プラスチック廃棄物クラッシャーは、廃プラスチックやその他の材料を処理するための重要な機器であり、環境保護や廃棄物の再利用において重要な役割を果たしています。

しかし、長期間の使用や不適切な操作により、プラスチック廃棄物粉砕機は一般的な問題が発生することがあります。この記事では、プラスチック廃棄物粉砕機の3つの一般的な故障を紹介し、それに対する対応策を提供して、効率的な運転と長持ちする使用を確保します。

プラスチック廃棄物粉砕機の詰まり問題

問題の説明

プラスチック材料のシュレッダーは詰まる可能性があり、プラスチック廃棄物のスムーズな処理を妨げます。

考えられる原因

詰まりは、廃棄物が大きすぎたり硬すぎたりすること、または廃棄物の蓄積をタイムリーに取り除かないことが原因で発生する可能性があります。

ソリューション

- 定期メンテナンス:プラスチック材料シュレッダーのブレードとスクリーンを、使用後に定期的にチェックして、残留プラスチックの破片がないことを確認し、詰まりの問題を避けてください。

- 適切な給餌:プラスチック廃棄物のサイズと硬さがプラスチック材料シュレッダーの処理能力に適していることを確認するために、給餌の量を制御し、廃棄物が大きすぎたり硬すぎたりすることによる詰まりを防ぎます。

- 定期的な清掃:長期間使用した後は、プラスチック材料シュレッダーの内部を定期的に清掃し、蓄積された廃棄物を取り除いて詰まりを防ぐ必要があります。

プラスチック廃棄物粉砕機の騒音問題

問題の説明

使用中、廃プラスチック粉砕機が異常な音を発生させることがあり、作業環境や機器の寿命に影響を与えます。

考えられる原因

騒音問題は通常、機器の摩耗、不均衡、または緩んだ部品が原因です。

ソリューション

- 潤滑とメンテナンス:廃プラスチック粉砕機の主要部分を定期的に潤滑し、メンテナンスを行うことで、摩耗と摩擦を減らし、騒音を低減します。

- 部品を締める:すべての部品が緩んでいないことを確認し、特に刃とナイフの座、振動に影響を受けやすい他の部品を締めてください。

- バランスキャリブレーション:廃プラスチック粉砕機の回転部分のバランスを調整し、機器が高速度で振動や騒音を少なくして動作することを確保します。

過負荷保護の問題 プラスチック廃棄物クラッシャーの

問題の説明

プラスチック廃棄物クラッシャーが過負荷になると、ユニットが動作を停止したり、部品が損傷したりすることがあります。

考えられる原因

過負荷は通常、連続運転が多すぎるか、プラスチッククラッシャーに供給される材料が多すぎることが原因です。

ソリューション

- 作業時間の合理的な配分:プラスチック粉砕機を使用する際は、長時間の連続作業を避け、機器に十分な冷却休息時間を与え、過熱や過負荷を防ぐことが重要です。

- 給餌の量を制御する:給餌速度と量を制御し、プラスチックシュレッダーが廃棄物を徐々に処理できるようにし、一度に過剰な廃棄物を投入して過負荷になるのを避ける。

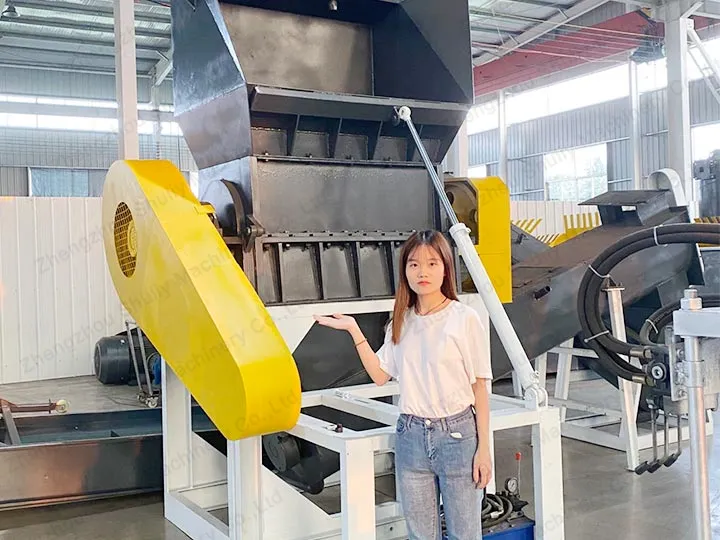

シュリィプラスチック廃棄物クラッシャー

シュリは、高品質で信頼性のあるプラスチック粉砕機を提供する、業界をリードするプラスチック機械メーカーです。シュリのプラスチックシュレッダーは、優れた耐久性と高効率のために、先進技術と高品質の材料で製造されています。

Shuliyのプラスチック廃棄物破砕機にご興味がある場合は、お気軽にお問い合わせください!