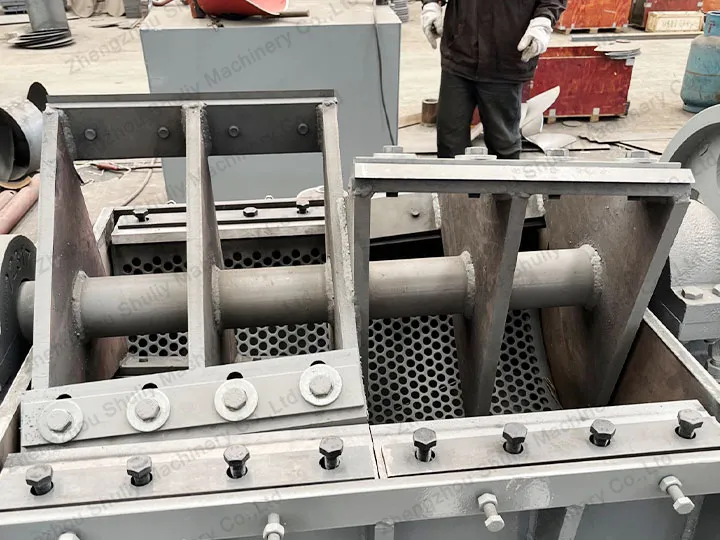

スクリーン

粉砕プロセス中に、微細な粒子はプラスチック材料のシュレッダーのスクリーンを通過させて、最終製品の均一なサイズを確保する必要があります。硬いプラスチックの場合、スクリーンの直径は通常20mmから26mmです。

プラスチック材料のシュレッダー用スクリーンメッシュは、さまざまなニーズに応じて交換可能で、異なるアプリケーションシナリオに適応します。適切なスクリーンを取得するために、いつでもShuliyにお問い合わせください。

剛性プラスチック用シュレッダーのパラメータは何ですか?

これらのプラスチック廃棄物シュレッダー機は、さまざまな電力と処理能力を持つShuliyのプラスチッククラッシャーの人気モデルで、異なるサイズとニーズのプラスチック破砕作業に対応しています。これらは先進的な破砕技術を利用し、複数の回転刃を備えており、プラスチック材料を望ましいサイズに効果的に粉砕します。各廃プラスチック破砕機モデルは、回転刃の数や直径、供給口のサイズが異なるため、ユーザーは特定のニーズに応じて適切なモデルを選択できます。

| 容量 | SL-600 | SL-800 | SL-1000 |

| 電力 | 30 kW | 45 kW | 55 kW |

| 容量 | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| ブレード幅 | 600cm | 800cm | 1000cm |

| ブレードの材料 | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| ブレードの数量 | 10個 | 10個 | 10個 |

上記のモデルに加えて、Shuliyはさまざまなサイズと構成のハードプラスチックシュレッダーを幅広く提供しており、特定のニーズに合わせてカスタマイズできます。詳細やカスタマイズのニーズについてお気軽にお問い合わせください。

産業用プラスチックシュレッダー機の特徴

非常に効率的な破砕能力

剛性プラスチックシュレッダー機は、強力な駆動装置と特別な刃を採用しており、剛性プラスチック製品を迅速に小さな断片に切断して処理効率を向上させることができます。剛性プラスチックシュレッダー機の刃のピッチと速度は調整可能で、希望するチップサイズを得ることができ、ユーザーの異なる再処理ニーズに応じた機械の柔軟性を高めます。

耐久性と安定性

産業用プラスチックシュレッダーは頑丈な構造を持ち、高品質の材料で作られています。長時間安定して稼働でき、さまざまな種類の硬いプラスチックに適応し、メンテナンスコストを削減します。

高い安全性

オペレーターの安全を考慮して、剛性プラスチックシュレッダー機は複数の安全装置を備えています。自動停止装置、緊急停止ボタン、保護カバーは、操作プロセスのすべての側面で安全を確保します。

多様なニーズに応じてカスタマイズ可能

すべての業界とすべての企業には異なるニーズがあります。シュリィは、プラスチッククラッシャーのパラメータ、外観、構成を顧客の特定の要件に適応させるためのカスタマイズオプションを提供しています。これにより、剛性プラスチックシュレッダー機械がさまざまなプラスチック廃棄物の特性に最適に適応し、可能な限り最高の結果を達成することが保証されます。

廃プラスチッククラッシャー機のプロセス動画

成功事例:世界市場向け廃プラスチッククラッシャー

ガーナに送られたプラスチックシュレッダー機

SL-600剛性プラスチックシュレッダーマシンは、Shuliyによって発売され、ガーナに成功裏に販売されました。この機械は、その強力なパワーと効率的な生産性能で顧客の支持を得ています。廃プラスチックを効率的に粉砕し、廃プラスチックのリサイクルの次のステップを促進し、顧客のリサイクル効率を向上させ、収益を増加させます。

ケニアに出荷されたプラスチックリサイクル設備

ケニアのプラスチックリサイクル工場のオーナーは、廃プラスチックの処理を改善するために、Shuliyから一式のプラスチックリサイクル設備をカスタマイズしました。プラスチックリサイクル設備は運転を開始し、顧客はこれらのリサイクル機械に非常に満足しています。

剛性プラスチックシュレッダー機 リサイクルプラントで

PETボトルリサイクルプラント

PETボトルリサイクルプラントには、1台の剛性プラスチックシュレッダーマシン、1台の洗浄タンク、1台のプラスチック脱水機、及び再利用のためのプラスチック廃棄物を清掃・リサイクルするために使用される他の機械が含まれています。

プラスチック廃棄物を効率的かつコスト効果的に処理したい場合は、お気軽にお問い合わせください。私たちのプロジェクトマネージャーが、あなたのためにリサイクルソリューションをカスタマイズします。私たちは、あなたの材料の清浄度と最終製品の要件に応じて、ソリューションと機械を設計します。

PP PEプラスチックリサイクルプラント

PP PEプラスチックリサイクルプラントには、剛性プラスチックシュレッダーマシン、プラスチック洗浄タンク、プラスチックリサイクルペレット化機械、プラスチック粒子カッター、及びプラスチック廃棄物をペレット化・リサイクルするために使用される他のプラスチックリサイクル機械が含まれています。廃プラスチックがあり、それにどう対処すべきかわからない場合は、ぜひご連絡ください!廃材料を処理しながら経済的利益を得るために、専門的なアドバイスと先進的なプラスチックリサイクル設備を提供します。

ハードプラスチックシュレッダーの価格についてのお問い合わせ!

硬質プラスチックのリサイクル方法をご存知ですか?急いでご連絡ください!当社の営業マネージャーが、プラスチッククラッシャーのモデルやその他の要因に応じて、硬質プラスチックシュレッダー機の価格やプラスチックシュレッダー機のその他の詳細をできるだけ早くお知らせし、最適なソリューションと最も有利なオファーを提供いたします。